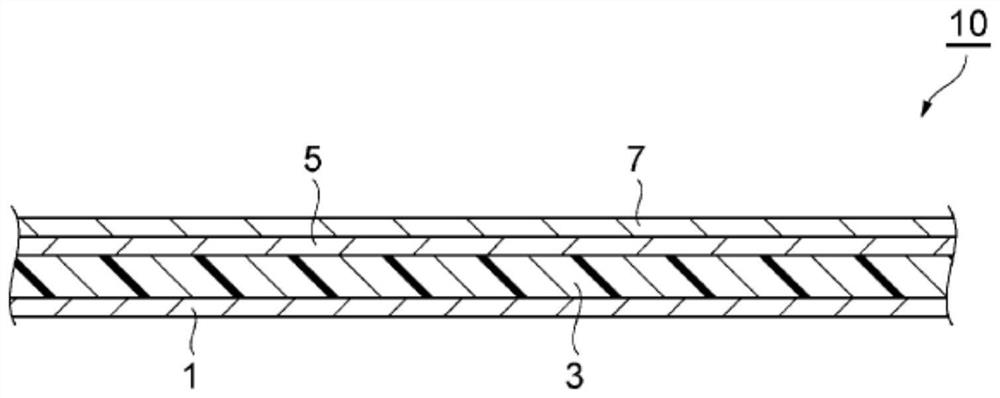

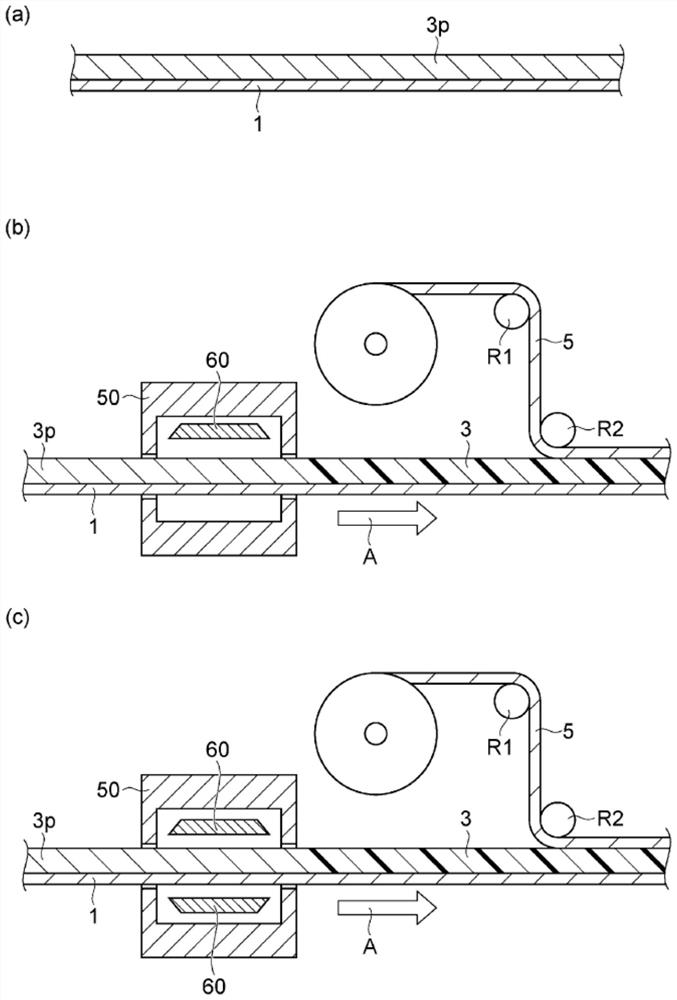

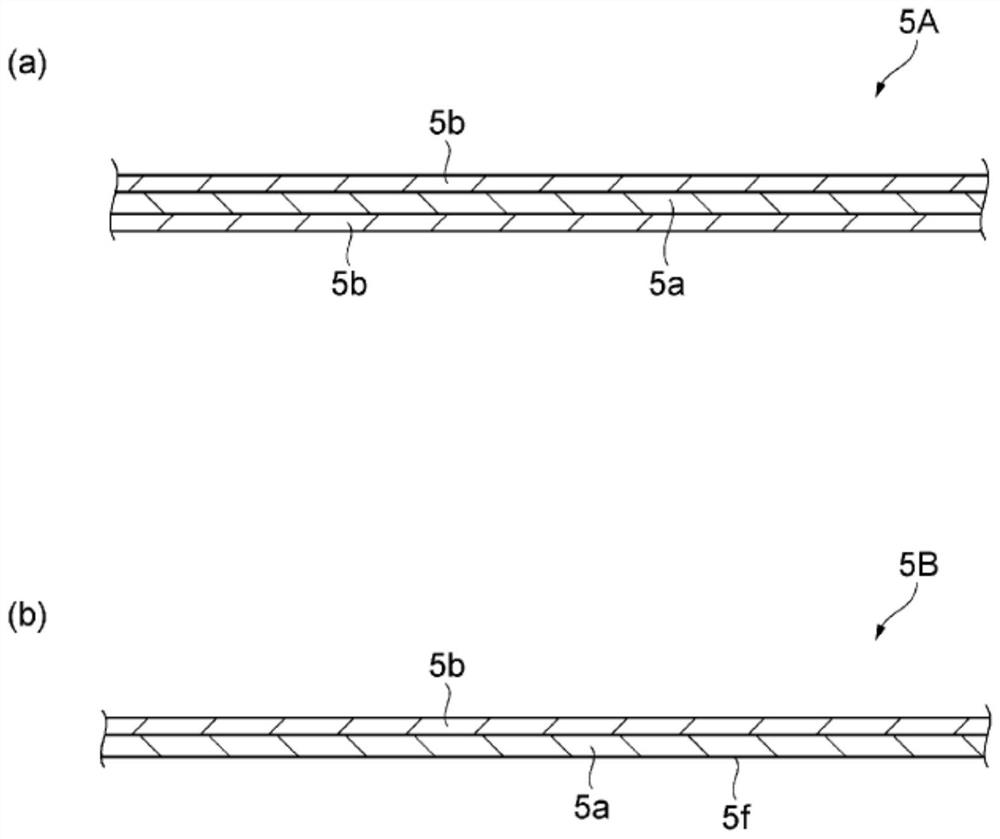

Method for producing heat storage sheet

A manufacturing method and technology of heat storage sheets, applied in the direction of chemical instruments and methods, lamination, lamination devices, etc., can solve the problems of application field limitation, fire, ignition, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~ Embodiment 5

[0203] Each component was heat-mixed at 50 degreeC by the compounding ratio shown in Table 1, and the curable composition was obtained. Next, under the condition of 50° C., the curable composition was applied onto the PET film using a bar coater so that the thickness of the cured heat storage layer became 200 μm. The photocuring treatment of the heat storage layer was performed by irradiating ultraviolet rays (wavelength: 365 nm, intensity: 200 mW) toward the heat storage layer in an inert gas oven (temperature: 70° C.) replaced with nitrogen. The amount of ultraviolet radiation is set to 3000mJ / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com