High-sealing-performance vacuumizing device

A vacuuming device and high-sealing technology, which is applied to liquid variable volume machinery, variable volume pump components, machines/engines, etc. Improve the quality of vacuuming, avoid air leakage, and facilitate the effect of switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be more clearly and completely described below by way of a preferred embodiment with reference to the accompanying drawings, but the present invention is not limited to the scope of the described embodiment.

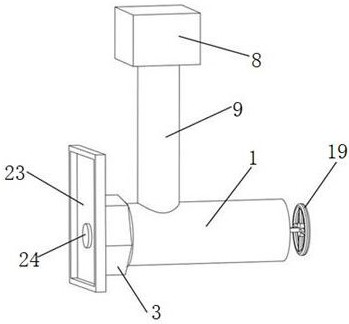

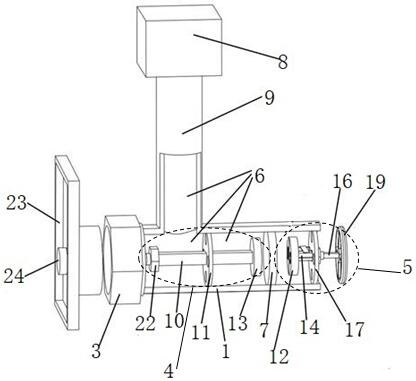

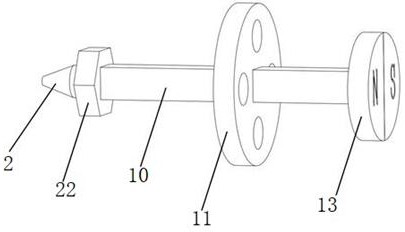

[0027] Such as figure 1 and figure 2 Shown is a high-tightness vacuuming device disclosed by the present invention, which includes a main vacuum pipeline 1, and one end of the main vacuum pipeline 1 is concentrically provided with a conical body 2 for conducting with the end to be vacuumed. The outer concentric sleeve with one end of the cone 2 is provided with a nut 3 for sealing connection with the end to be vacuumed, and a sliding guide mechanism is provided in the main vacuum pipeline 1 for the cone 2 to move along the axis of the main vacuum pipeline in a vacuum environment 4, and the driving mechanism 5 used to drive the movable part of the sliding guide mechanism 4 to move back and forth; between the sliding guiding mechanism 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com