Discharge orifice structure of a cp type single screw pump

A single-screw pump and discharge hole technology, used in pumps, pump components, rotary piston pumps, etc., can solve the problems of inability to transport fluid medium, liquid pressure rise, star gear tooth damage, etc., and achieve low vibration, star gear, etc. The effect of less stress and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

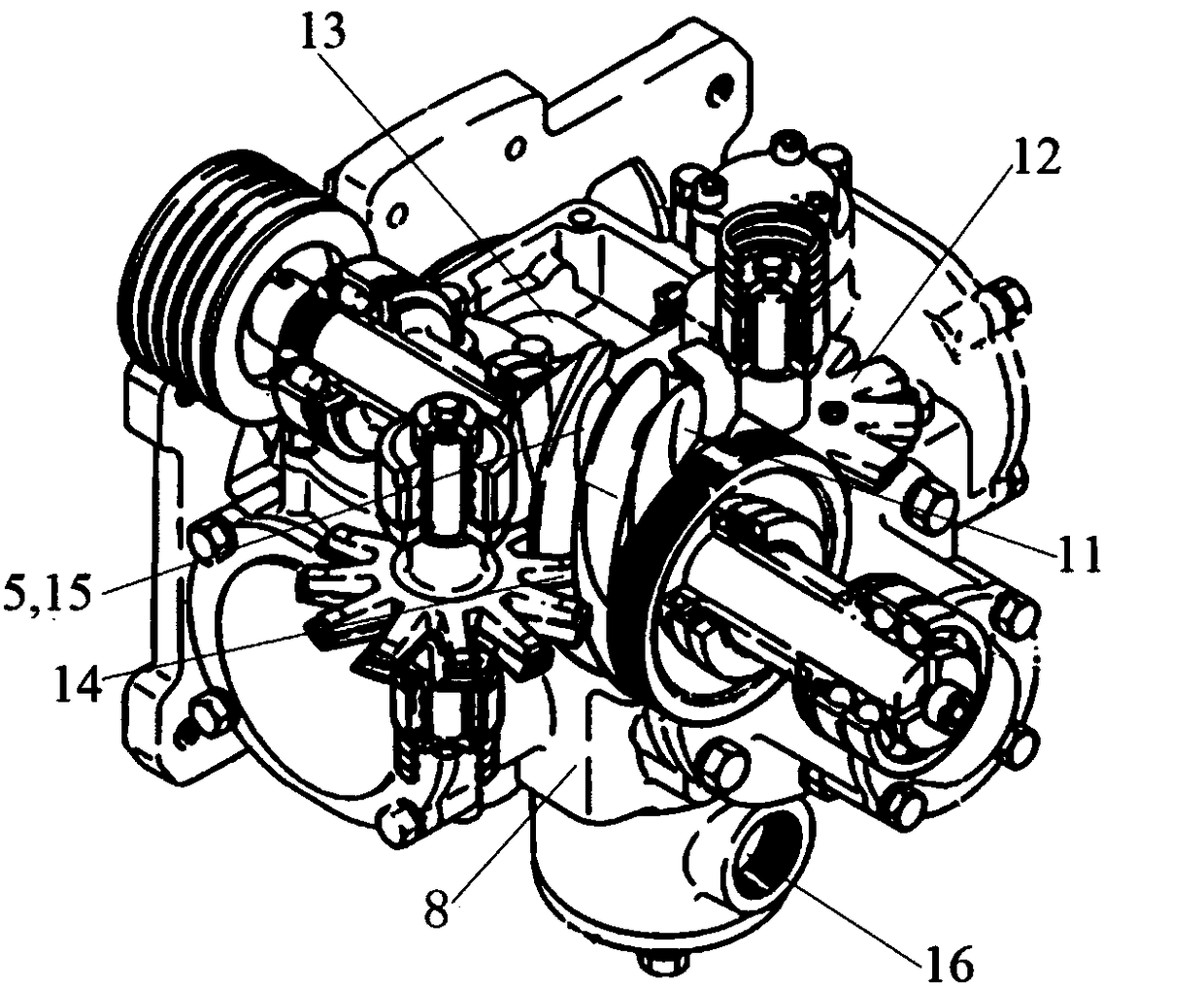

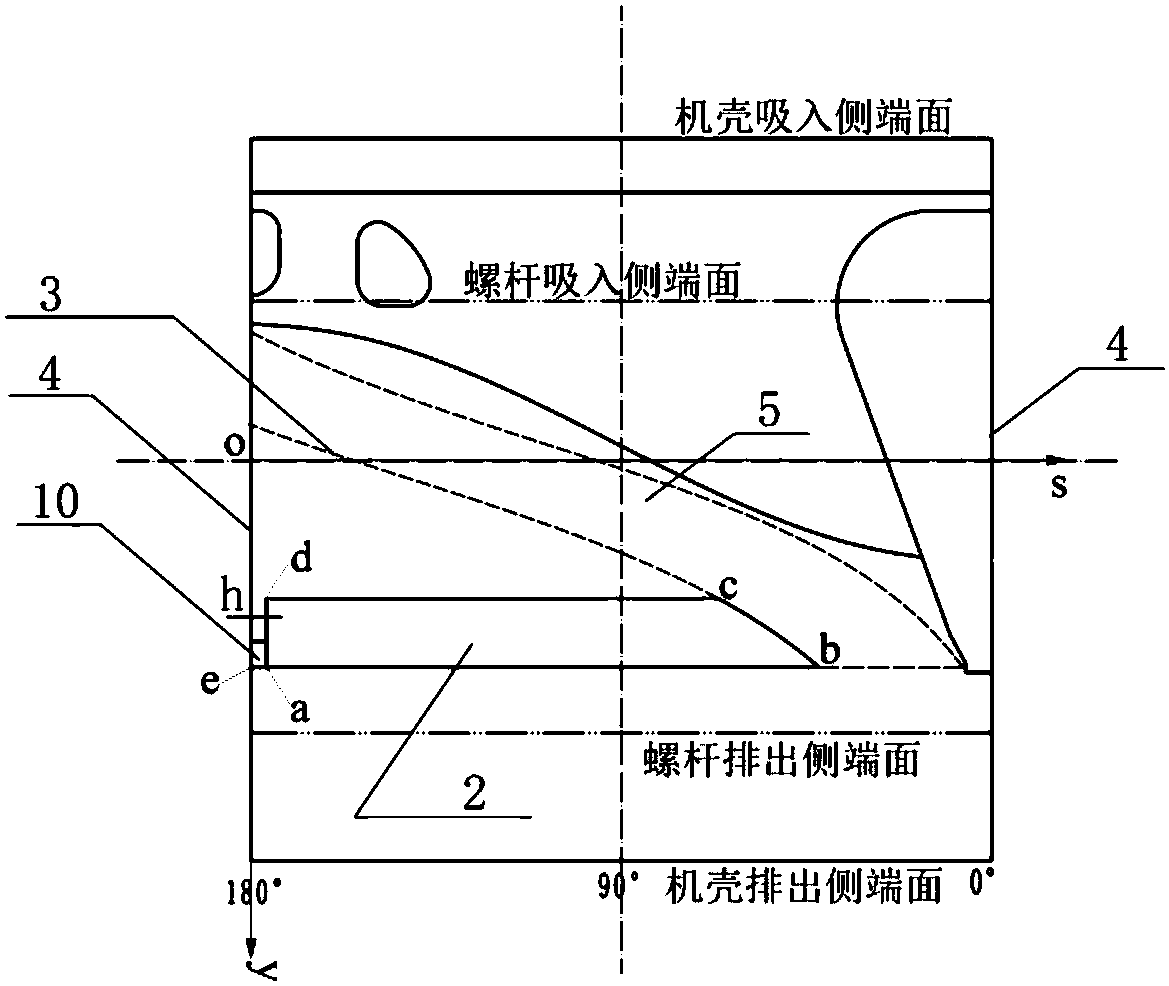

[0048] Embodiment one: for figure 1 For the CP type single-screw pump, when the conveying medium is a single-phase liquid, or a multi-phase medium containing a gas phase is mixed and there is no need to internally compress the gas phase, such as figure 2 The discharge orifice shown. figure 2 It is the expansion diagram of half a cylinder. It can be seen from the diagram that the discharge port is composed of four space curves of ab, bc, cd and da. Point e is the intersection point with the cylinder when the star wheel engages the screw. The ab curve is a part of the arc generated by point e moving along the cylinder surface circumferential direction. The bc curve is a part of the space curve that coincides with the closed helix on the front side of the tooth on the cylinder. The da curve is a straight line close to the neutral plane of the cylinder and the distance from the neutral plane of the cylinder is h. The cd curve is the connecting line between point c and point ...

Embodiment 2

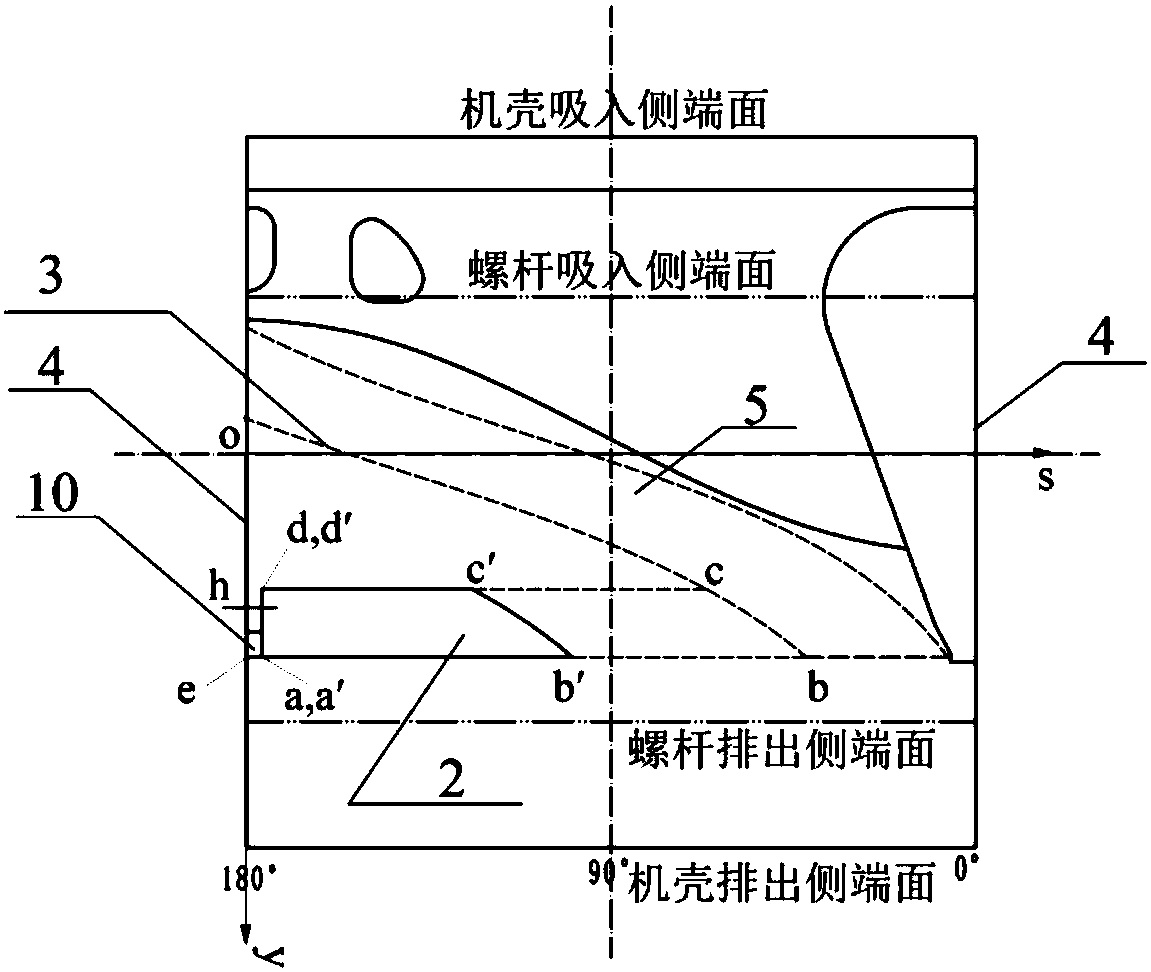

[0052] Embodiment two: for figure 1 For the CP type single screw pump, when the multiphase medium containing the gas phase is mixed and the gas phase needs to be internally compressed to improve the pump efficiency, such as image 3 The discharge orifice shown. image 3 It is an expanded view of half a cylinder. It can be seen from the figure that the discharge port is composed of four space curves a'b', b'c', c'd' and d'a'. Point a' must coincide with point a, curve a'b' must coincide with curve ab and point b' is between point a and point b. The d'a' curve is a straight line close to the cylinder neutral plane 4 and the distance from the cylinder neutral plane is h. The b'c'curve is parallel to the bc curve, and the c'd'curve is the connecting line between point c and point d, which develops into a straight line along the cylinder. established as image 3 The coordinate system shown, the equation for the discharge orifice is obtained:

[0053]

[0054] The coordinate...

Embodiment 3

[0056] Embodiment three: for figure 1 For the CP type single screw pump, when the multiphase medium containing the gas phase is mixed and the gas phase needs to be internally compressed to improve the pump efficiency, such as Figure 4 The discharge orifice shown. Figure 4 It is an expanded view of half a cylinder. As can be seen from the figure, the discharge port is composed of four sections of space curves a "b", b "c", c "d", and d "a". Point a" must coincide with point a, curve a"b" must coincide with curve ab and point b" is between point a and point b. The d"a" curve is a straight line close to the cylinder neutral plane 4 and the distance from the cylinder neutral plane 4 is h. The b "c" curve is parallel to the d"a" curve, and the c"d" curve is the connecting line between the c" point and the d" point, which develops into a straight line along the cylinder. a "b" c "d" is developed into a standard rectangle along the cylinder. established as Figure 4 The coordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com