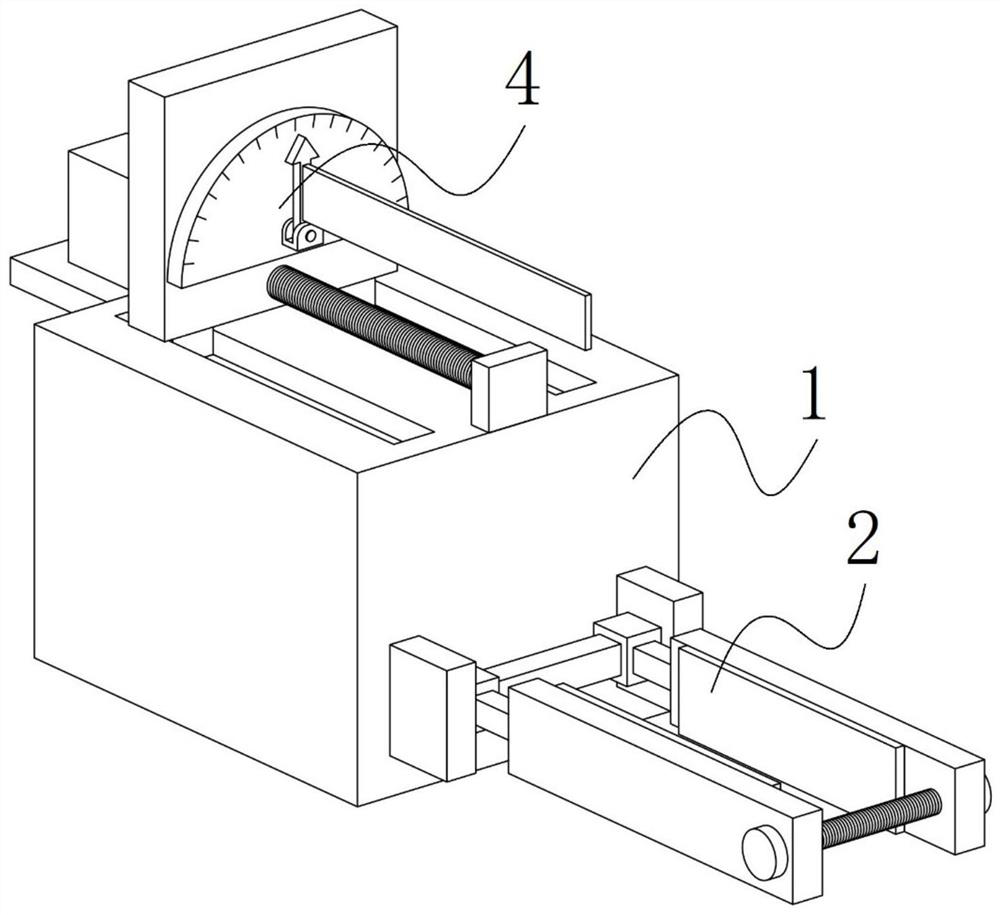

Improved road and bridge rubber support shear deformation detection device

A technology for detection devices and rubber bearings, applied in measuring devices, mechanical measuring devices, mechanical solid deformation measurement, etc., can solve problems such as inability to accurately determine the deformation range, achieve easy access, reduce engineering costs, and facilitate disassembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

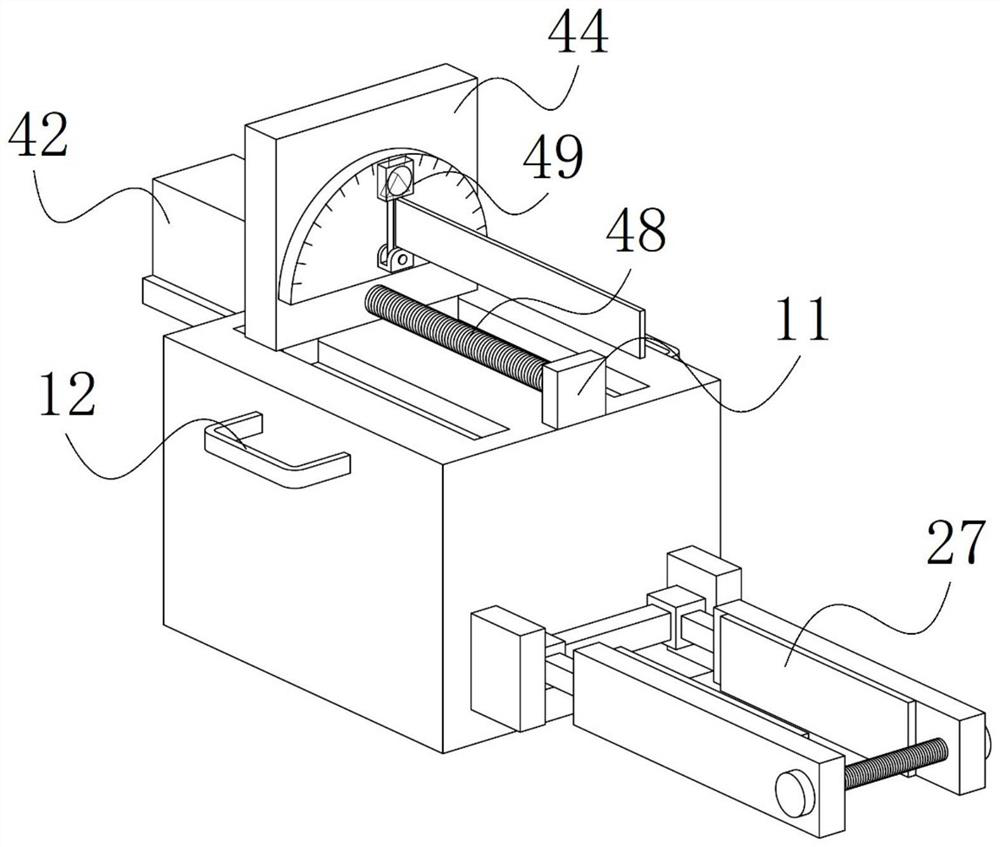

[0076] An improved detection device for the shear deformation of road and bridge rubber bearings with the above-mentioned design structure needs to be installed as a backup before it is used.

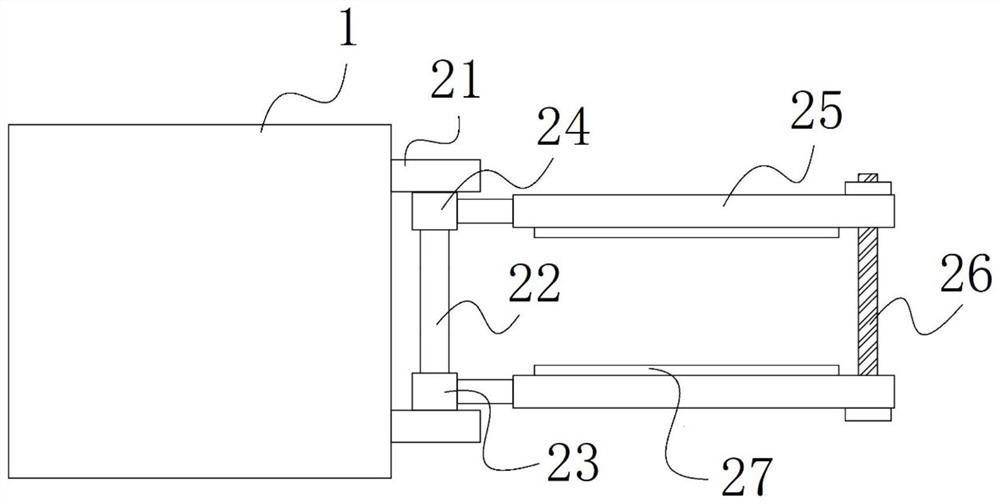

[0077] During installation, first, the operator assembles the clamping assembly 2, which includes a fixed plate 21 symmetrically arranged under one side of the box body 1, and the two fixed plates 21 are connected with a guide rod 22 with a fixed collar 23, and the guide rod The other end of 22 is connected with movable collar 24, and the same end of fixed collar 23 and movable collar 24 all connects the extruded plate 25 with anti-skid pad 27 inboard by connecting rod, passes through bolt between two extruded plates 25 Component 26 is connected. The two extrusion plates 25 are symmetrical to each other.

[0078] Then, the operator installs the box 1 . One side of the box body 1 is provided with an electric storage device 3, and the bottom is provided with a control switch 5, both of ...

Embodiment 2

[0087]The design structure of embodiment 2 is basically the same as that of embodiment 1, the only difference is that the overall structure of the detection assembly 4 is different. The detection assembly 4 of this structure includes a sliding mounting plate 4a, an electric push rod 4b, a detection protractor 4c and an indicator Needle 4d and measuring ruler 4e, wherein, one side of sliding mounting plate 4a is connected with electric push rod 4b, and electric push rod 4b is electrically connected to electric storage device 3, and electric storage device 3 is electrically connected to control switch 5 through wire;

[0088] The other side of the sliding mounting plate 4a is provided with a detection protractor 4c, the detection protractor 4c is provided with an indicator needle 4d, and one side of the indicator needle 4d is connected with a measuring ruler 4e.

[0089] The electric push rod 4b is installed on the support plate 41;

[0090] The detection protractor 4c has a sem...

Embodiment 3

[0097] The design and structure of embodiment 3 and embodiment 1 and embodiment 2 are basically the same, and the only difference is that the four corners of the bottom of the box body 1 are also provided with a moving device 13, and the moving device 13 is a directional wheel or a universal wheel. The directional wheel or the universal wheel are provided with a braking device matched with it to complete the work.

[0098] The design of the structure realizes the flexible and convenient movement during the actual working process, and reduces the labor intensity of the operator to the greatest extent;

[0099] The specific installation and use are the same as in Embodiment 1 and Embodiment 2, and will not be repeated here.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap