Filtering device capable of adjusting fluid temperature

A fluid temperature and filtration device technology, applied in the direction of filtration separation, fixed filter element filter, separation method, etc., can solve the problems of glue slurry physical properties influence, coating scraper impact, influence coating thickness uniformity, etc., to ensure Stable, easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

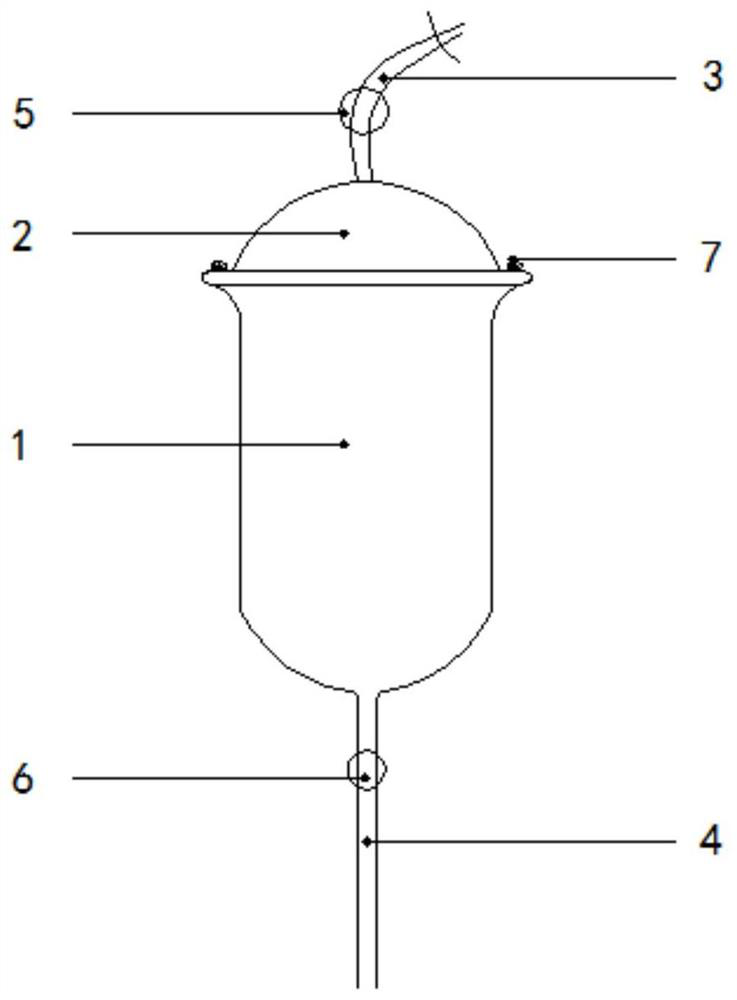

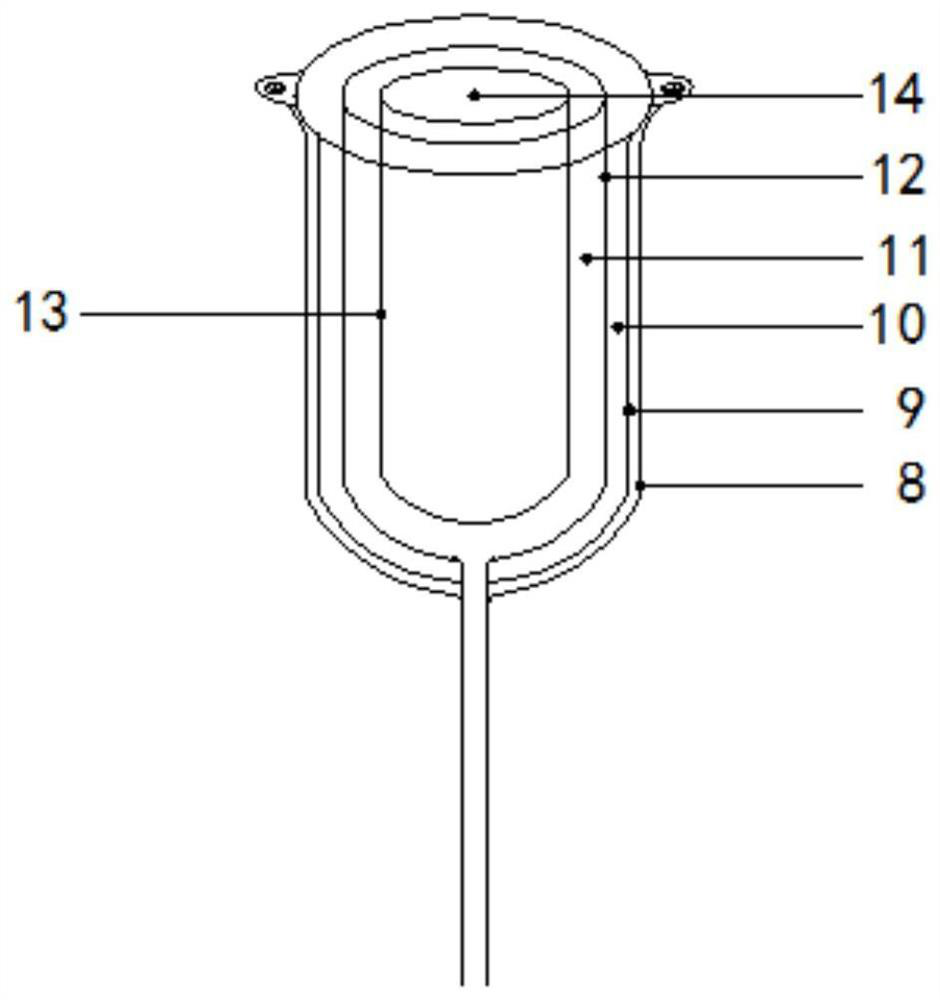

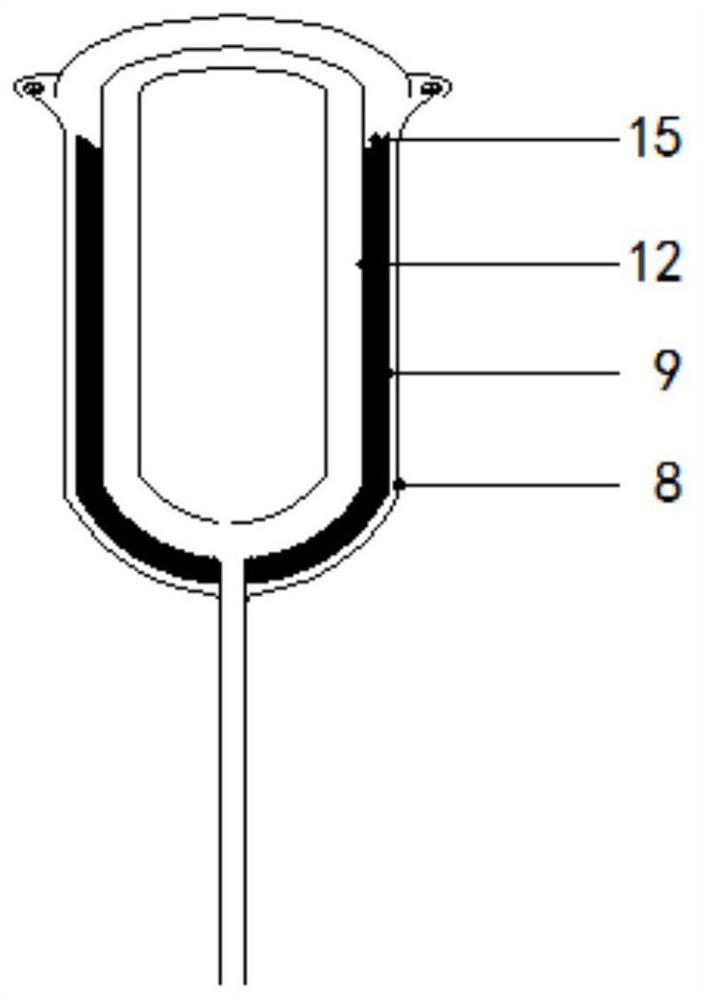

[0024] In one embodiment of the invention, see Figure 1 to Figure 4 , provides a filter device that can adjust the fluid temperature, including a main body 1, a cover 2 located above the main body 1, a feed pipe 3 connected to the cover 2, and an outlet located below the main body 1 The feed pipe 4, the cover body 2 is detachably fixed on the main body 1 through the connecting piece 7, the feed pipe 3 and the discharge pipe 4 are respectively provided with a feed temperature sensor 5 and a discharge pipe Temperature Sensing Table 6. The connecting piece 7 can be a fixed screw or other fixed and detachable connecting devices, and the fluid is transported into the main body 1 through the feed pipe 3, and the fluid is filtered through the main body 1, and the structure is simple and easy to operate.

[0025] Optionally: the main body 1 is a cavity str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com