Belt cleaning device for eddy current sorting machine

An eddy current sorting and cleaning device technology, applied in the direction of cleaning devices, conveyors, conveyor objects, etc., can solve the problems of shortening the service life of the conveyor belt, easy condensation, scratching the conveyor belt, etc., to improve the cleanliness of the belt, mutual The effect of good changeability, simplified operation and replacement method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below with reference to the accompanying drawings and examples.

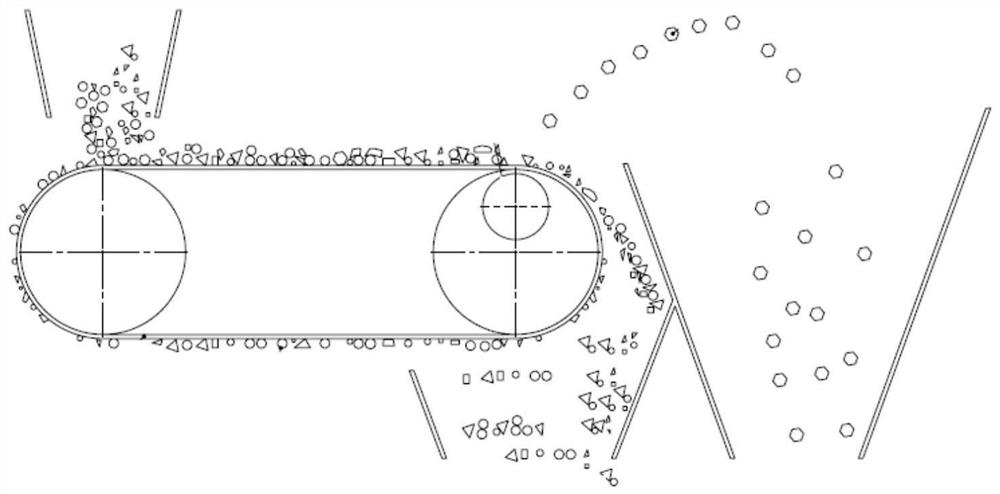

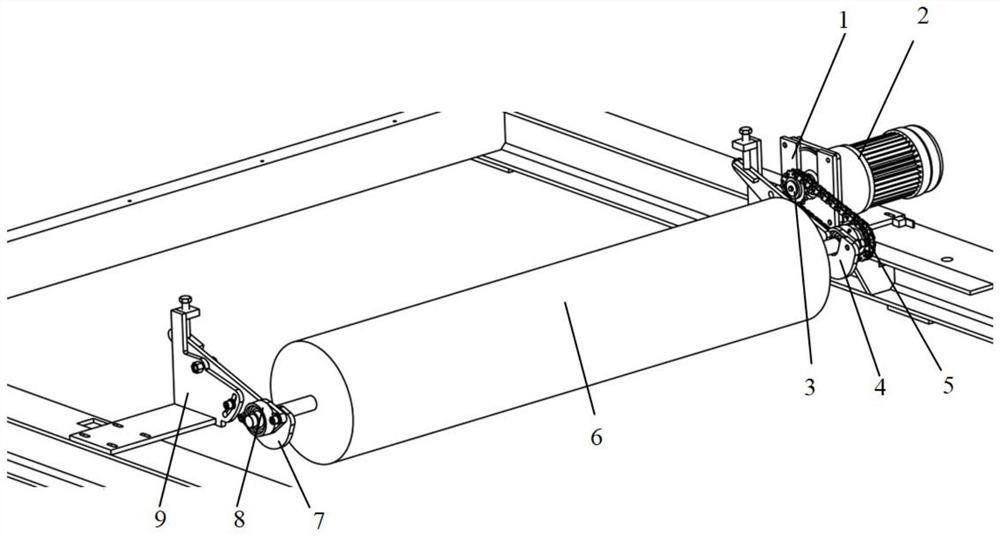

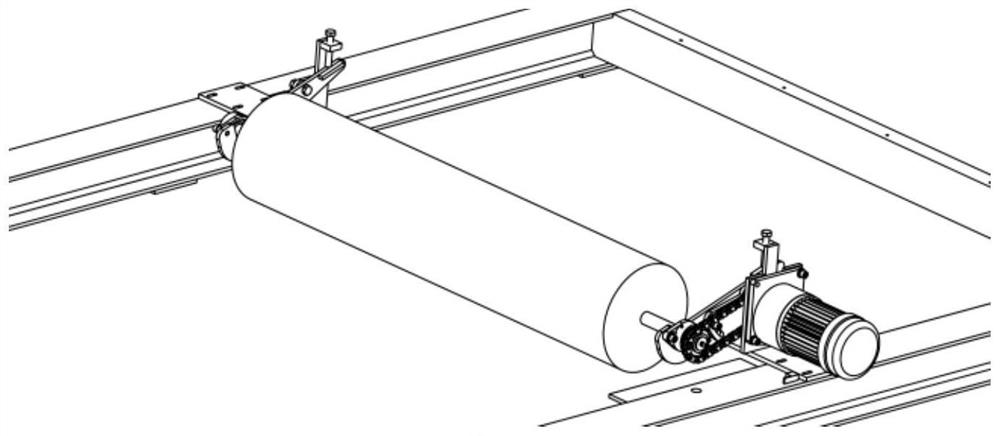

[0041] Such as figure 1 , 2 As shown in and 3, a belt cleaning device for a vortex separator according to the present invention includes an active support assembly 1, a driven support assembly 9, a first arm plate assembly 7, a second arm plate assembly 4, a motor 2, Cleaning roller 6 and transmission mechanism;

[0042]Both the active support assembly 1 and the driven support assembly 9 include a top wire plate 10, an adjustment vertical plate 11 and a motor seat plate 13, and the active support assembly 1 also includes a motor fixing plate 12; as shown in Figure 5(a), the active support assembly In 1, the upper part of one end of the adjustment vertical plate 11 plate surface is fixed with a top wire plate 10, the middle plate surface is processed with a third connecting hole 20, and the other end of the plate surface is processed with an arc long hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com