PE film automatic splitting machine

A dividing machine, automatic technology, applied in the direction of cutting and unsealing, packaging, transportation and packaging, can solve the problems of time-consuming, waste of manpower, etc., and achieve the effect of improving production efficiency, reasonable structure and easy realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

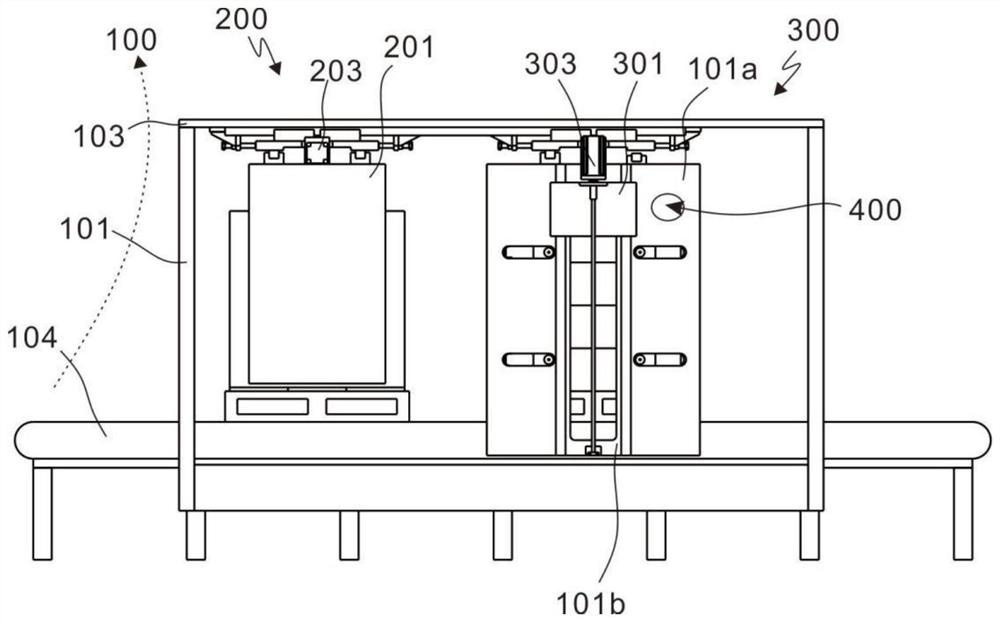

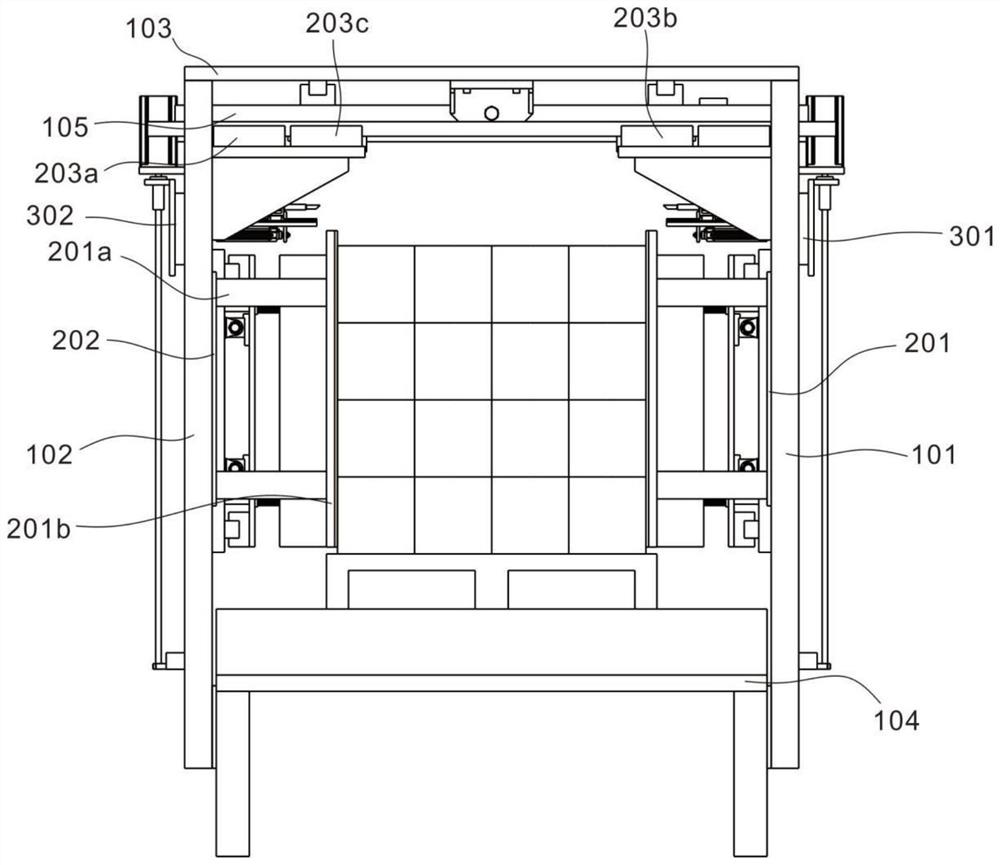

[0030] refer to figure 1 , 2 , is the first embodiment of the present invention, which provides a PE film automatic splitting and dividing machine, including a support module 100 , a sorting module 200 and a cutting module 300 .

[0031] The support module 100 includes a first support frame 101 and a second support frame 102 arranged symmetrically, and a top plate 103 for connecting the first support frame 101 and the second support frame 102, between the first support frame 101 and the second support frame 102 A certain space is formed between the first support frame 101 and the second support frame 102, and a transfer table 104 is arranged between the first support frame 101 and the second support frame 102. The goods are piled on the cargo board and then placed on the transfer table 104. 104, that is, transfer from one end of the support module 100 to the other end of the support module 100.

[0032] When transporting on the conveyor table 104, there are two processes in ...

Embodiment 2

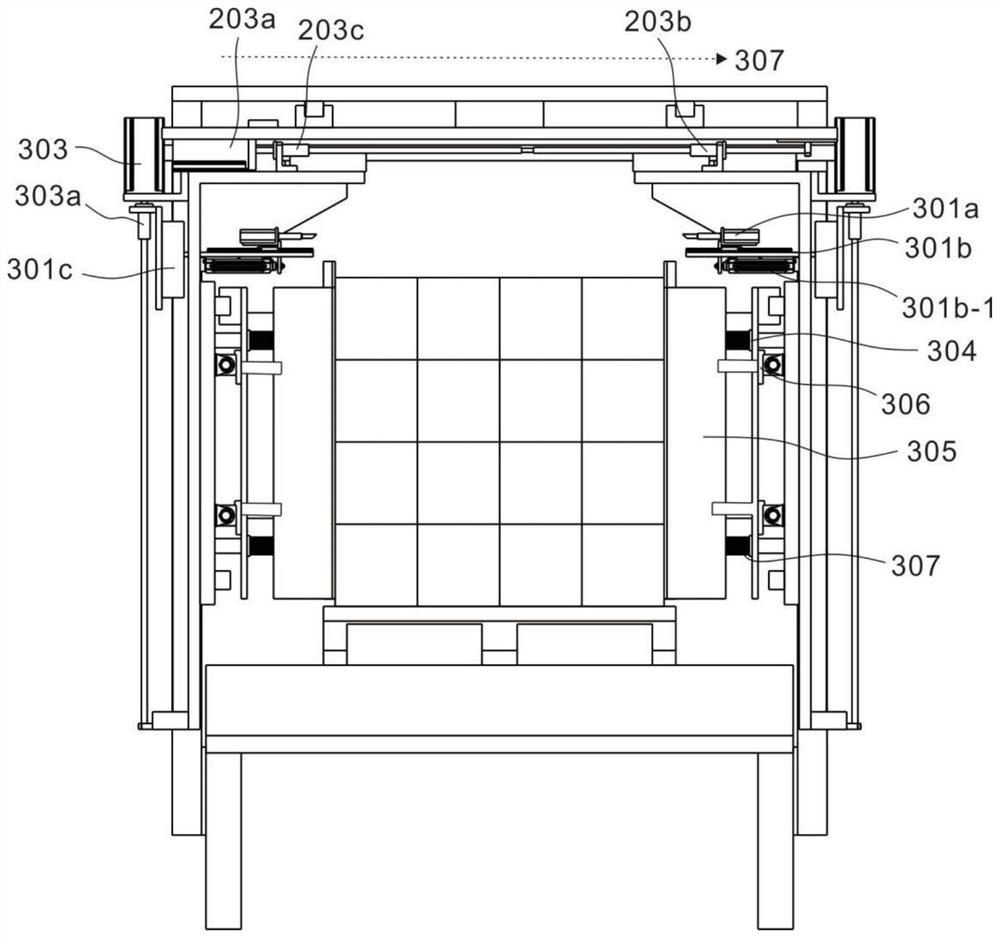

[0039] refer to figure 1 , 3 And 4, is the second embodiment of the present invention, this embodiment is based on the previous embodiment, the first supporting frame 101 and the second supporting frame 102 are all provided with fixed side plate 101a, the first cutting part 301 and the second cutting The member 302 is movably arranged on the fixed side plate 101a.

[0040] The first cutting part 301 and the second cutting part 302 have the same structure, and the first cutting part 301 includes an ultrasonic knife 301a, a bracket 301b and a slider 301c. Specifically, the fixed side plate 101a is provided with a slide rail 101b, the slide block 301c is installed on the slide rail 101b and connected to the bracket 301b, the ultrasonic knife 301a is installed on the bracket 301b, the bottom of the bracket 301b is provided with a first cylinder 301b-1, and the second A cylinder 301b-1 is connected to the ultrasonic scriber 301a. The first cylinder 301b-1 can drive the position o...

Embodiment 3

[0045] refer to Figure 4~7 , is the third embodiment of the present invention, which is based on the previous embodiment, and further includes a locking module 400, the locking module 400 includes two clamping blocks 402 and a manipulation member 403 that are pushed toward a circular plate 401, symmetrically arranged.

[0046] The fixed side plate 101a is provided with vertical slots 101a-2, the number of vertical slots 101a-2 is set to two and the two vertical slots 101a-2 are arranged in the vertical direction, pushed to the circular plate 401 and installed on the fixed side plate 101a to rotate Connection, the center of the push-toward circular plate 401 is connected to the area between the two vertical grooves 101 a - 2 , and the vertical grooves 101 a - 2 are arranged symmetrically with respect to the push-toward circular plate 401 .

[0047] Two straight notches 401a are arranged on the upper circumference of the pushing circular plate 401. The straight notches 401a are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com