Oil separation grit chamber used under hand washing sink

A hand-washing sink, oil-separating sedimentation technology, applied in flocculation/sedimentation water/sewage treatment, grease/oily substance/float removal device, water treatment parameter control, etc. Problems such as observation, precipitation and oil separation effect are not good, and the effect of ensuring the discharge standard is achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

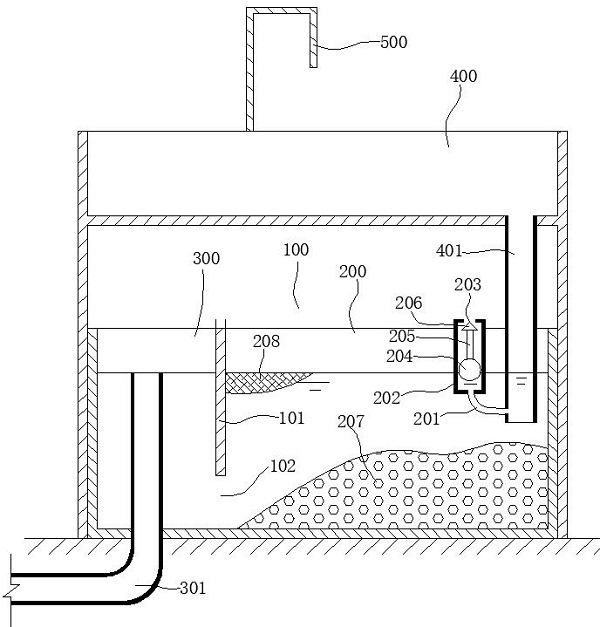

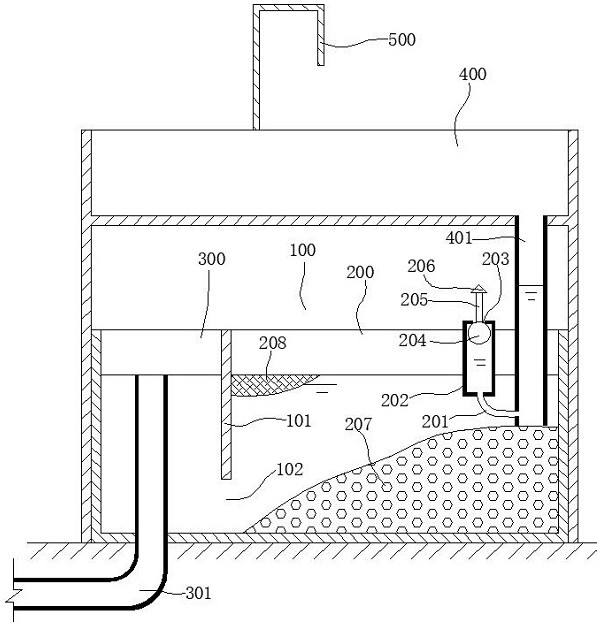

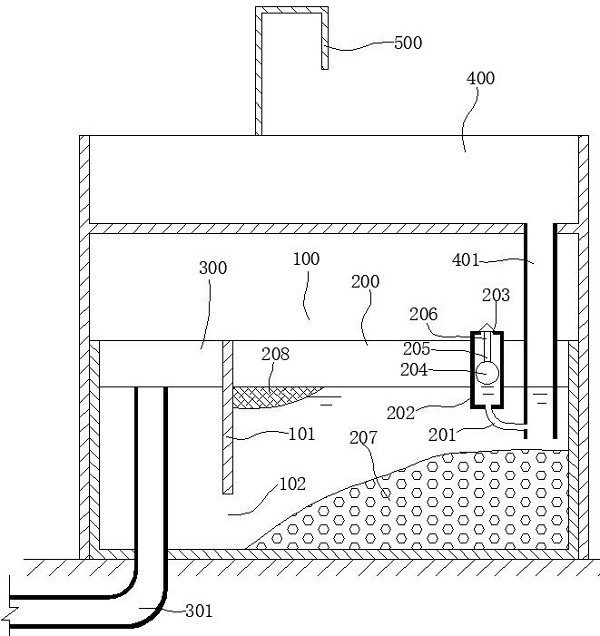

[0010] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 —3.

[0011] An oil separation sedimentation tank used under a hand washing sink, the oil separation sedimentation tank is a box 100 with an open upper end, including a treatment area 200 and a clean water area 300 . A partition 101 is fixedly arranged on the inner walls of the opposite side plates in the box 100 , and a channel 102 is formed between the bottom of the partition 101 and the bottom of the box 100 . The drain pipe 401 outlet of the washbasin 400 is placed at one end of the treatment area 200 of the water tank 100, and the side wall at the outlet of the drain pipe 401 is provided with a connecting pipe 201. The middle part of the cylinder 202 is connected, and the top plate of the cylinder 202 is provided with an opening 203. There is a floating ball 204 inside the cylinder 202. The upper end of the floating ball 204 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com