Automobile suspension lateral force spring full-stroke motion body outer diameter detection device and method

A technology of automobile suspension and detection device, which is applied in the direction of measuring device, mechanical measuring device, adopting mechanical device, etc., which can solve the problems of harsh requirements, high price and difficult maintenance in the use place, and achieve easy maintenance and efficient outer diameter size , The effect of speeding up the development progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art are in the range of the present invention without making creative labor premise.

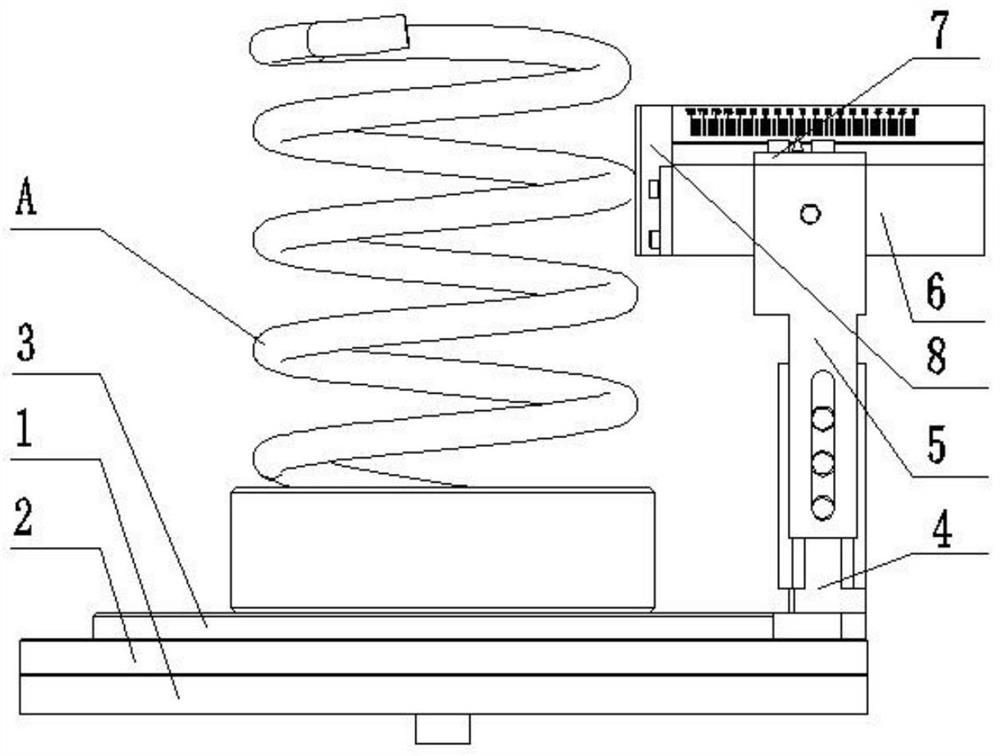

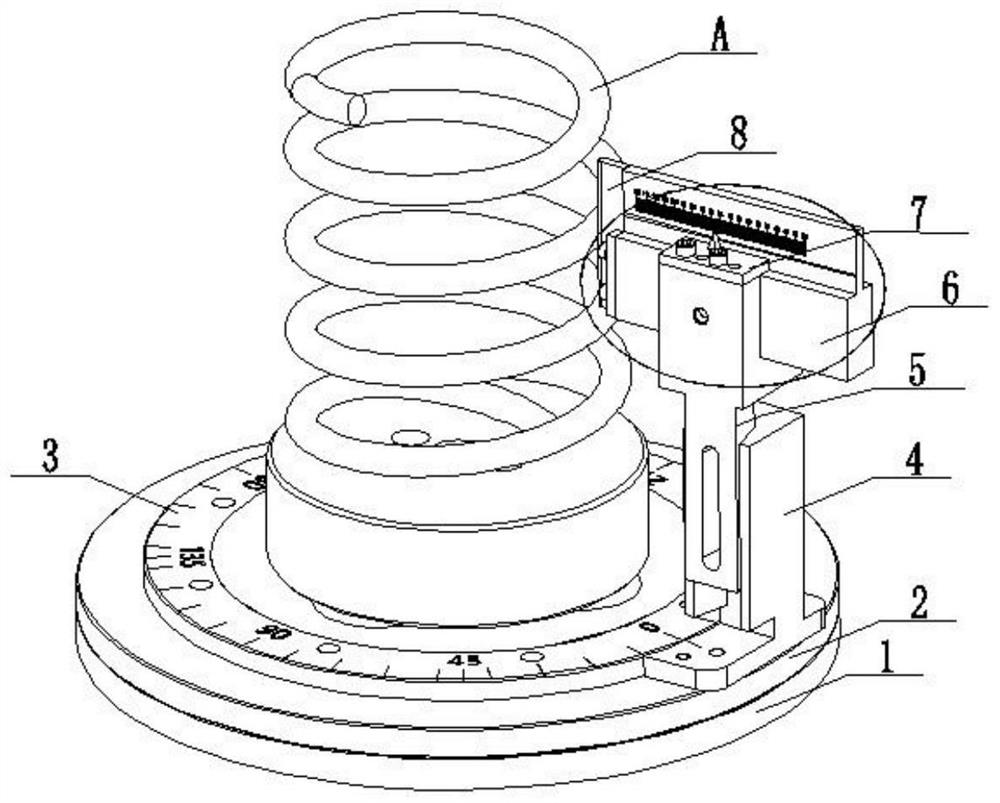

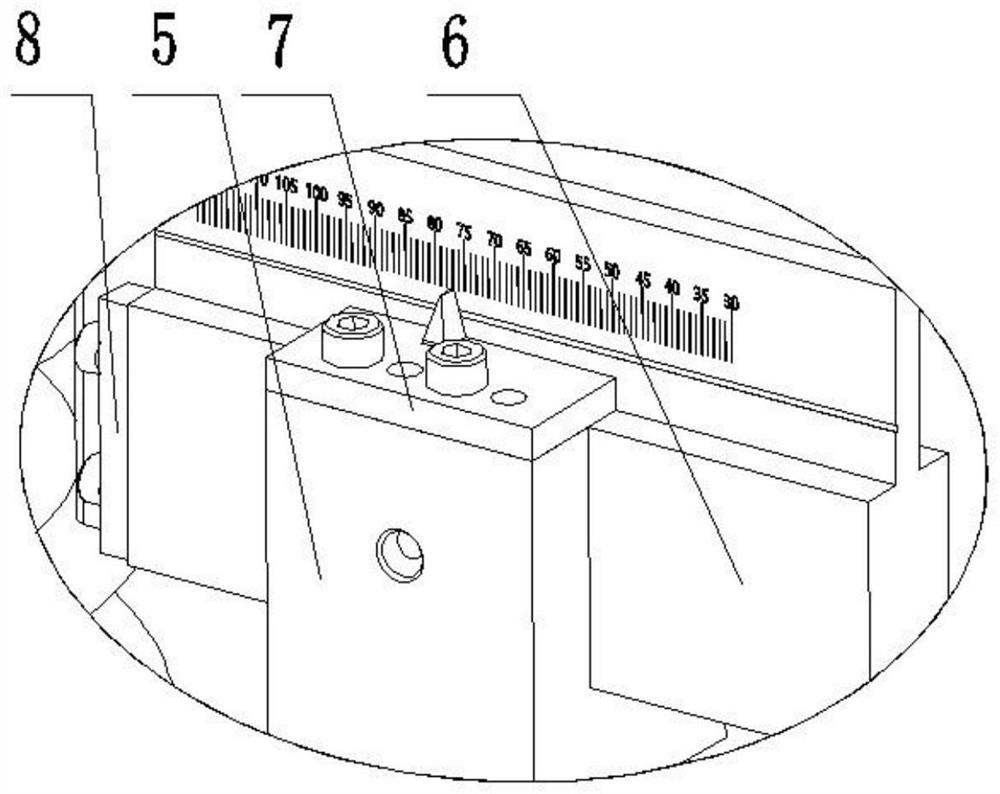

[0039] See Figure 1-17The present invention provides a technical solution: an automobile suspension lateral force spring full stroke moving body outer diameter detecting device, including a circular bottom plate 1, an annular gasket 2, an angle meter 3, a bottom support block 4, top support block 5 , The diameter scale 6, the ruler limit block 7, and the detection end 8, the annular gasket 2 is concentric with the circular bottom plate 1, and the angle sizing 3 is concentric wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com