Impingement cooling structure based on array annular protruding target plate

A ring-shaped protrusion and cooling structure technology, which is applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve the problems of dimple structure disturbing wall surface protrusion structure, singleness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0043] This implementation is an impingement cooling structure based on an array of annular convex target plates, including a cold air chamber, impact holes, impact target plates, annular protrusions, and air film holes.

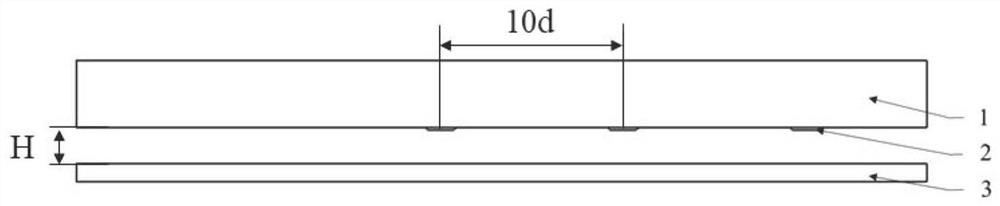

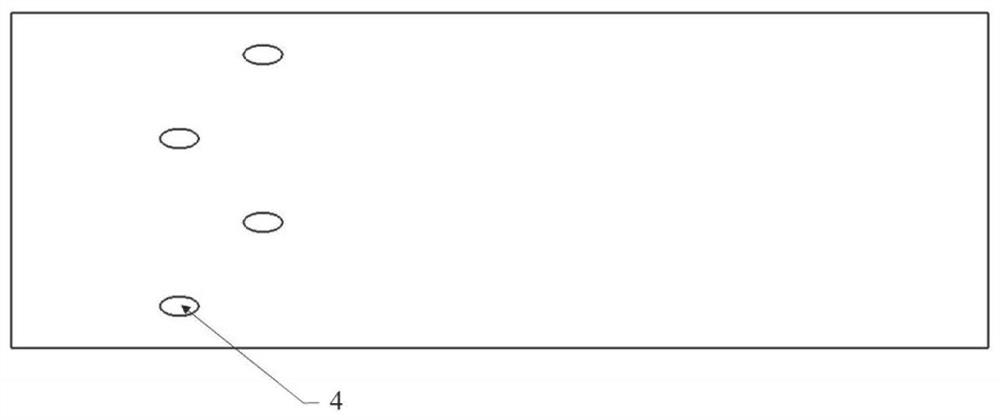

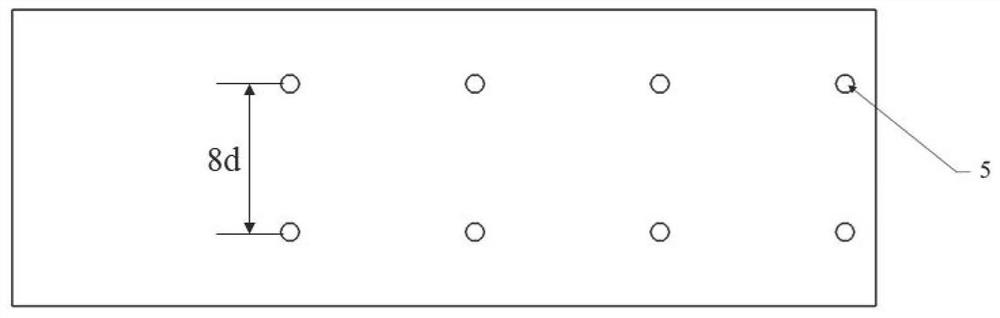

[0044] see figure 1 , the annular protruding structure 2 is located on the impact target plate, the spacing in the span direction is 24 mm, and the spacing in the flow direction is 30 mm. see figure 2 , The gas film hole is located on the side of the impact target plate without the impact hole, the diameter is 2.8mm, the distance between the flow direction and the span direction is 12mm, and the angle between the axis of the gas film hole and the impact target surface is 30°. see image 3 , the diameter of the impact hole is 3mm, the flow direction and the span direction spacing are consistent with the annular protrusion structure, the distance between the first row of impact holes and the center of the nearest air film hole is 28mm, and there is no annu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com