Overhanging type stereo garage

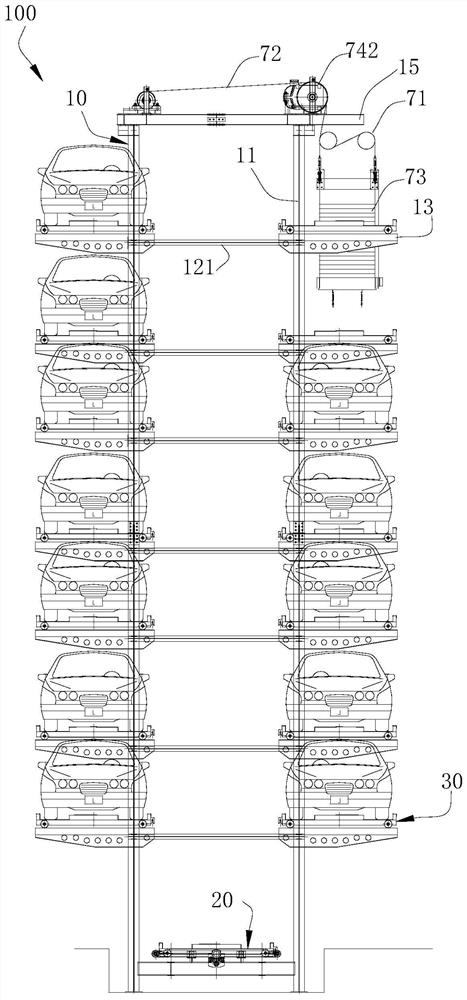

A three-dimensional garage and cantilevered technology, which is applied to buildings, building types, buildings, etc. where cars are parked, can solve problems such as waste of driving energy and complex structures, and achieve the effects of reducing unit costs, simplifying structures, and saving driving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

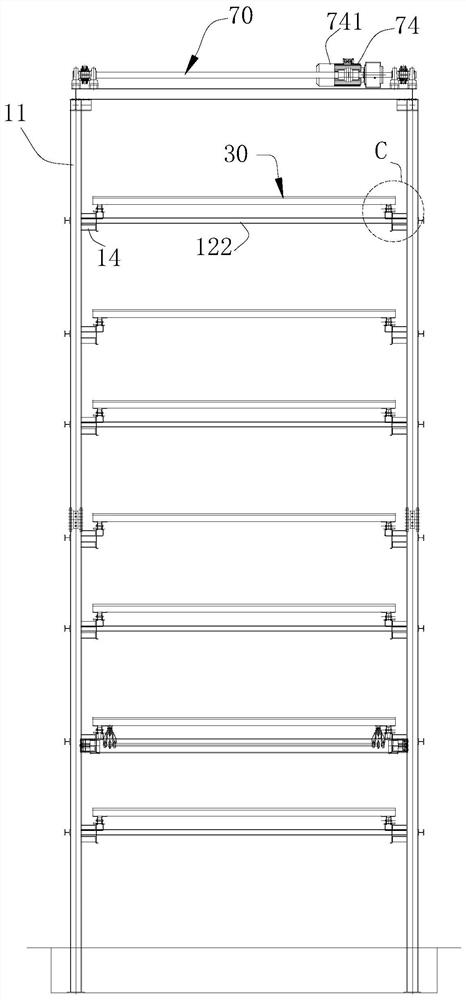

Embodiment 1

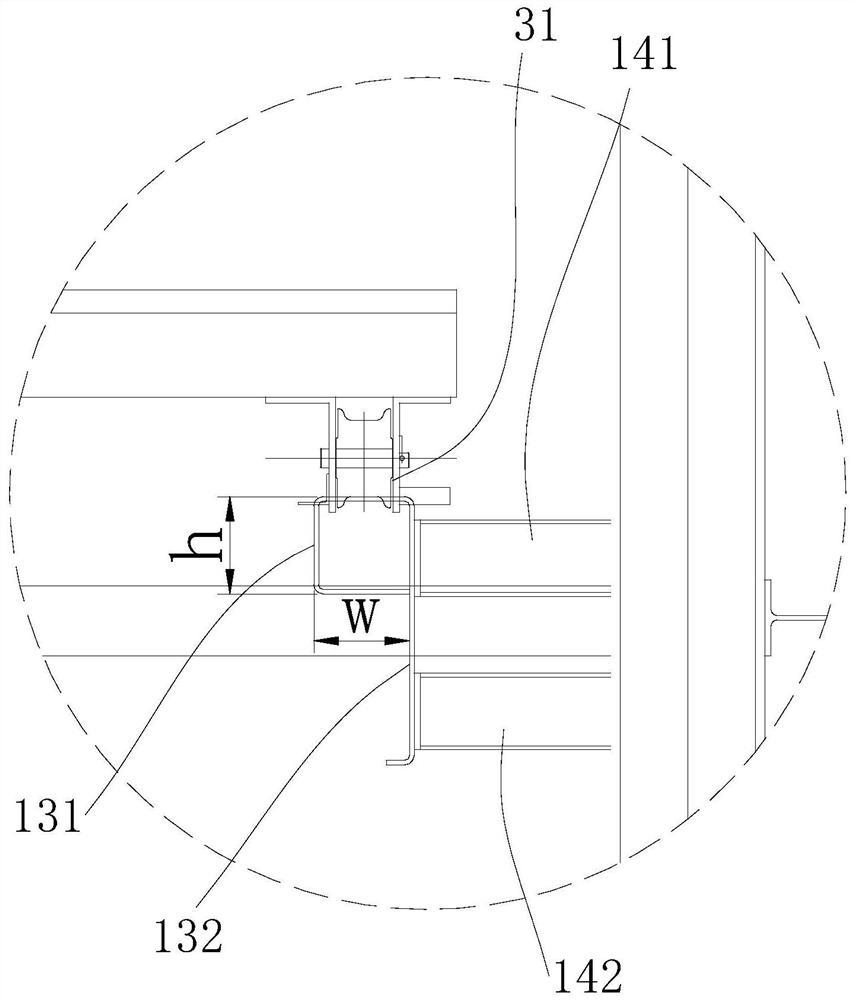

[0053] See Figure 4 and Figure 7 The cross-section of the first part 131 is square or roughly square, the second part 132 is plate-shaped, the first part 131 and the second part 132 are formed by bending steel plates integrally, the side of the first part 131 close to the column 11 and the second part The sides of the second part 132 close to the column 11 are on the same plane. During the bending process, due to technical reasons, the first part 131 opens toward the side of the second part 132 and is not closed.

[0054] A sealing plate 133 is welded at the opening of the first part 131 towards the second part 132 to enhance the bending and torsion resistance of the vehicle panel beam 13 . The thickness of the steel plate used for bending to form the first part 131 and the second part 132 is 3mm-8mm, so as to ensure the rigidity of the vehicle panel beam 13, and can resist the end bending moment of the vehicle panel beam 13 to the greatest extent when it is stressed and ...

Embodiment 2

[0058] See image 3 and Figure 7 , the cross section of the first part 131 is square or roughly square, and is directly formed by a profile; the second part 132 is plate-shaped, formed by a steel plate; Limitally resist the end bending moment and inward torque generated by the vehicle plate beam 13 after being stressed.

[0059] The second part 132 is provided with a plurality of reinforcing ribs 134 spaced from each other, one side of the plurality of reinforcing ribs 134 is connected to the second part 132, and the other side is connected to the bottom surface of the first part 131, which can strengthen the rigidity of the vehicle panel beam 13 and strength. The cross section of the reinforcing rib 134 may be rectangular, triangular or trapezoidal.

[0060] One side of the first girder 141 is connected to the second portion 132 , and the other side is connected to the column 11 . One side of the second girder 142 is similarly connected to the second portion 132 , and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com