On-line prediction method for tension fracture of water cooling wall of boiler

A forecasting method and water-cooled wall technology, applied in forecasting, instrumentation, electrical digital data processing, etc., can solve the problems of inaccurate calculation results, difficult to obtain data, and many calculation formulas, so as to reduce the risk of unplanned downtime of boilers and reduce power generation. Effects of losses and labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

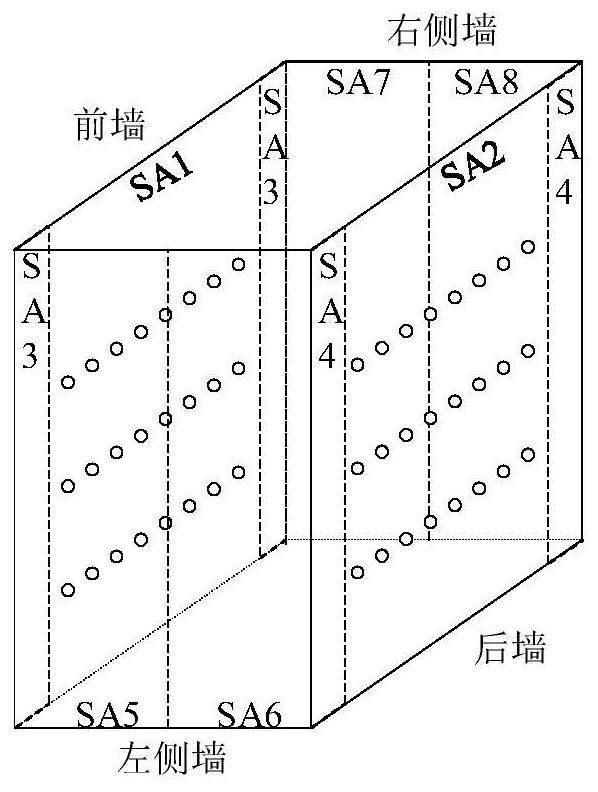

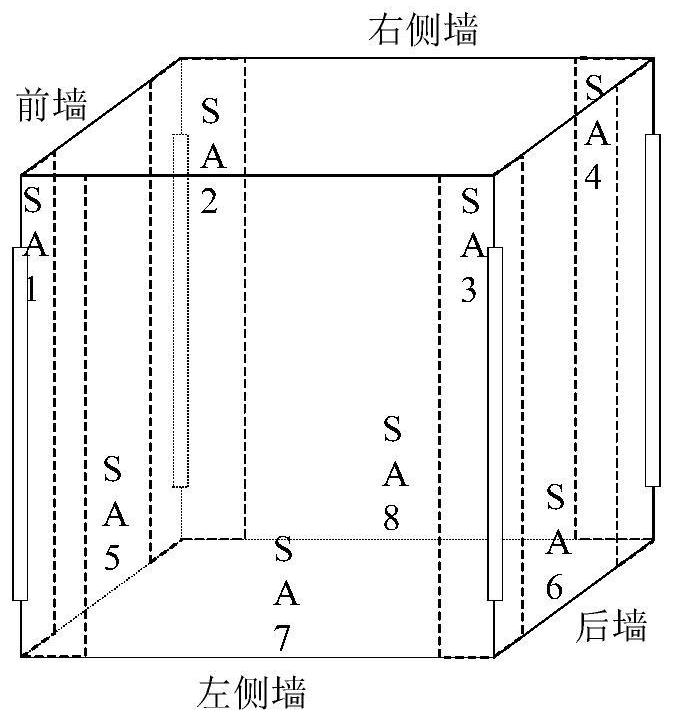

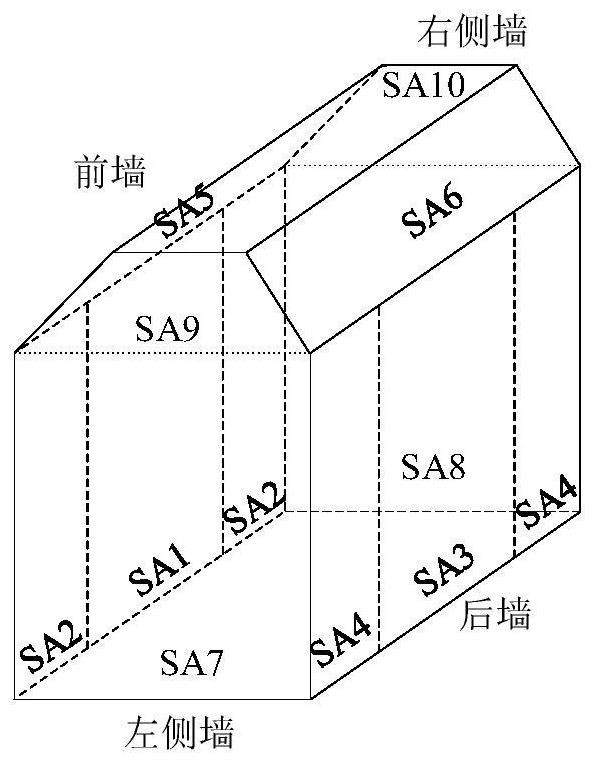

[0072] Such as figure 1 As shown, an online prediction method for boiler water wall cracking includes the following steps:

[0073] Step 1. Divide the water wall into N areas, numbered SA1~SAN;

[0074] Step 2, collect the historical data of the wall temperature of the water-cooled wall, and conduct a preliminary screening of the data;

[0075] Step 3, performing data cleaning on the historical data of the wall temperature of the water-cooled wall obtained in step 2;

[0076] Step 4, extracting the warning database from the wall temperature data obtained in step 3;

[0077] Step 5, constructing the water wall cracking model database;

[0078] Step 6. Construct the learning model of water wall cracking;

[0079] Step 7. Predict whether there is a risk of cracking in the water wall tube.

[0080] Step 1. Divide the water wall into N areas, numbered SA1~SAN;

[0081] The division principle of the area can be divided according to the heat load on the wall and the degree of f...

Embodiment 2

[0120] Now introduce a certain actual working condition:

[0121] Step 1. Divide the water wall into N areas and number them. The boiler of unit 1# in a certain power plant is a counter-firing boiler, and the water wall area of the boiler is divided into figure 1 The method is divided into 8 areas SA1~SA8.

[0122] Step 2, collect the historical data of wall temperature measurement of the water-cooled wall, and perform preliminary screening of the data. Search the operation and maintenance records of a power plant. The latest three water-cooled wall thickness measurement data are April 29, 2021, November 5, 2020, and April 22, 2020. Read the wall temperature data of the water-cooled wall from April 22, 2020 to April 29, 2021 from the SIS system of the power plant. There are 286 measuring point data on the water wall of the power plant, which are divided into 8 groups according to the area division method in step 1. The measuring points in the SA1~SA8 area are 56, 53, 23, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com