Supersonic porous adsorption type compressor blade with corrugated grooves in suction surface

A porous adsorption and suction surface technology, applied in the field of compressors, can solve the problems of poor suction control of the boundary layer, high shock wave intensity, and severe separation of the boundary layer induced by shock waves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

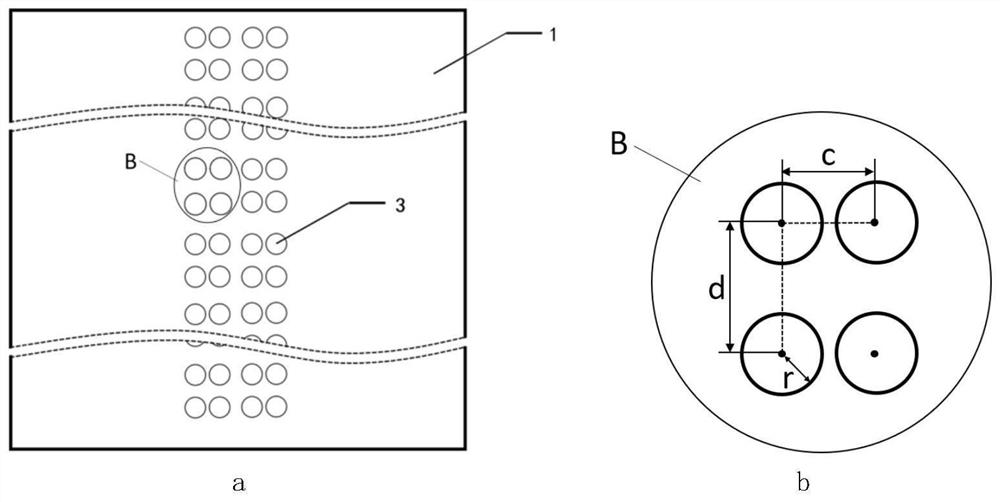

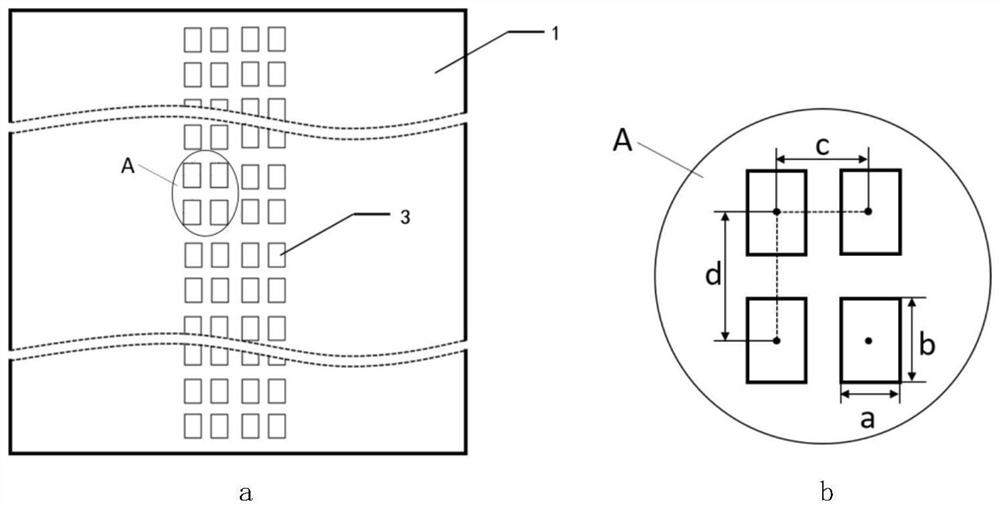

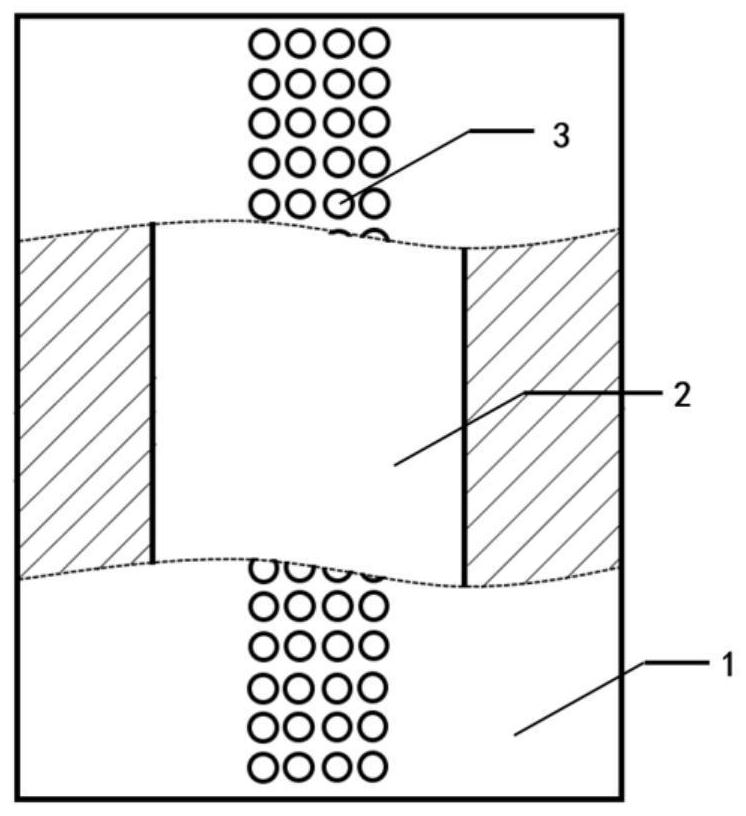

[0036] This embodiment is a supersonic porous adsorption compressor blade with corrugated grooves on the suction surface; the blade is obtained by improving a porous-based supersonic adsorption compressor blade disclosed in CN113153815A.

[0037] The blade shape of the supersonic porous adsorption compressor blade 1 adopts the linear blade shape of the inlet section or the pre-compression blade shape. When a straight airfoil at the inlet section is used, the suction surface of the straight airfoil at the inlet section is a straight line, the straight line is tangent to the arc of the rear section of the suction surface, and the airflow turning angle of the straight section of the blade inlet is 0°. When the pre-compression airfoil is used, the suction surface of the pre-compression airfoil is a smooth curve with a negative angle of the inlet section, and the airfoil line of the front section of the suction is tangent to the airfoil line of the rear section. The maximum thicknes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com