Gantry type double-station differential pressure casting main machine major component conveying device

A technology of differential pressure casting and conveying equipment, which is applied to casting equipment, manufacturing tools, metal processing equipment, etc., can solve problems affecting the health of operators, time-consuming and labor-intensive, etc., and achieve simple and reliable movements, stable gantry structure, and flexible and reliable movements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

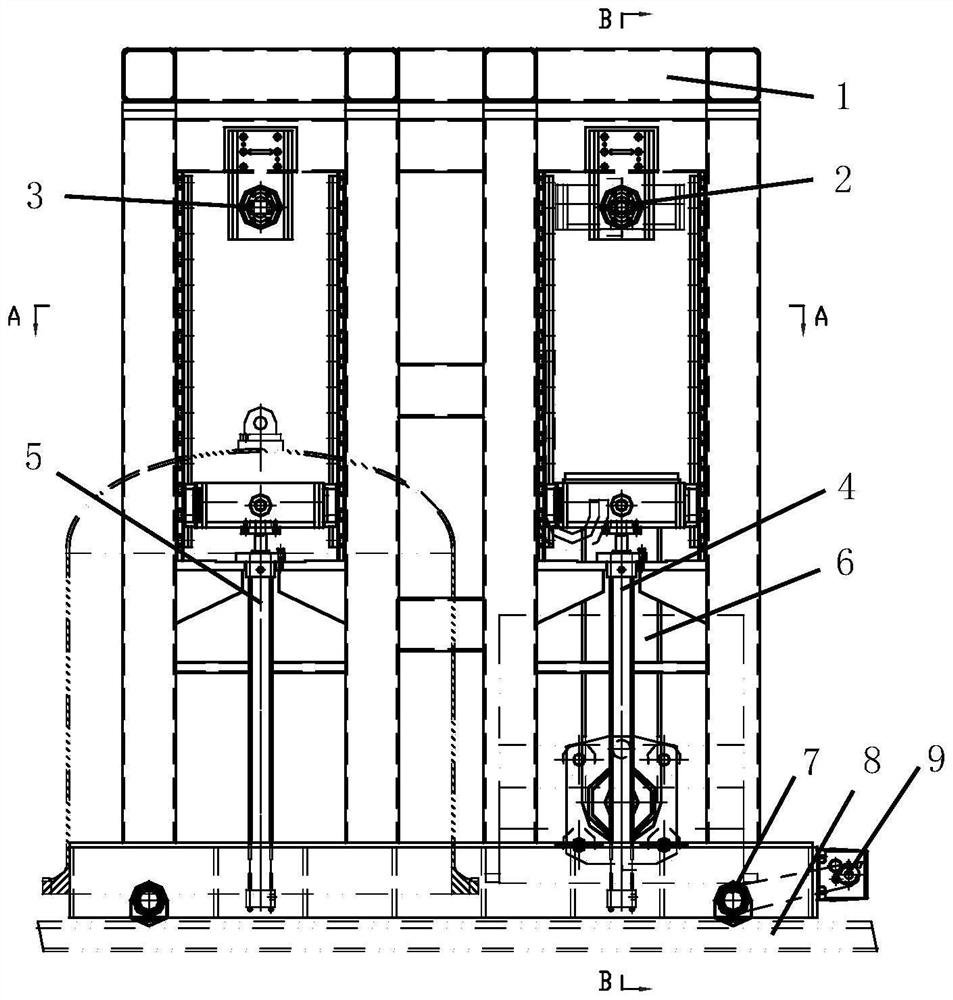

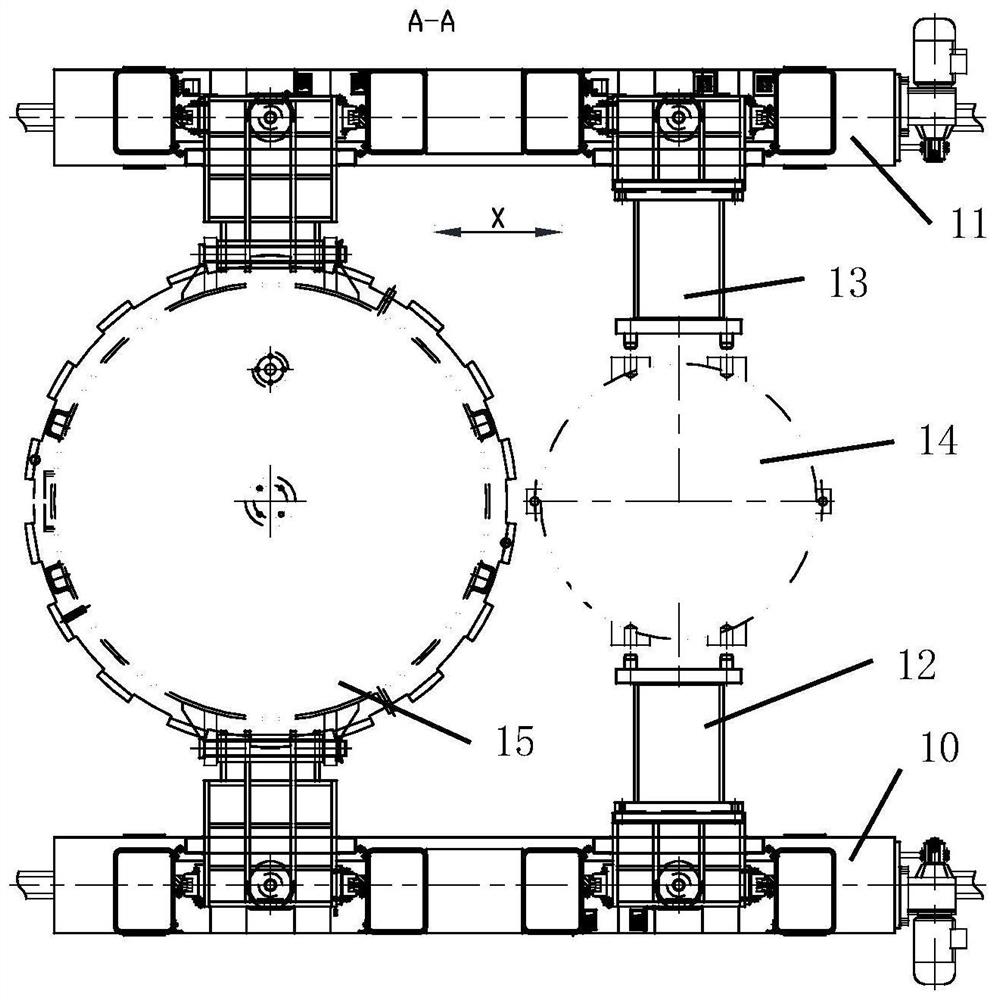

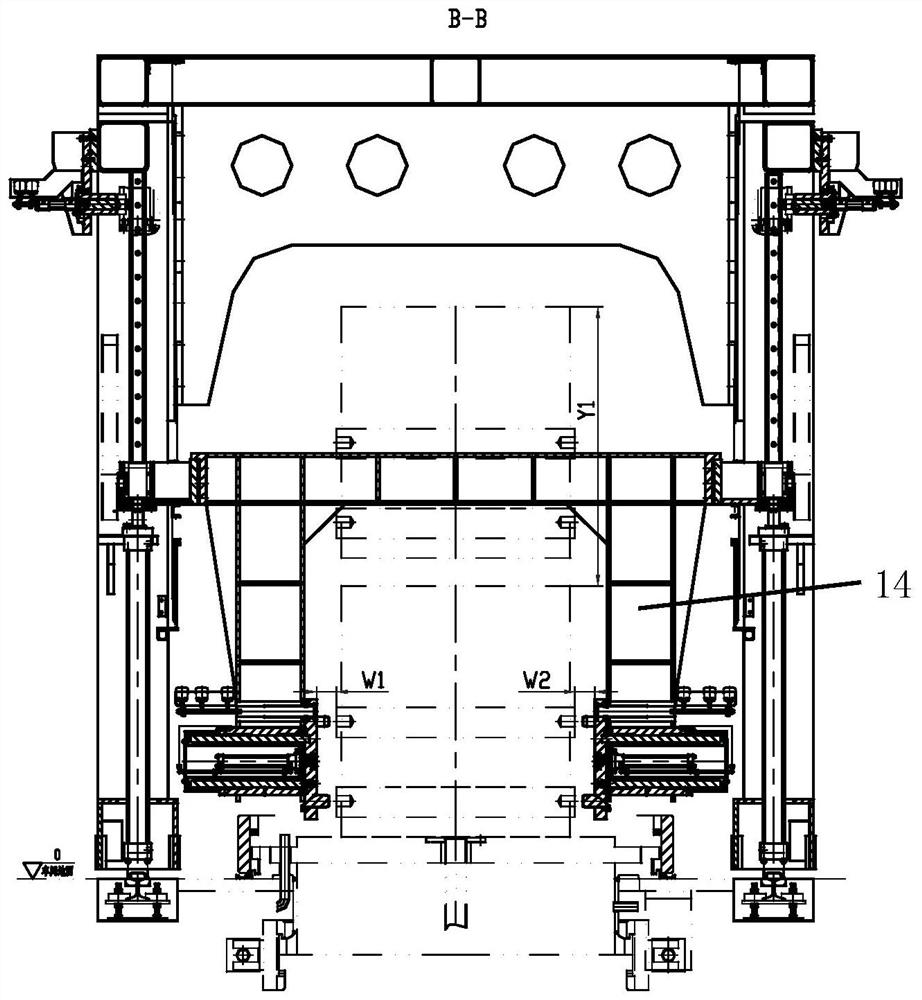

[0019] Regarding the aforementioned and other technical contents, features and effects of the present invention, refer to the appended figure 1 to attach image 3 It will be apparent from the detailed description of the embodiments. The structural contents mentioned in the following embodiments are all based on the accompanying drawings of the description.

[0020] Exemplary embodiments of the present invention will be described below with reference to the accompanying drawings.

[0021] The present invention provides a gantry-type double-station differential pressure casting main engine major component conveying device, which mainly solves the problem of automatic and reliable transportation of sand molds and tanks. The solution is to use a gantry conveying device to realize the X-direction horizontal transportation of the sand mold and the upper tank at the same time. At the same time, there are two stations for the sand mold and the upper tank, and the sand mold and the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com