Recovery device for ultra-high molecular weight polyethylene fiber pre-drawing hot water solvent

A polyethylene fiber and ultra-high molecular weight technology, which is applied in the fields of rayon recycling, fiber chemical characteristics, textiles and papermaking, etc., can solve the problems of inconvenient later operation, relying on a lot of labor, unable to observe the amount of solvent recovery, etc., to achieve easy operation, Effects for later use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

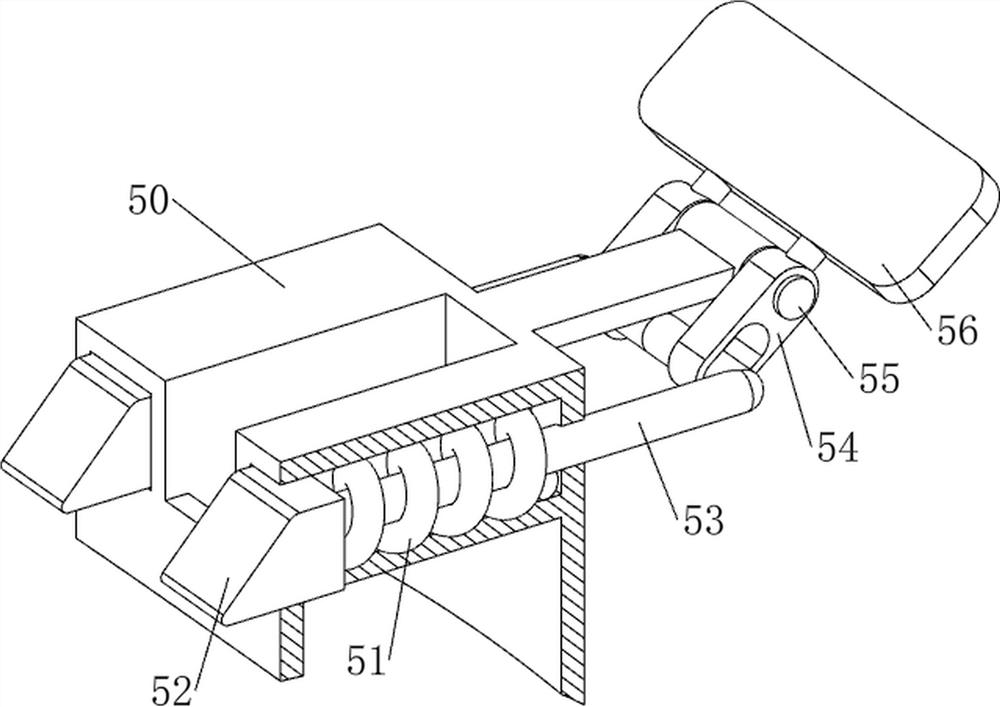

[0035] A recovery device for ultra-high molecular weight polyethylene fiber pre-drawing hot water solvent, such as Figure 1-15 As shown, it includes a casing 1, a material box 2, a pressure mechanism 3 and a display mechanism 4. The top of the casing 1 is provided with a material box 2, the top of the material box 2 is provided with a pressure mechanism 3, and the right side of the material box 2 is provided with a display mechanism 4.

[0036] The pressure mechanism 3 includes a pressing plate 30, a first sliding rod 31, a first spring 32 and a first conduit 33. The top of the material box 2 is symmetrically provided with a first sliding rod 31, and the first sliding rod 31 is slidably connected with a pressing plate. 30 , a first spring 32 is connected between the bottom of the pressing plate 30 and the first sliding rod 31 , and a first conduit 33 is arranged in the pressing plate 30 .

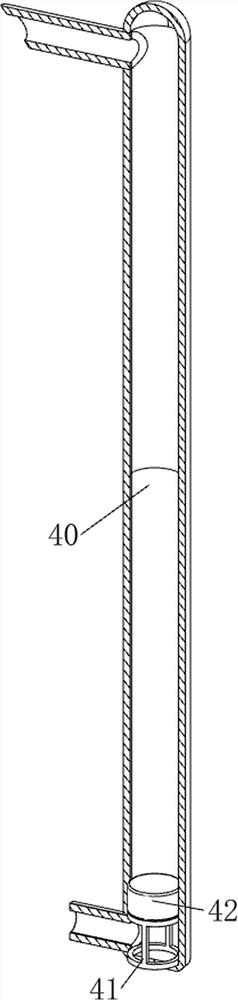

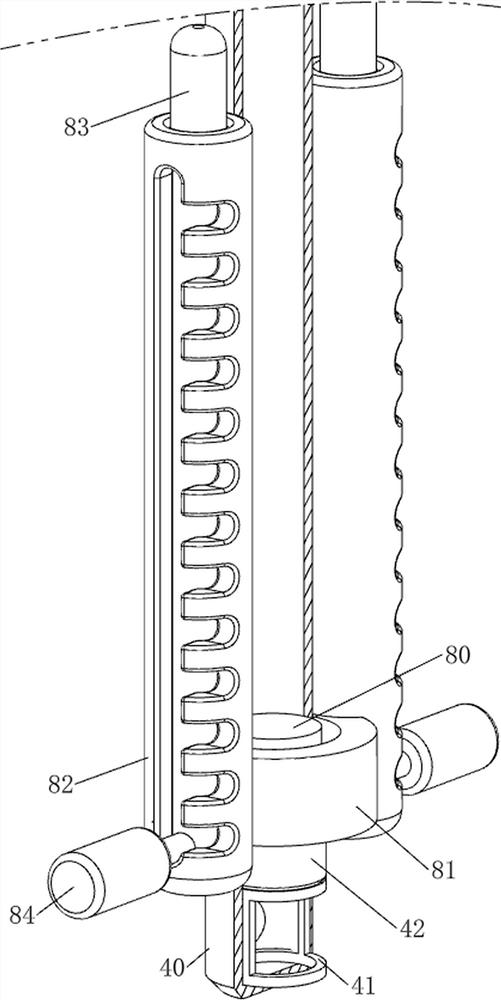

[0037] The display mechanism 4 includes a glass hollow tube 40, a support frame 41 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com