Method and device for improving tritium value-added rate of fusion reactor

A value-added rate, fusion reactor technology, applied in the field of nuclear fusion, can solve the problems of low load on the sub-wall, inefficient use of precious space at the bottom, and limited space, and achieve the effect of making up for the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The embodiments of the present invention will be further described in detail below in conjunction with the embodiments and drawings, but the embodiments of the present invention are not limited thereto.

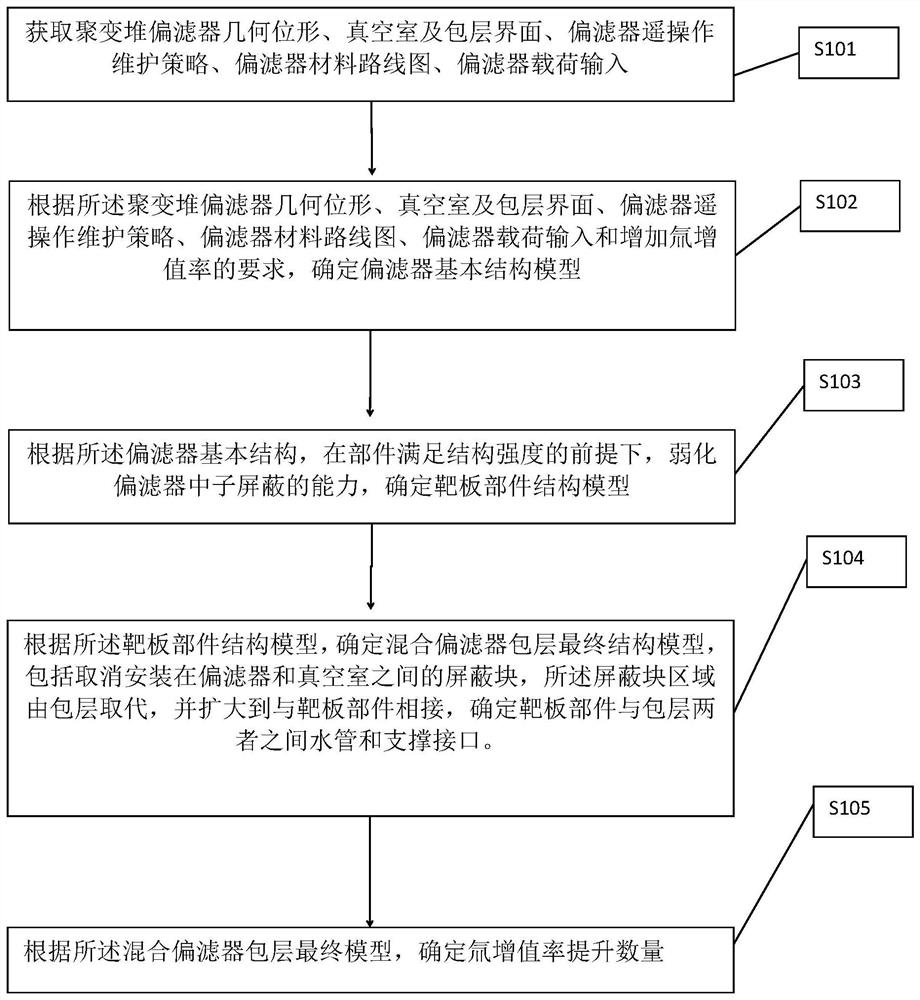

[0033] Embodiments of the present invention provide a method for increasing the value-added rate of fusion reactor tritium, such as figure 1 shown, including the following steps:

[0034] S101: Obtain geometric configuration of the fusion reactor divertor, vacuum chamber and cladding interface, remote operation and maintenance strategy of the divertor, material roadmap of the divertor, and input of the divertor load.

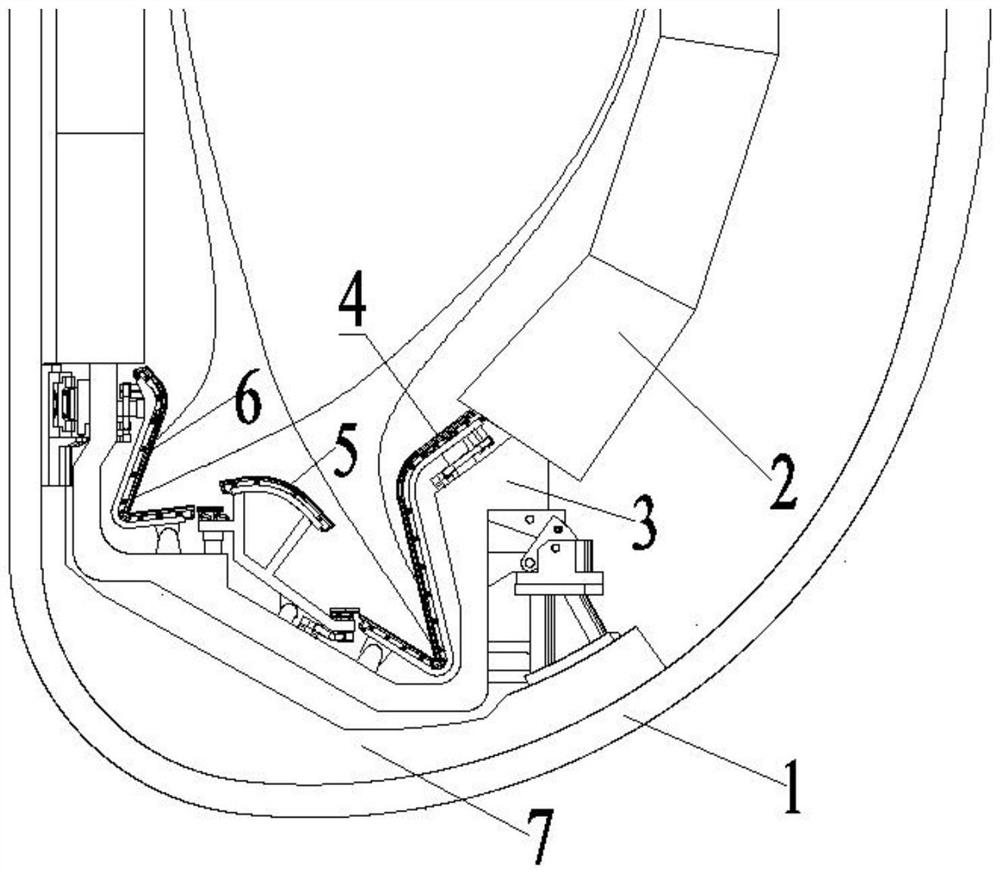

[0035] Such as figure 2 As shown, taking the CFETR design scheme as an example, the geometric configuration of the divertor refers to the geometric boundary of the first wall surface facing the plasma of the outer target plate part 4 of the CFETR scheme, the Dome part 5 of the CFETR scheme and the inner target plate part 6 of the CFETR scheme, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com