Matrix type hole forming machine for PET film of piezoelectric film sensor

A piezoelectric film and sensor technology, applied in the field of sensors, can solve the problems of residue, reduced monitoring performance of piezoelectric film sensors, and uneven outer surface of PET film.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

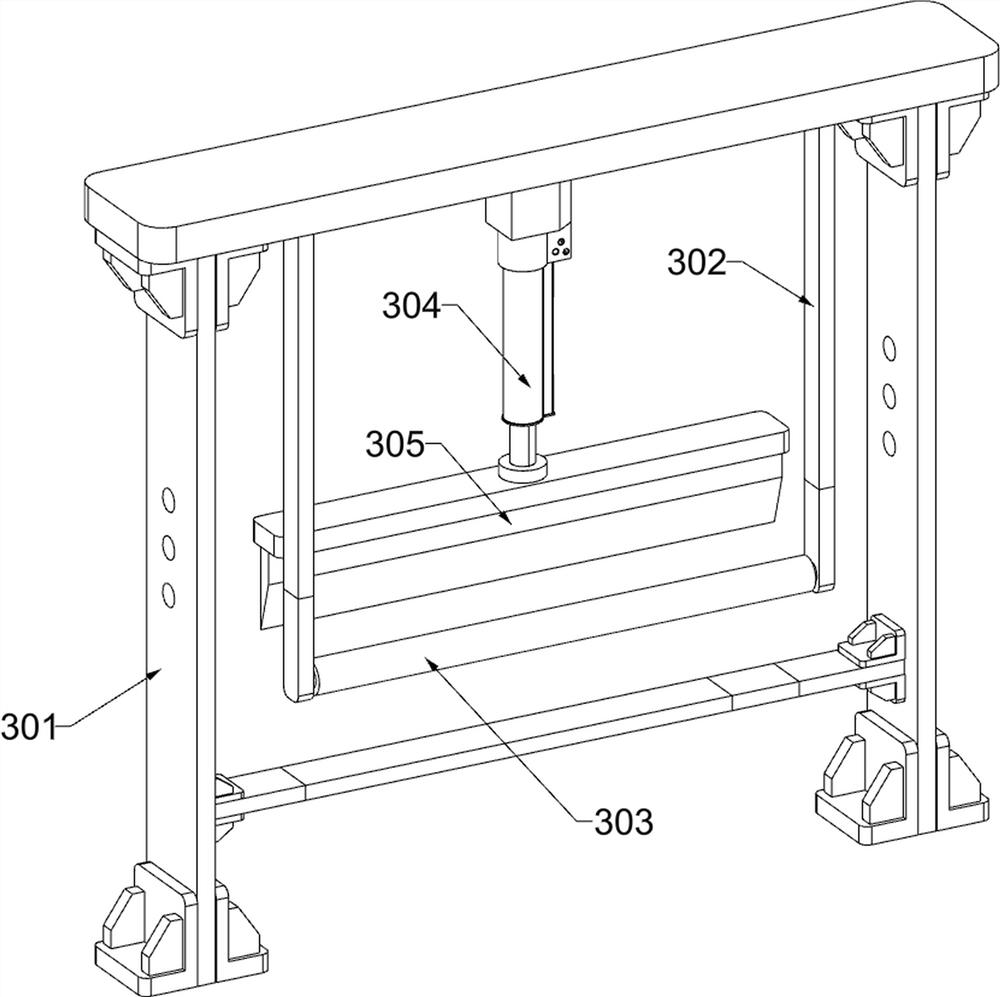

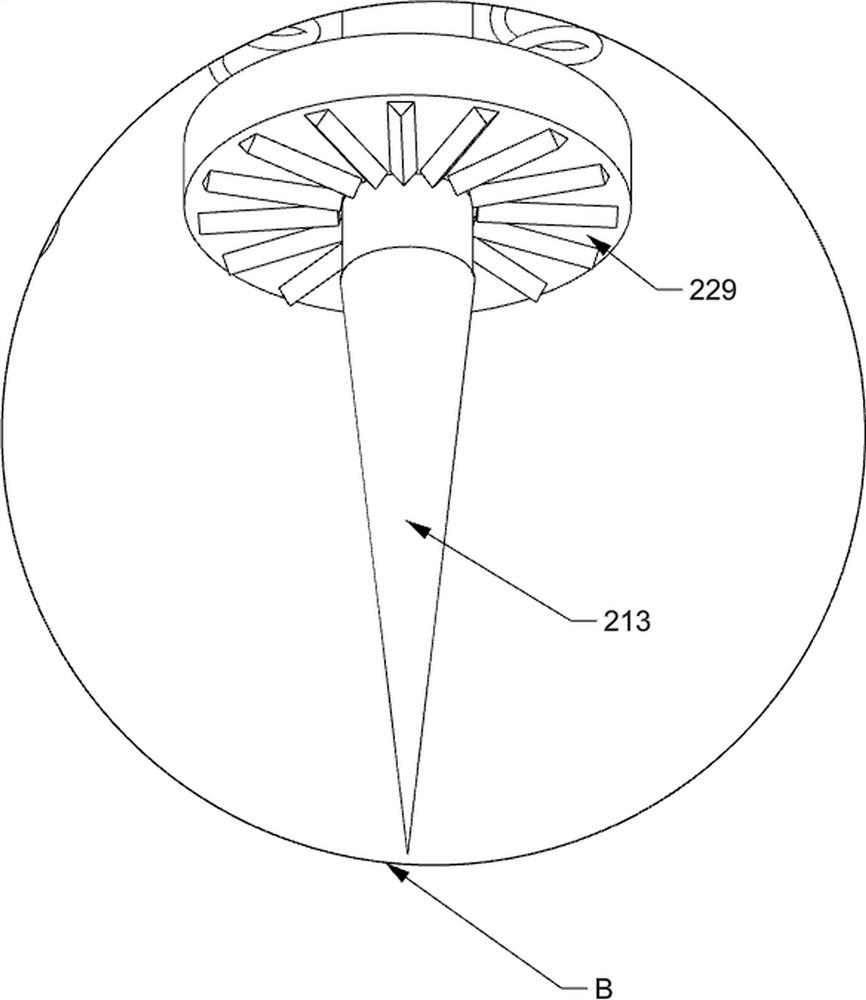

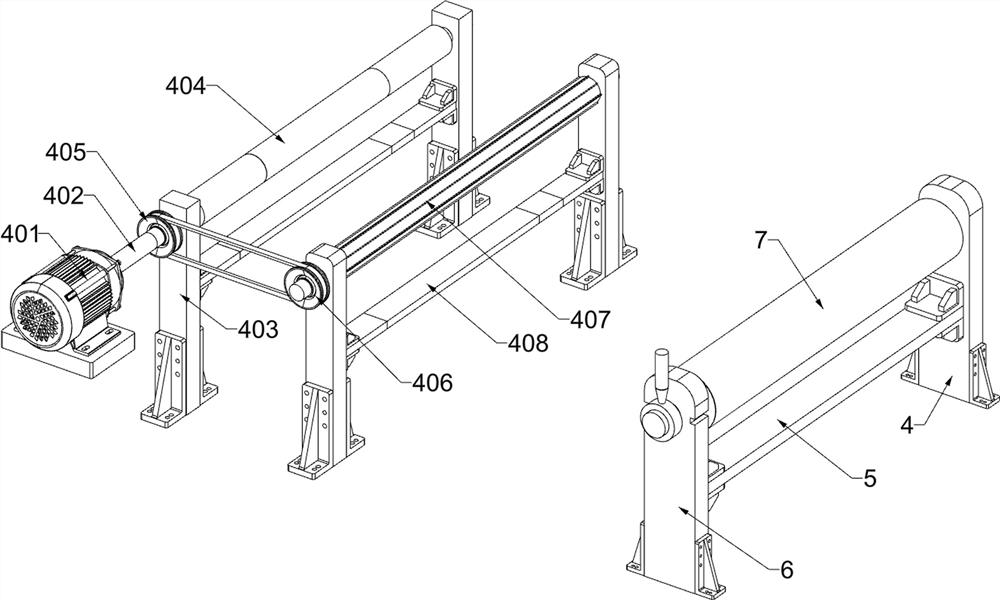

[0029] A piezoelectric film sensor PET film matrix type punching machine, according to Figure 1-3 As shown, it includes a floor assembly 1, a foot 2, an anti-skid pad 3, a first support frame 4, a first support plate 5, a second support frame 6, a first guide wheel 7, a pillar 8, a hole opening unit and a smoothing unit The bottom four corners of the bottom plate assembly 1 are fixedly connected with a leg 2 respectively; the bottom of each leg 2 is fixed with a non-slip pad 3; the upper rear right part of the bottom plate component 1 is fixed with the first support frame 4; the first support The middle part of the front side of the frame 4 is affixed to the first support plate 5; the front end of the first support plate 5 is affixed to the second support frame 6; the lower end of the second support frame 6 is affixed to the bottom plate assembly 1; The rear side of the upper middle part of the second support frame 6 is fixedly connected with the first guide wheel 7; the rear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com