Method and device for extracting solute from gaseous solvents

A gas solvent and solute technology, applied in solvent extraction, liquid solution solvent extraction, separation methods, etc., can solve problems such as high cost, difficult removal of compressor lubricant, equipment corrosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

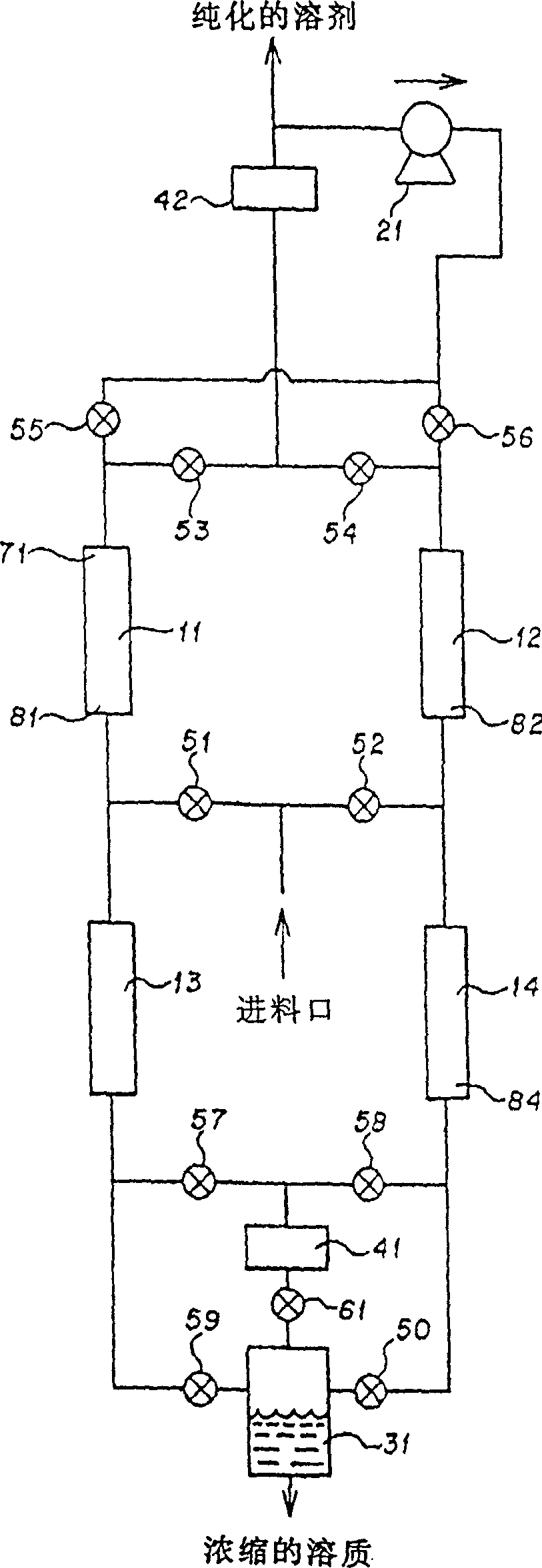

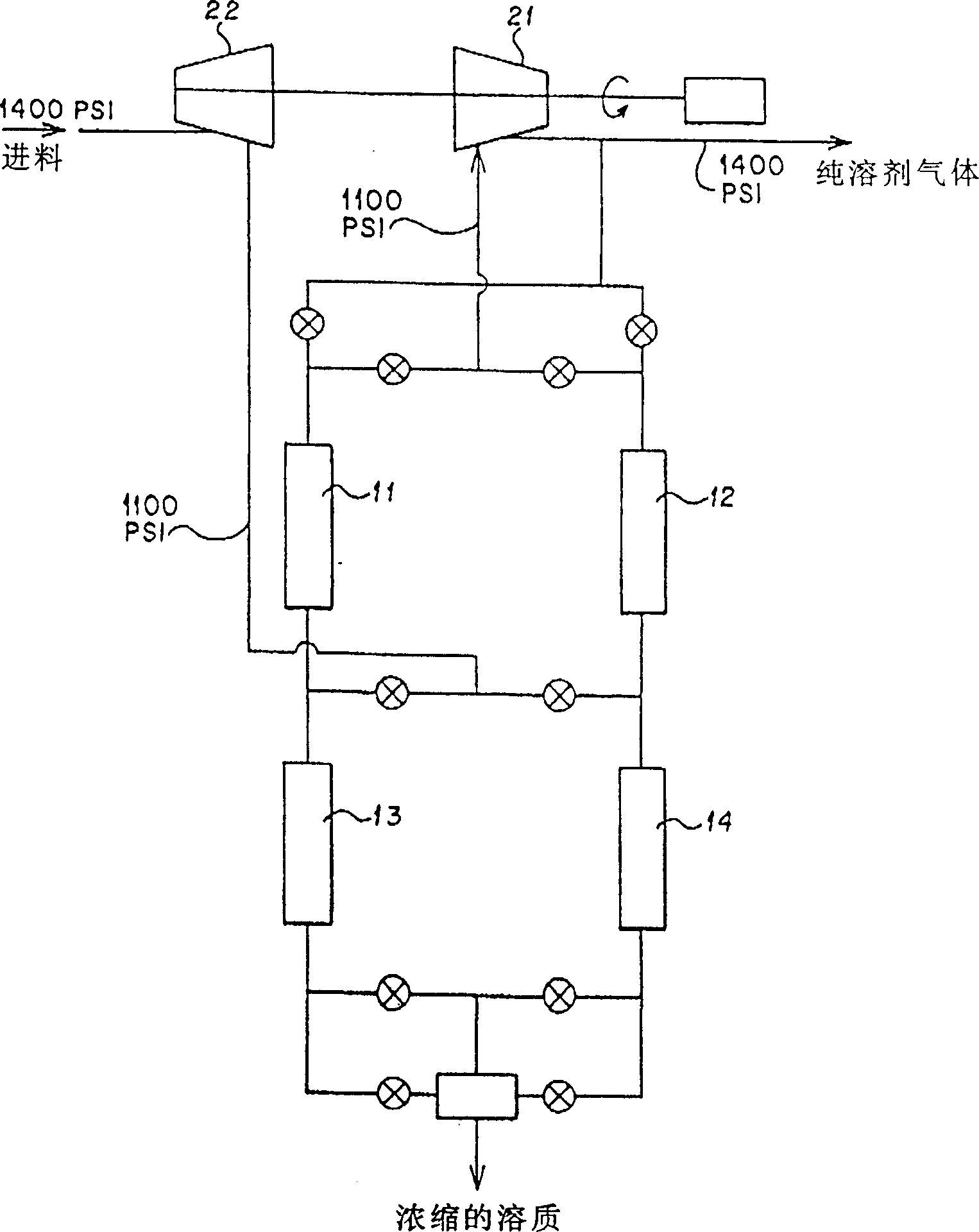

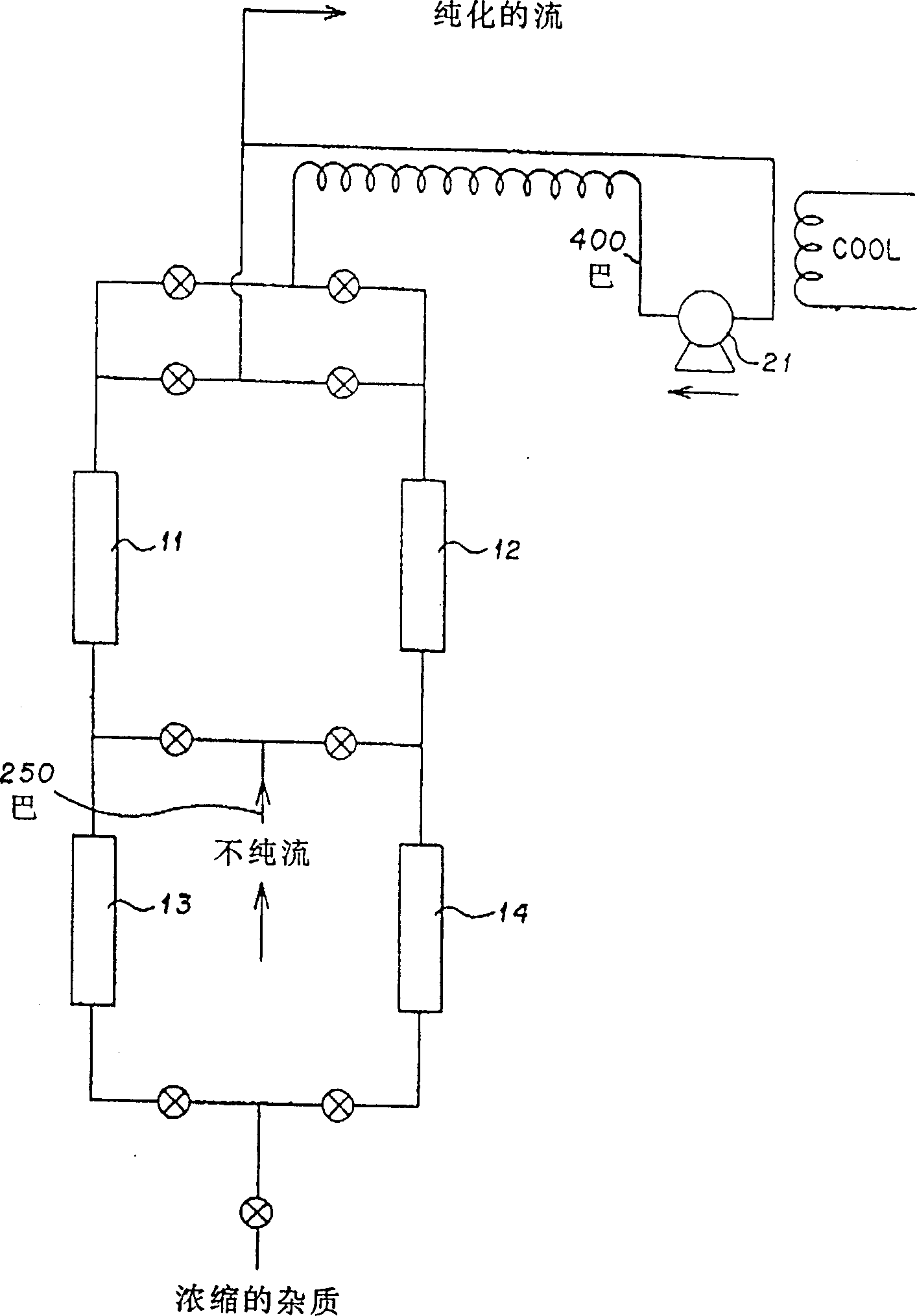

[0079]The present invention provides a method complementary to pressure swing adsorption, in which the gas solution is purified by absorption in an adsorption bed, then the pressure and density are increased, and the adsorption bed is regenerated using flow in the opposite direction.

[0080] In the method of the present invention, at least one solute dissolved in the gas solvent is separated from the gas solvent under the condition that the chemical potential of the at least one solute dissolved in the gas solvent decreases as the density of the gas solvent increases come out. In operating the method, a solute-containing gas solvent is passed through an adsorption bed at a first density and in a first direction so that the solute is adsorbed by the adsorption bed, and then the gas solvent or a portion thereof is treated to increase its density To a level higher than the original density, at this time, the affinity of the gas solvent with the second density to the solute adsor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com