Continuous sand screening device for constructional engineering

A construction engineering and continuous technology, applied in the direction of filtering, separating solids from solids with air flow, solid separation, etc., can solve the waste of sand, poor separation effect of bonded sand and stones, and affect the economy Benefits and other issues to achieve the effect of reducing waste, improving screening effect, and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

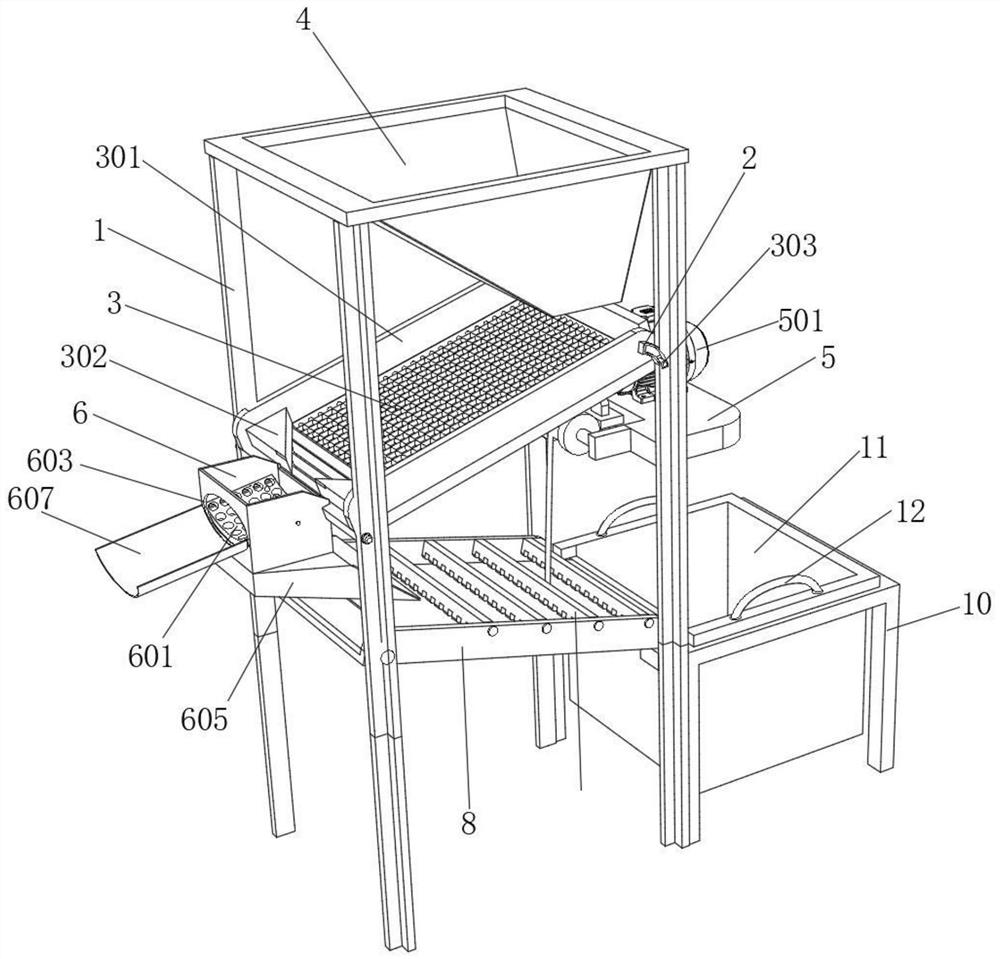

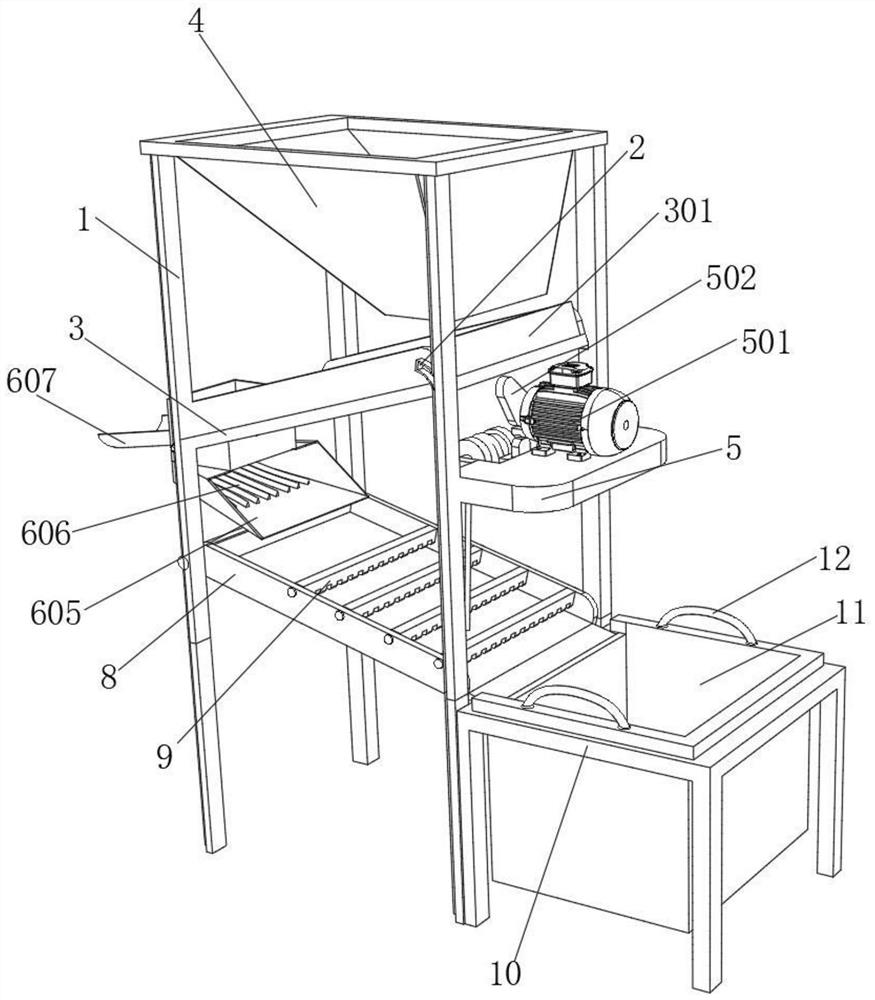

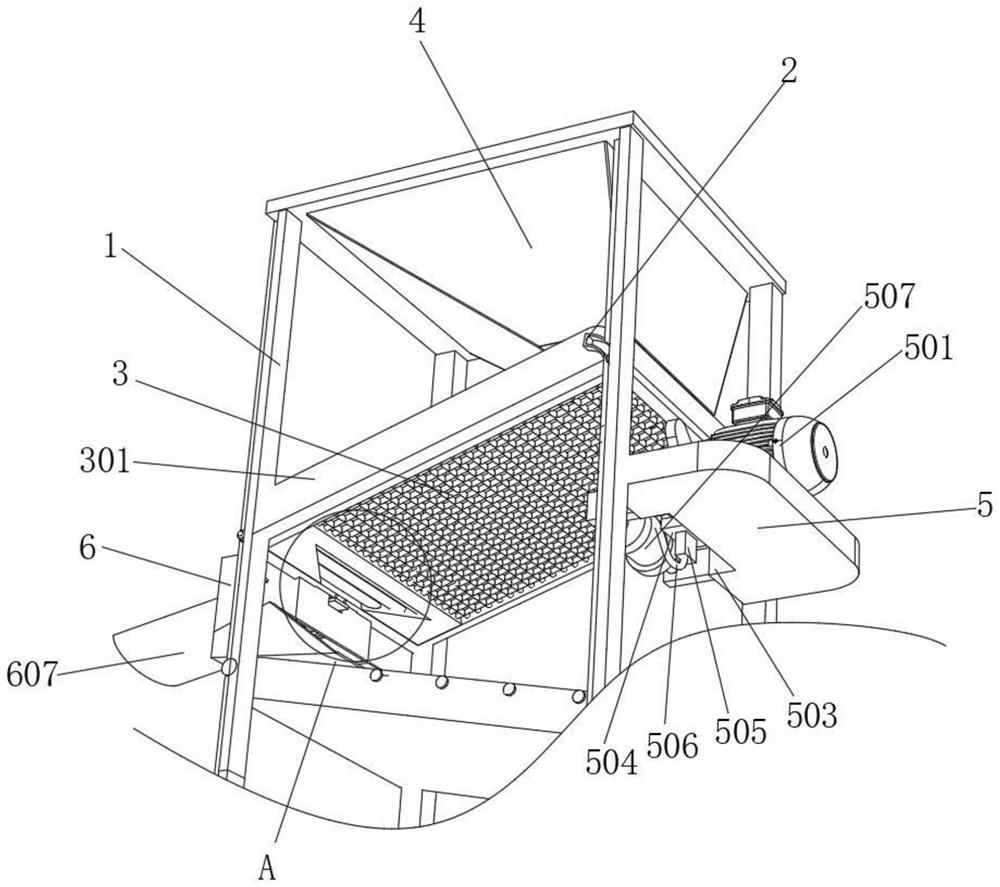

[0033] refer to Figure 1-Figure 5 , a continuous type sand screening device for construction engineering, comprising a first support frame 1, a screen 3 is rotatably connected to both sides of the first support frame 1, and both sides of the screen 3 are fixed with sliding shafts 303 by bolts. One side of a support frame 1 is fixed with an arc-shaped slideway 2 by bolts, and the arc-shaped slideway 2 is slidably connected with the sliding shaft 303, and the connection mode of the arc-shaped slideway 2 and the sliding shaft 303 can be slidably connected to the screen cloth 3. To guide the effect, the upper surface of the screen 3 is rotatably connected with a plurality of rolling shafts 304, and the upper surface of the screen 3 is fixed with a baffle 301 by bolts, and the sand and gravel on the screen 3 are blocked by the baffle 301 to prevent Sand and gravel fall from both sides of the screen 3, one side of the baffle plate 301 is fixed with a guide block 302 by bolts, one s...

Embodiment 2

[0037] refer to Figure 6-Figure 7 , a continuous type sand screening device for construction engineering, including a sliding rod 13 slidingly connected to both sides of the filter plate 8, one end of the sliding rod 13 is fixed with a sieve moving plate 1301 by bolts, and the sieve moving plate 1301 is slidably connected with the filter bar 9 , use the sliding rod to drive the screen moving plate to move to one side, so as to move the large sand and gravel to one side of the filter plate, and in the process, use the curved structure design of the screen moving plate to move the sand and gravel Rolling, so that sand and gravel can be separated from fine sand, one end of the sliding rod 13 is fixed with a pull rod 1302 by bolts.

[0038] The working principle of this embodiment: when in use, pull the sliding rod 13 outward, and use the sliding rod 13 to drive the sieve moving plate 1301 to move to one side, thereby moving the large sand and gravel to one side of the filter pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com