Tower crane standard section and anti-corrosion spraying process thereof

A standard section, anti-corrosion technology, applied in the direction of coating, crane, spray device, etc., can solve problems such as troublesome spraying work, and achieve the effect of improving spraying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

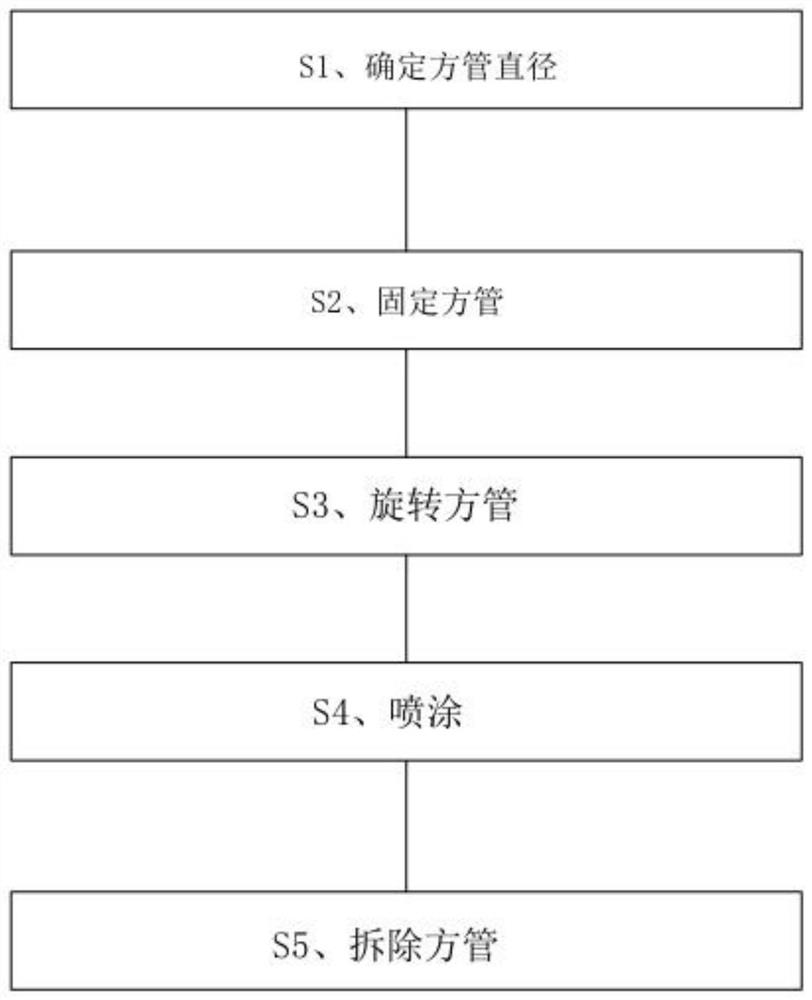

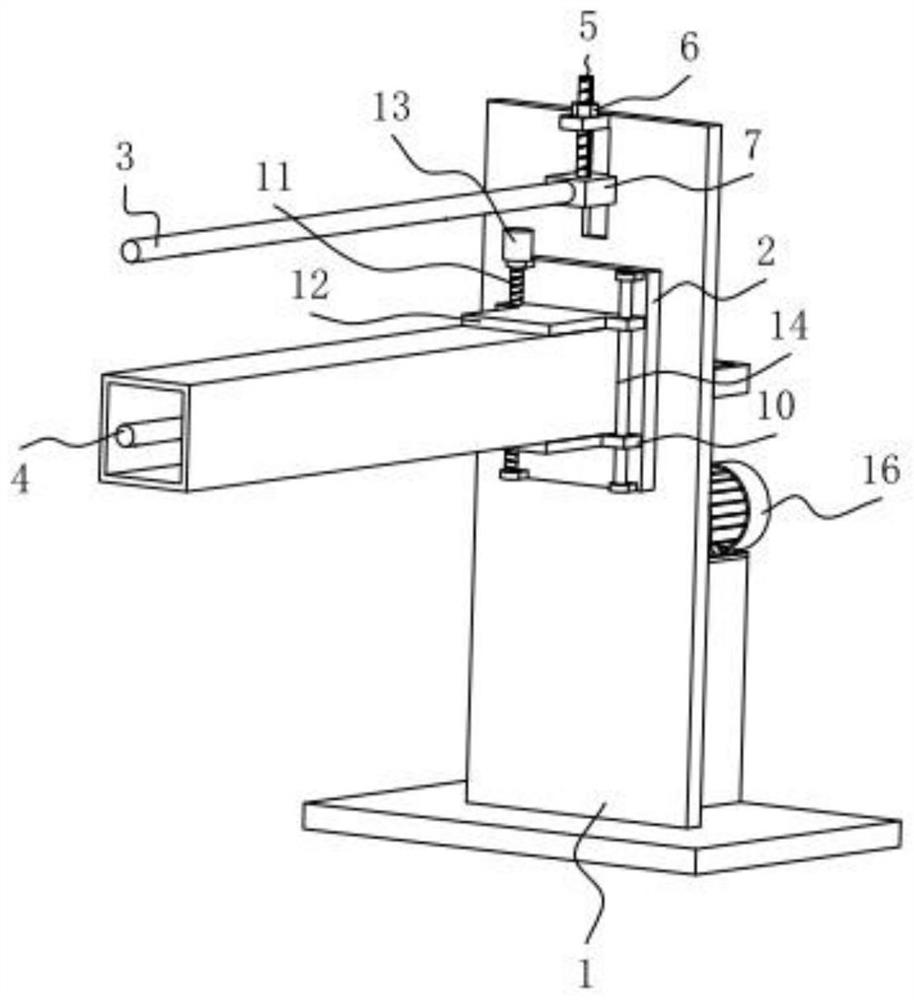

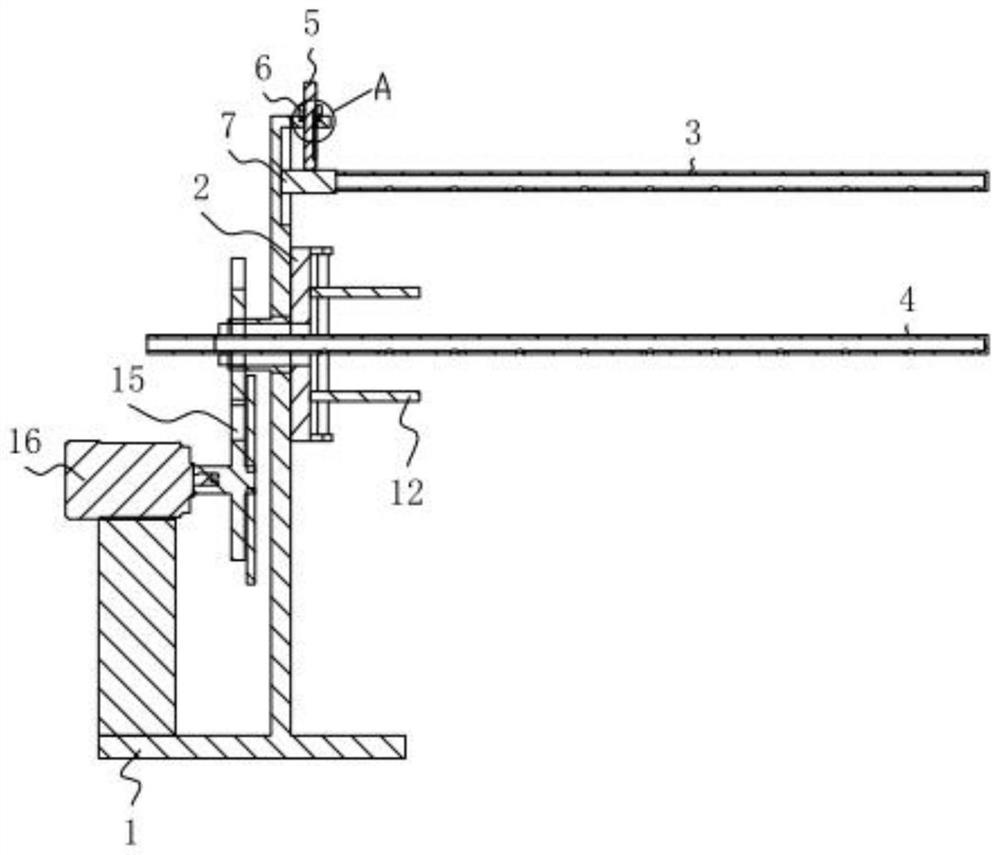

[0044] refer to figure 1 and figure 2 , the embodiment of the present application discloses an anti-corrosion spraying process for the standard section of a tower crane, which includes the following steps,

[0045] S1. Determine the diameter of the square pipe: according to the diameter of the square pipe, control the movement of the outer nozzle 3 on the frame 1 through the adjustment device, adjust the distance between the inner nozzle 4 and the outer nozzle 3, and ensure that the outer nozzle 3 is located above the square pipe Outside; the outer nozzle 3 and the inner nozzle 4 are horizontally arranged, and the peripheral wall is provided with a plurality of nozzle holes distributed along the same horizontal line, and the nozzle holes are arranged downward; the adjustment device includes an adjustment screw 5, which is threaded with the adjustment screw The adjustment nut 6, the adjustment slider 7 and the limit piece, the frame 1 is vertically provided with a through hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com