Rib plate unloading type combined steel pile supporting and anchoring structure and application

A technology of ribs and steel piles, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems affecting earthwork excavation and basement construction speed, complex structure, long construction period, etc., achieve small deformation, increase resistance Overturning moment, high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

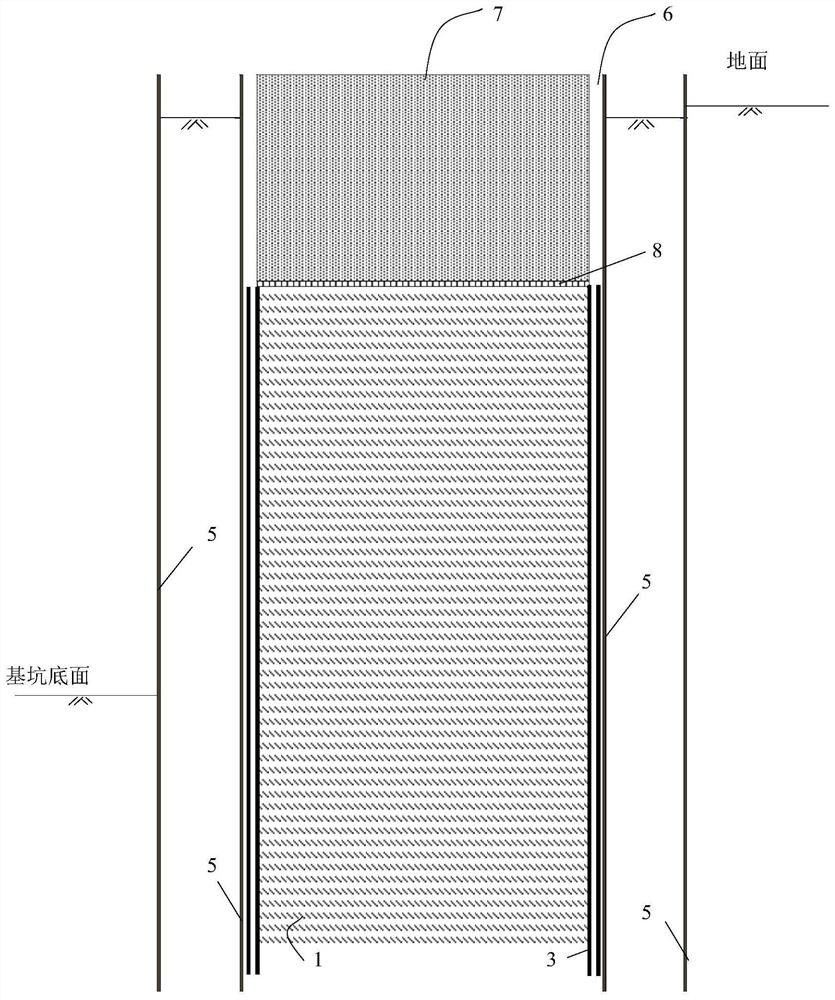

[0052] The application of the present invention in deep foundation pit support or cofferdam engineering, its steps are as follows:

[0053] 1) Preparatory work: prefabricated the sub-components of the continuous wall, the parent components and the rib sub-components of the ribs, and the rib parent components, set hydrophobic epoxy on the outer wall of the mortise of the continuous wall sub-components and the inner wall of the female component. Resin coating, transportation of prefabricated parts to the construction site;

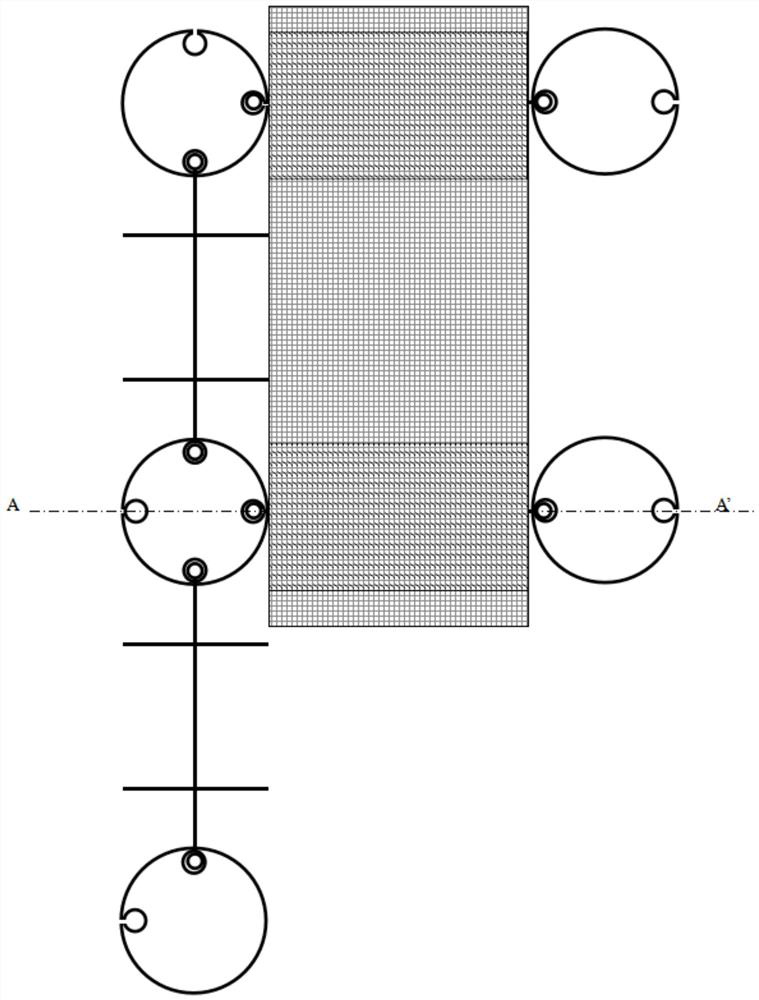

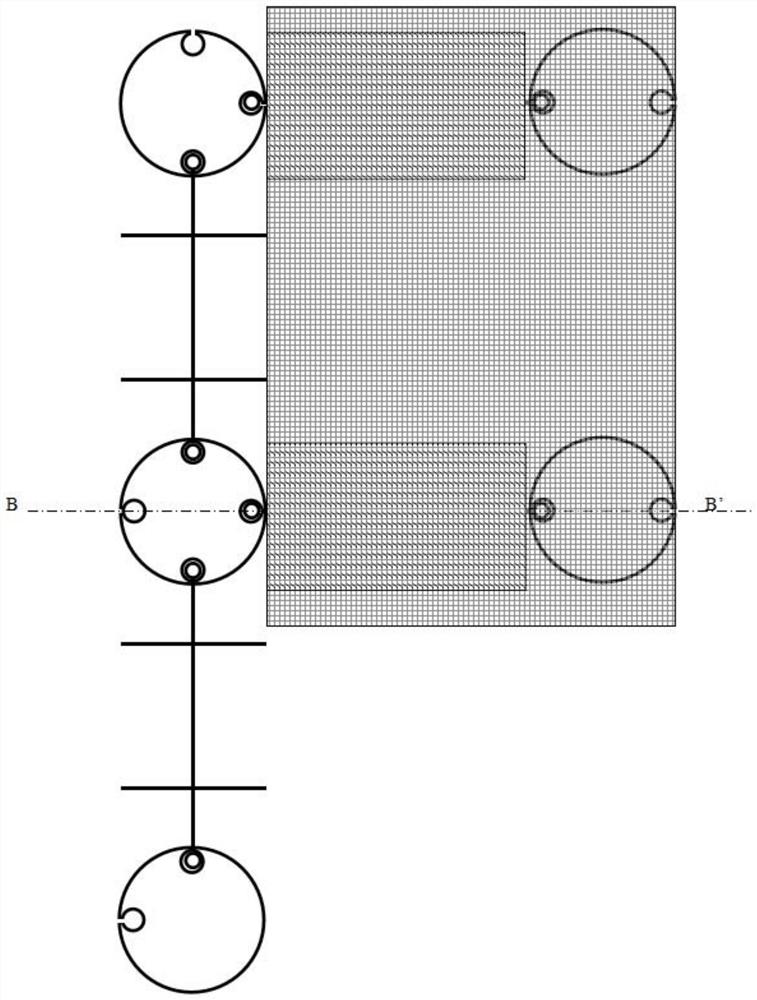

[0054] 2) Install the diaphragm wall: Construct the mother component and sub-component in sequence on the side wall of the foundation pit to form a diaphragm wall support structure;

[0055] 3) Install the ribs: Construct the rib sub-components and the rib parent components in sequence on the outside of the continuous wall to the design depth;

[0056] 4) Excavation: Excavate the soil above the ribs and between the ribs until the top surface of the ribs is ...

Embodiment 2

[0065] The application of the present invention in bank revetment slope protection project, its construction steps are as follows:

[0066] a) Preparatory work: prefabricated the sub-components of the diaphragm wall, the mother members and the rib sub-members of the ribs, and the rib mother members. Resin coating, transportation of prefabricated parts to the construction site;

[0067] b) Diaphragm wall installation: Construct mother components and sub-components in sequence at the design position of slope revetment or bank revetment to form a diaphragm wall support structure;

[0068] c) Install the ribs: Construct the rib sub-components and the rib parent components in sequence on the outside of the continuous wall to the design depth;

[0069] d) Excavation: Excavate the soil above the top surface of the ribs and between the ribs until the top surface of the ribs is exposed;

[0070] e) Set the anti-filter layer: set the anti-filter layer or concave-convex drainage board ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com