Unit curtain wall external corner structure with part decoration line

A technology for decorative lines and unit curtain walls, applied in building components, building structures, walls, etc., can solve problems such as hidden dangers of water leakage, hidden dangers of safety, and tearing of glue seams, and achieves convenient design, guaranteeing force stability, and good energy saving. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

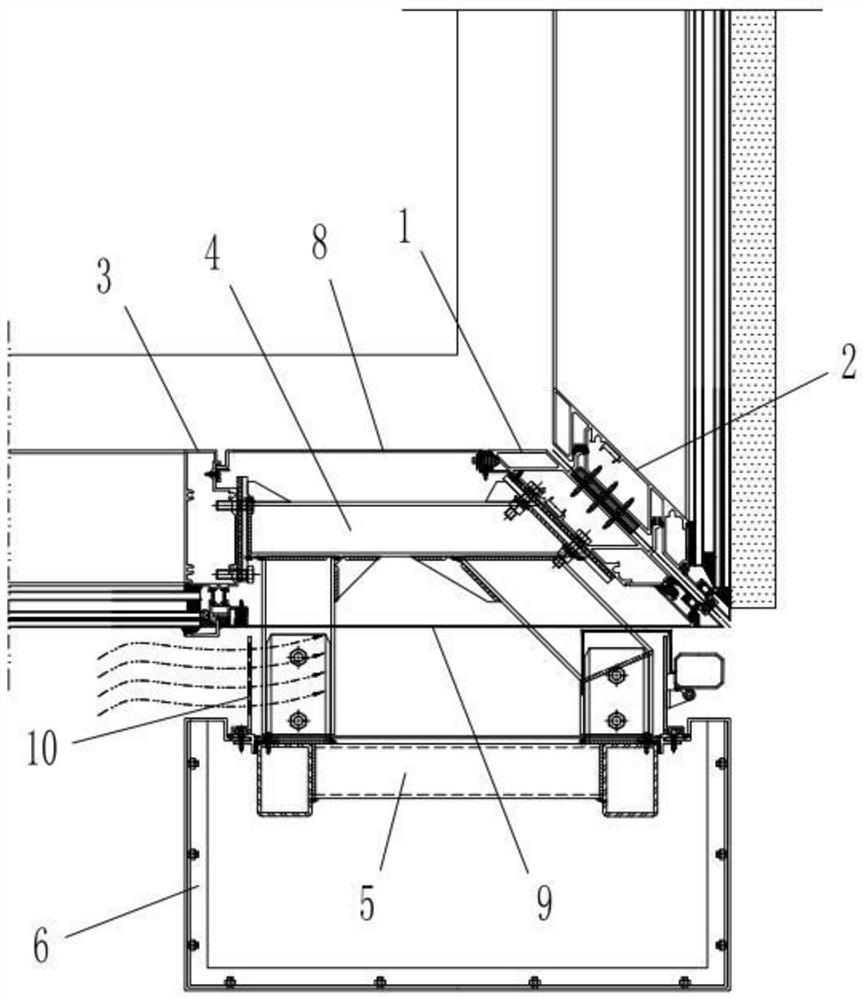

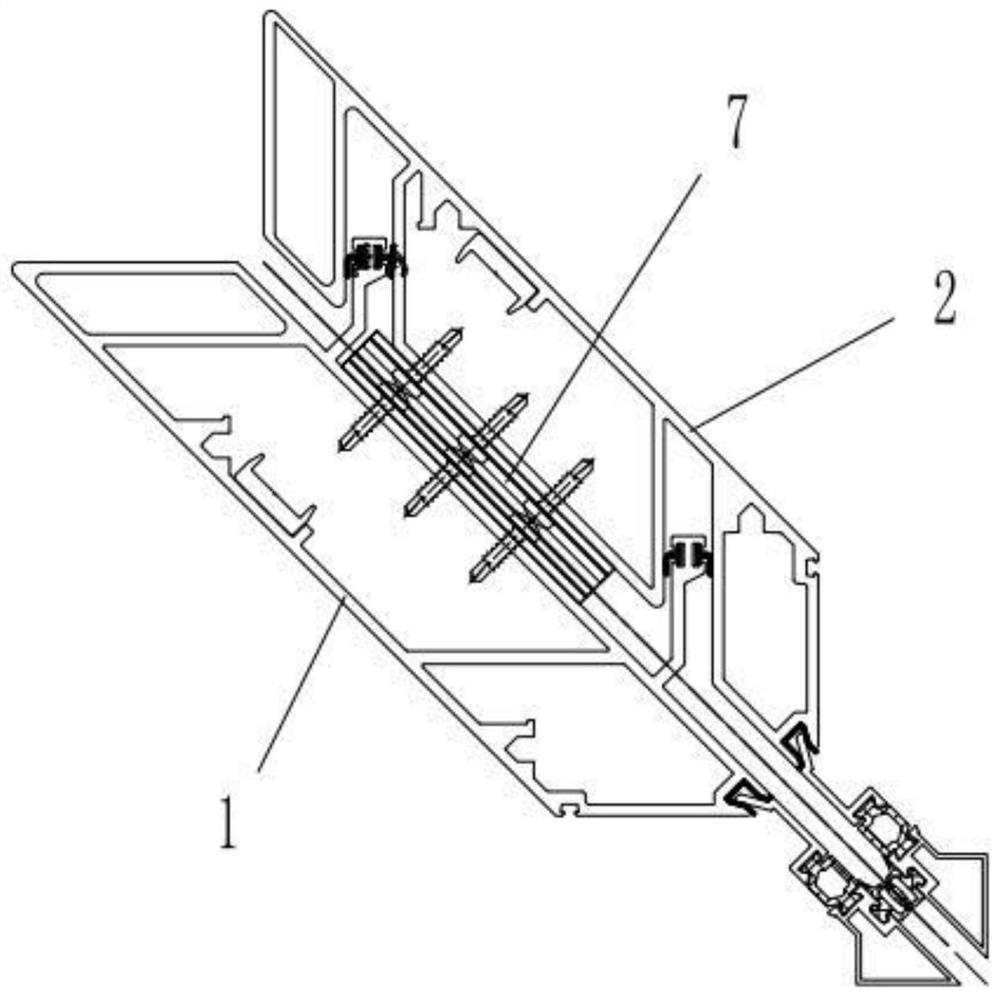

[0018] Such as figure 1 As shown, the male corner structure of a unit curtain wall with component decorative lines according to the present invention includes a public corner column 1, a female corner column 2, a unit column 3, an adapter bracket 4, a line steel frame 5 and a large Decorative moldings6.

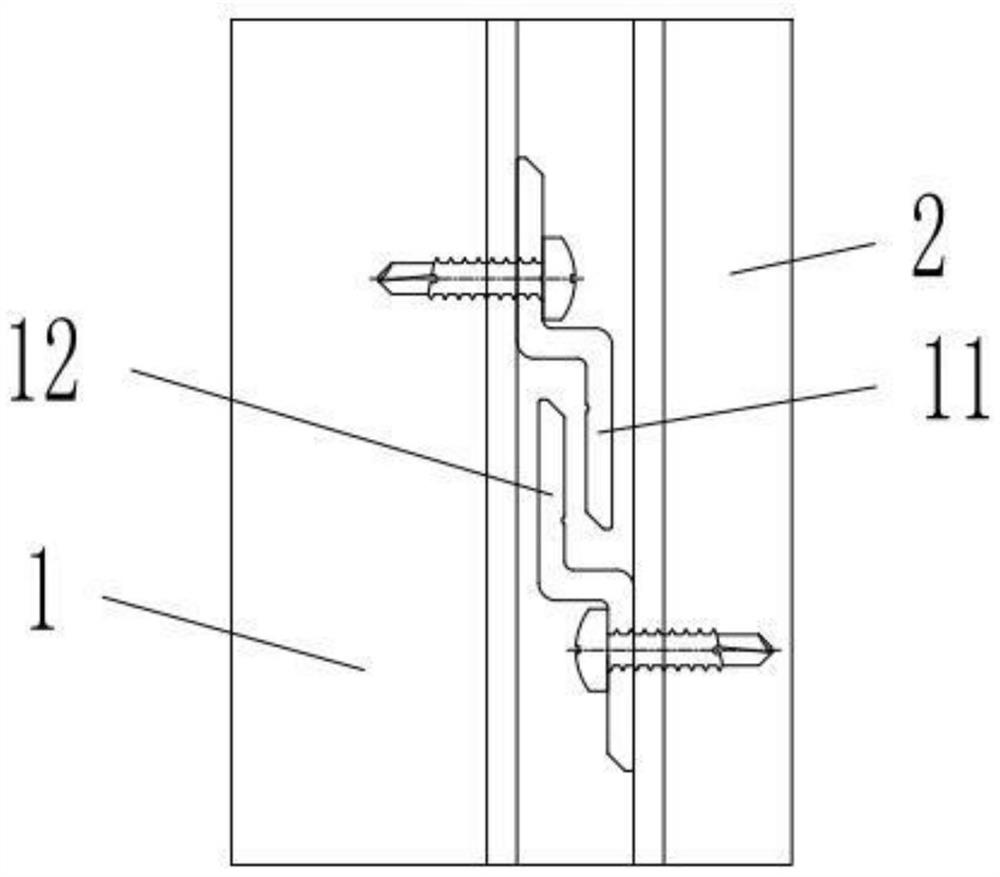

[0019] The public corner column 1 and the female column 2 of the male corner are arranged at the male corner of the building, and the public column 1 of the male corner and the female column 2 of the male corner cooperate with the hook profile assembly 7 and the plug-in structure to form a complete corner column; The hook profile assembly 7 includes an upper hook 11 and a lower hook 12, the upper hook 11 is fixedly installed on the male corner column 1 through a plurality of self-tapping screws, and the lower hook 12 is fixedly inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com