Long-service-life pavement structure based on sandwich structure and construction method thereof

A pavement structure and sandwich technology, which is applied to cohesive pavement paved on site, roads, roads, etc., can solve the problems of thick pavement and low service life, and achieve the goal of reducing pavement thickness, reducing pavement thickness, and strong waterproof damage ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

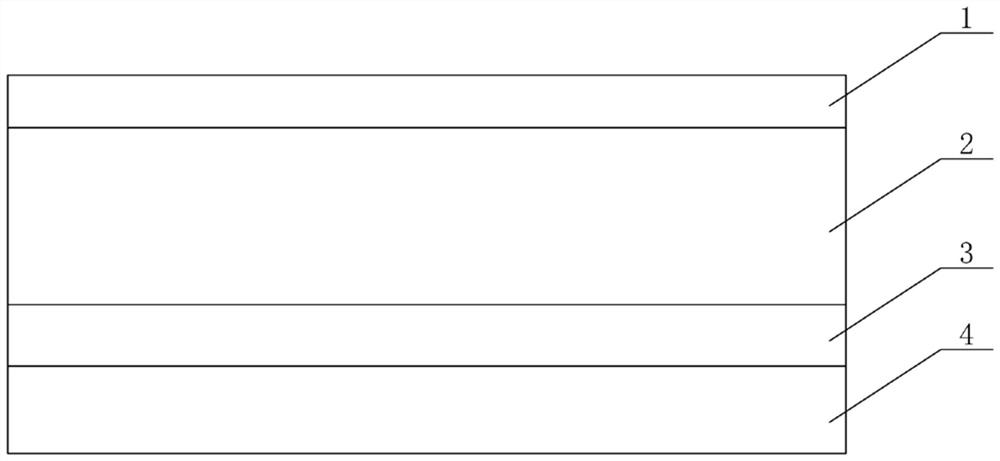

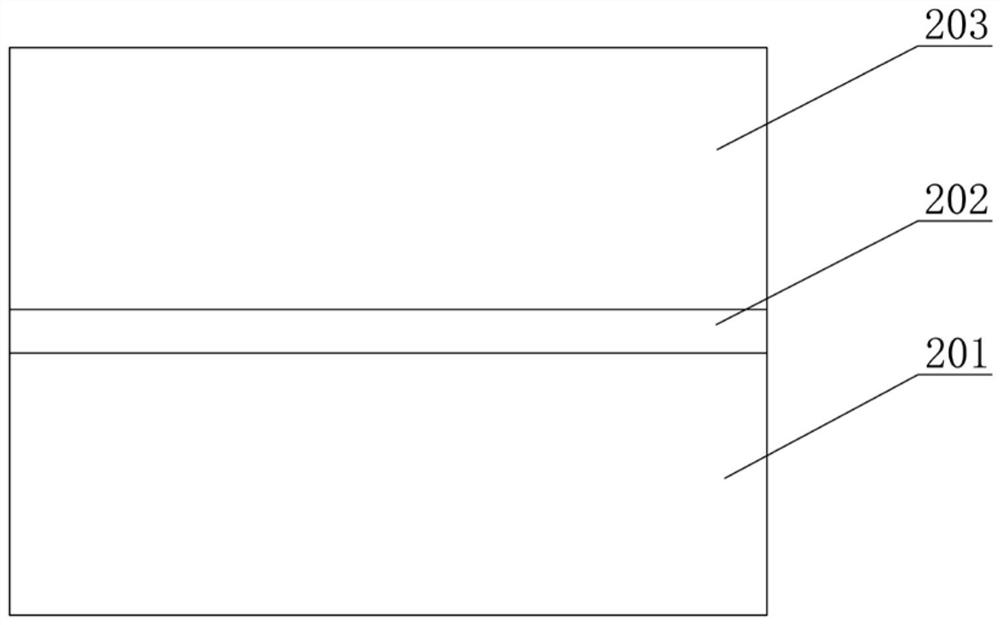

[0041] Such as Figure 1 to Figure 5 As shown, a long-life pavement structure based on a sandwich structure, including a sandwich upper layer 1, a sandwich lower layer 2, a sandwich environment transition layer 3 and an improved and reinforced soil road base 4, the number of layers of the improved and reinforced soil road base 4 is composed of The road grade and loading conditions are determined. Specifically, the improved and reinforced soil road base 4 is composed of 5 layers of improved and reinforced soil layers with a thickness of 25 cm. The improved and reinforced soil layers are composed of gravel soil or lime soil or other reinforced soils. The average compaction degree of each layer of improved and reinforced soil layer must meet the specification requirements, and the deflection value of the top surface of the improved and reinforced soil layer should be less than 0.6 times of the design deflection value of the top surface of the subgrade.

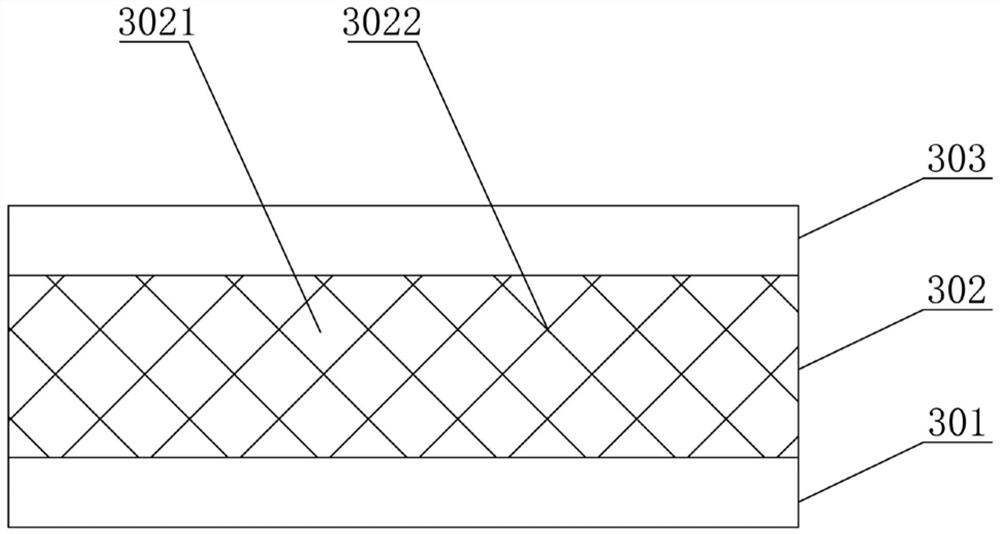

[0042] A sandwich environ...

Embodiment 2

[0047] A long-life pavement structure based on a sandwich structure, including a sandwich upper layer 1, a sandwich lower layer 2, a sandwich environment transition layer 3 and an improved and reinforced soil road base 4. Specifically, the improved and reinforced soil road base 4 is composed of 2 layers thick The composition of the improved and reinforced soil layer is 20cm. The improved and reinforced soil layer is composed of gravel soil or lime soil or other reinforced soil. The average compaction degree of each layer of improved and reinforced soil layer must meet the specification requirements. The deflection value should be less than 0.85 times of the design deflection value of the top surface of the subgrade; the number of layers of the improved and reinforced soil road base 4 is determined by the road grade and load conditions.

[0048] A sandwich environment adaptation transition layer 3 is provided above the improvement and reinforcement soil road base 4. Specifically...

Embodiment 3

[0053]A long-life pavement structure based on a sandwich structure, including a sandwich upper layer 1, a sandwich lower layer 2, a sandwich environment transition layer 3 and an improved and reinforced soil road base 4. Specifically, the improved and reinforced soil road base 4 is 8 layers thick The composition of the improved and reinforced soil layer is 30cm. The improved and reinforced soil layer is composed of gravel soil or lime soil or other reinforced soil. The average compaction degree of each layer of improved and reinforced soil layer must meet the requirements of the specification. The deflection value should be less than 0.35 times of the design deflection value of the top surface of the subgrade; the number of layers of the improved and reinforced soil road base 4 is determined by the road grade and load conditions.

[0054] A sandwich environment adaptation transition layer 3 is provided above the improvement and reinforcement soil road base 4. Specifically, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com