Method for automatic contact survey of ultra-deep vertical shaft

An automatic measurement and shaft technology, which is used in measurement devices, measurement instruments, surveying and navigation, etc., can solve the problems of inability to meet the requirements of high-precision construction measurement, reduction of measurement accuracy and timeliness, and poor stability of measurement results. The effect of aiming error, manpower saving, and measurement efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] A preferred implementation method of the present invention will be described in further detail below in conjunction with the accompanying drawings.

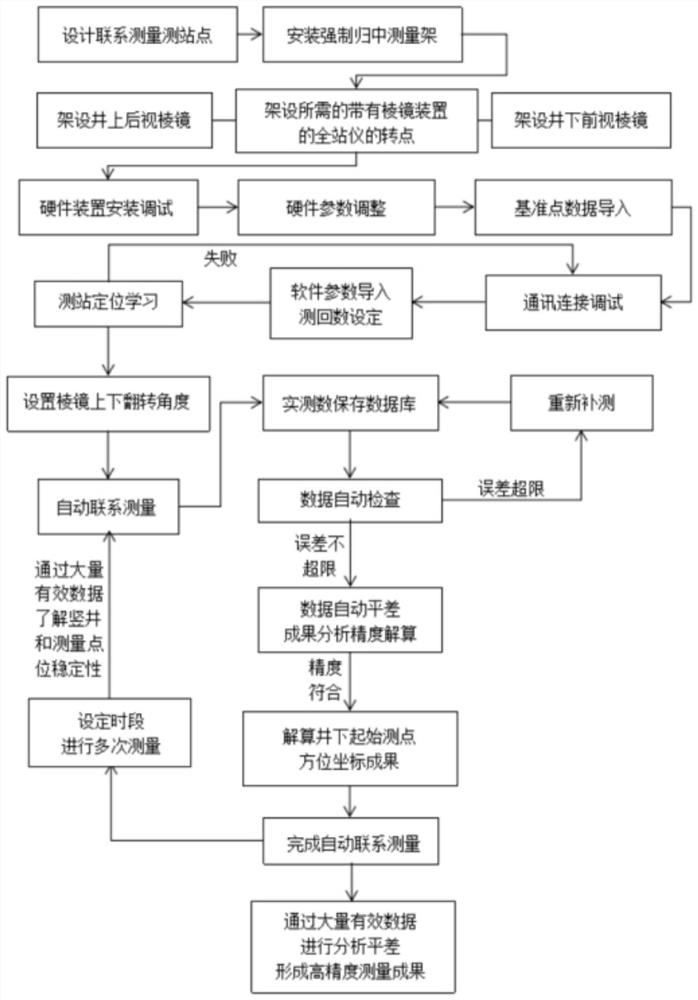

[0017] like figure 1 , figure 2 As shown, a kind of ultra-deep vertical shaft automatic contact measurement method of the present invention, specifically comprises the following steps:

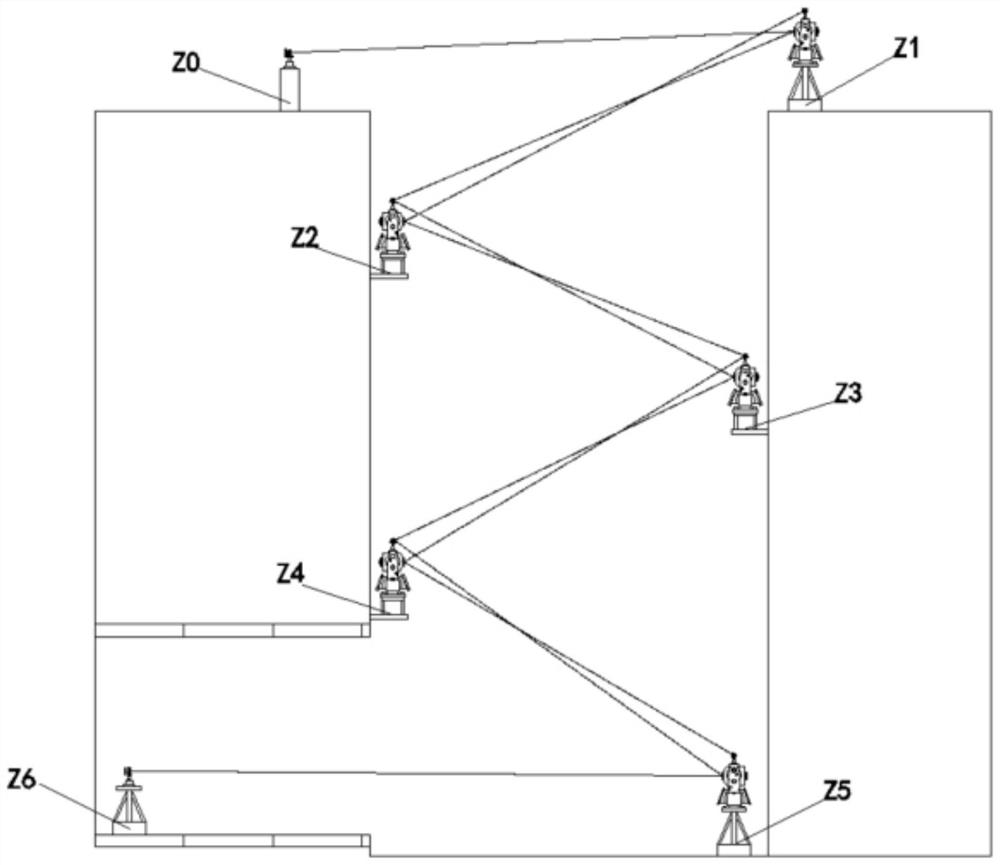

[0018] 1) To design the station for automatic contact measurement, a total of 5 total stations with automatic measurement function and prism flipping device and 2 prisms are required, including: known station Z1: 1 total station, known on the well Measuring point ZO: 1 rear-view prism, turning points Z2, Z3, Z4 on the well wall: 3 total stations, downhole starting station Z5: 1 total station, downhole starting point Z6: 1 front As a prism, the side lengths of Z1, Z2, Z3, Z4, and Z5 stations are all greater than 15 meters, and the observation elevation angle of adjacent stations is 24°. And install the forced centering measuring frame a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com