Method and apparatus for mixing

A liquid and container technology, applied in the field of devices and methods for mixing, can solve problems such as disturbing production, shortening the service life of containers, etc., to achieve the effect of reducing power requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The method and apparatus of the invention will now be described with respect to a laboratory scale version of a settler. The following description is only for describing the present invention, and is by no means intended to limit the scope of the present invention. In addition, industrial precipitators for the Bayer process have also been manufactured. This industrial type of settler has a diameter of about 11 meters and a height of about 28 meters. It corresponds to a volume of about 2.7 megaliters. The following description is also exemplary only, and is not intended to limit the interpretation of the scope of the present invention.

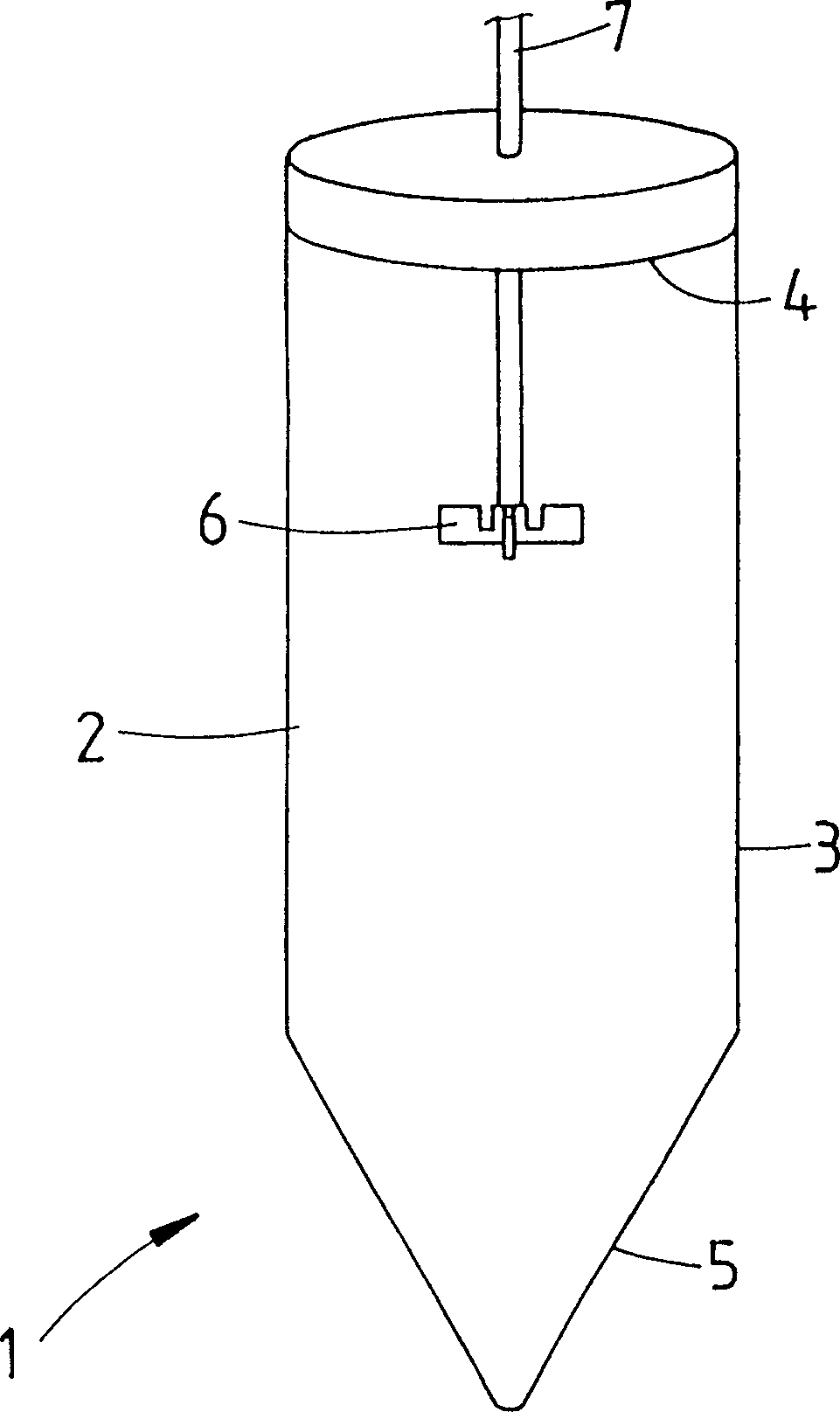

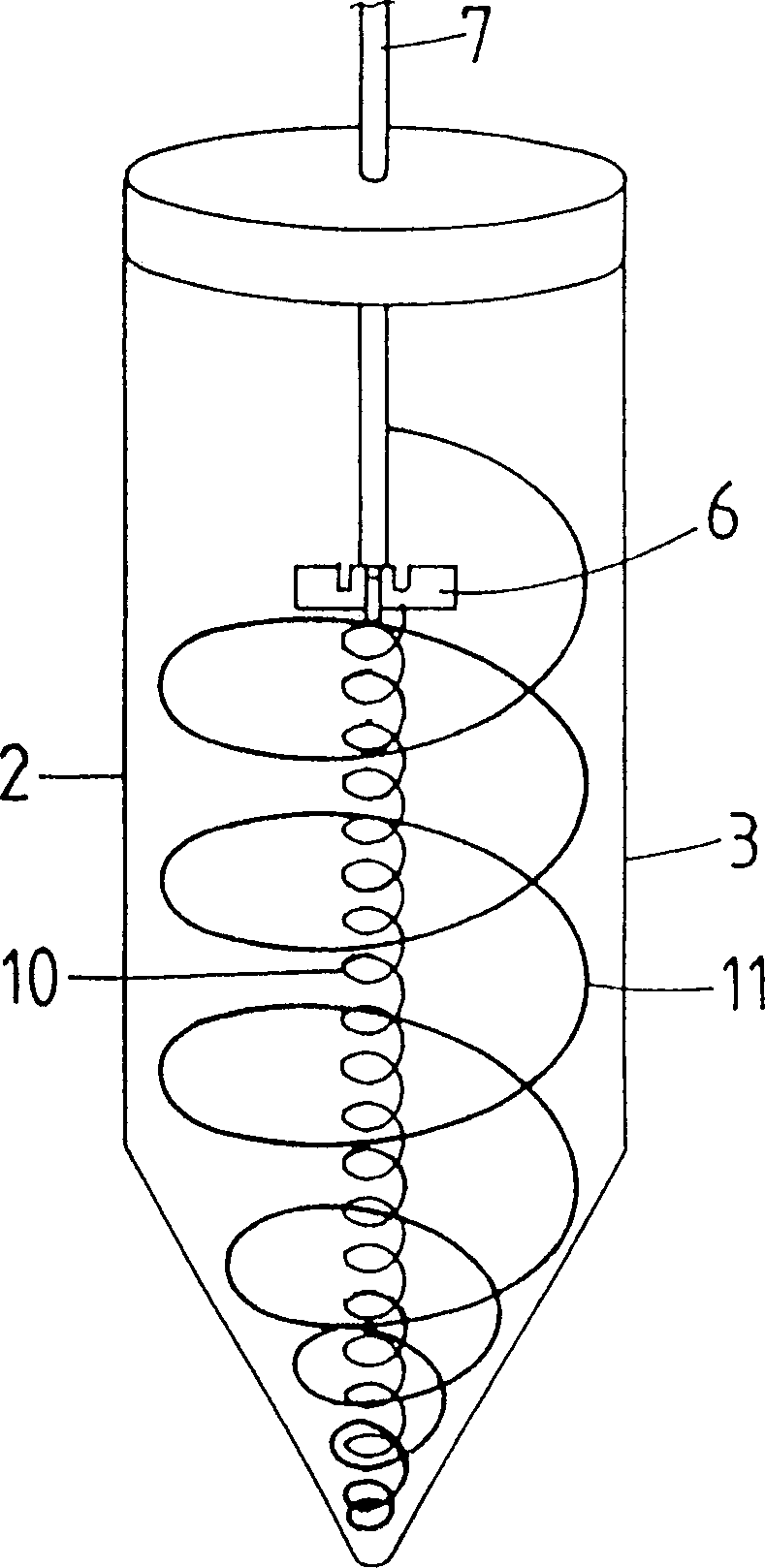

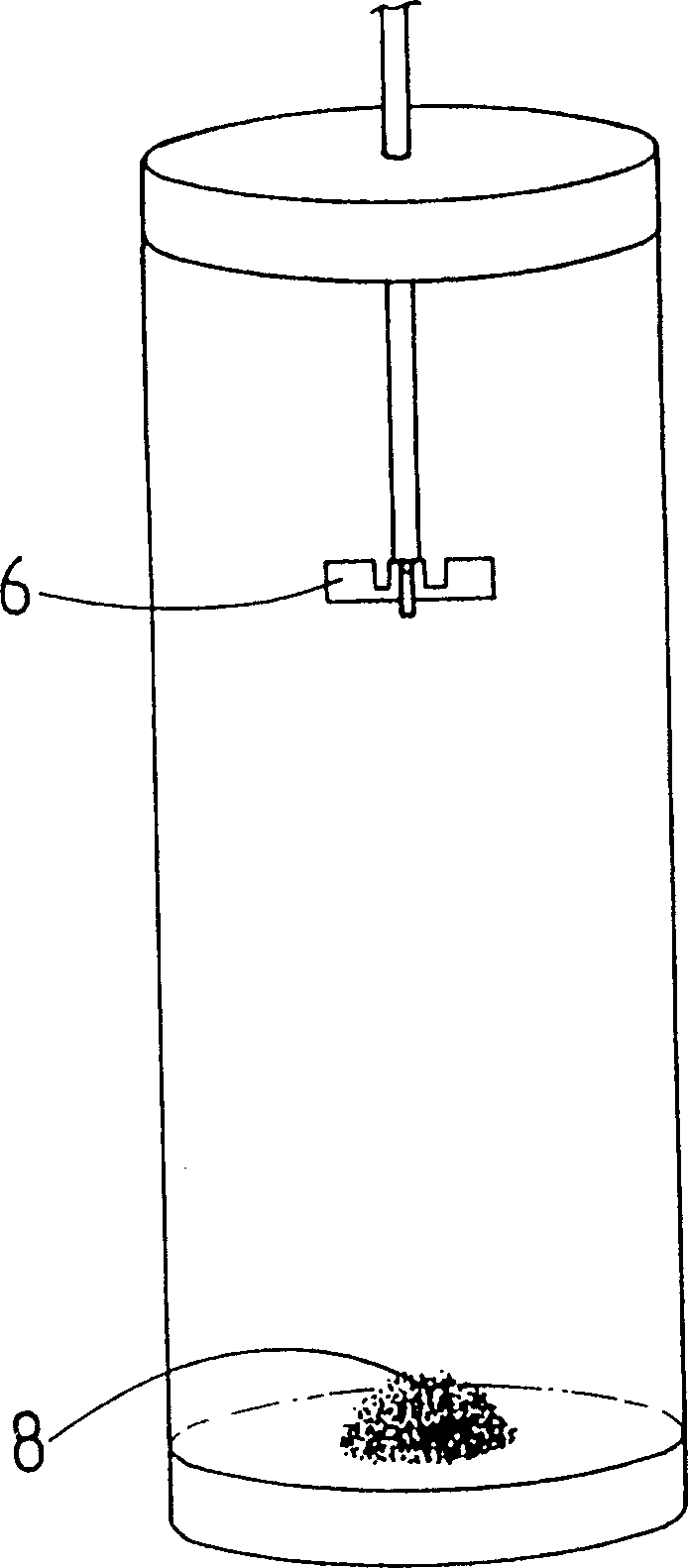

[0024] Such as figure 1 As shown, the settler 1 according to the invention comprises a vessel 2 consisting of a smooth-walled vertical cylinder 3 having an upper end 4 and a conical bottom 5 . A Rushton turbine 6 is mounted on a shaft 7 rotated by a drive motor (not shown). The laboratory-scale type of precipitator is the figure 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com