Nucleation-free tungsten deposition

A nucleation layer, tungsten fluoride technology, applied in the direction of coating, gaseous chemical plating, electric solid device, etc., can solve the problem of low resistance film and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

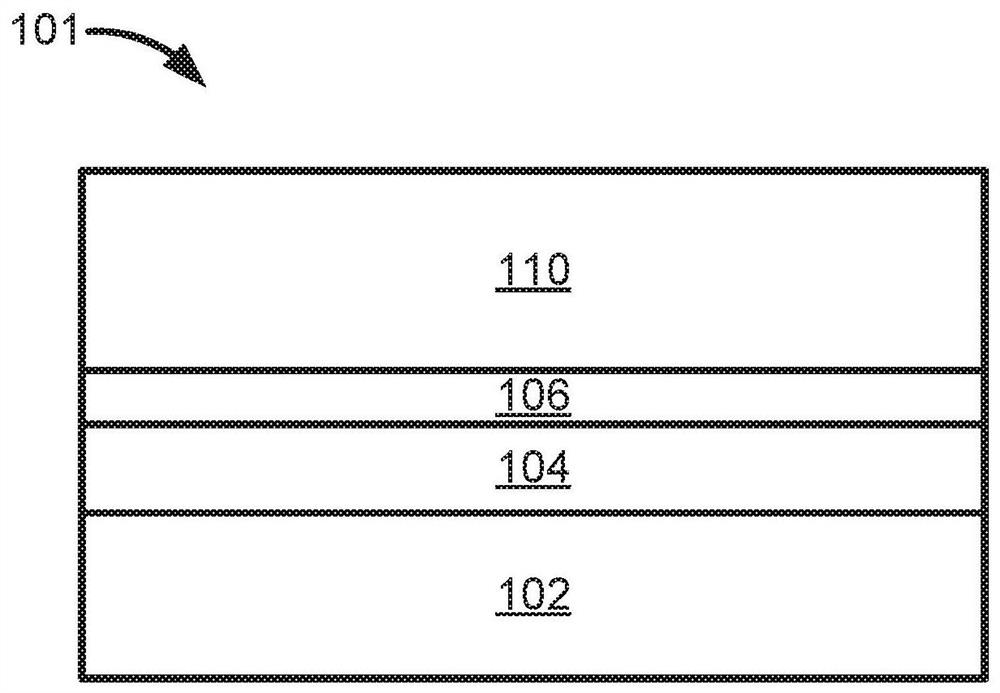

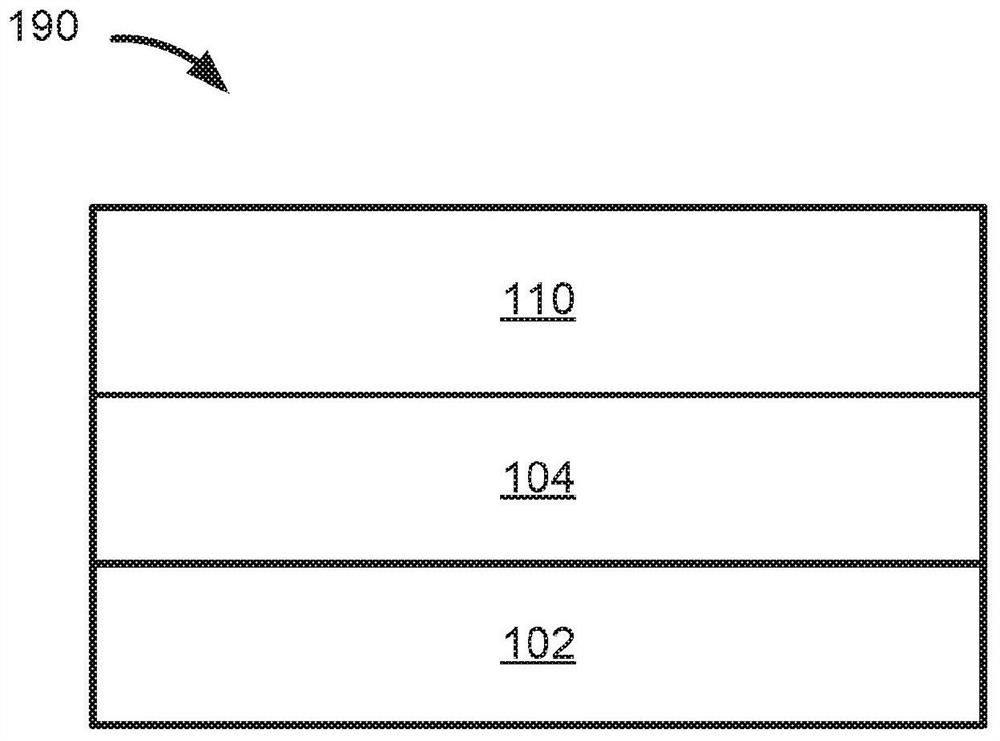

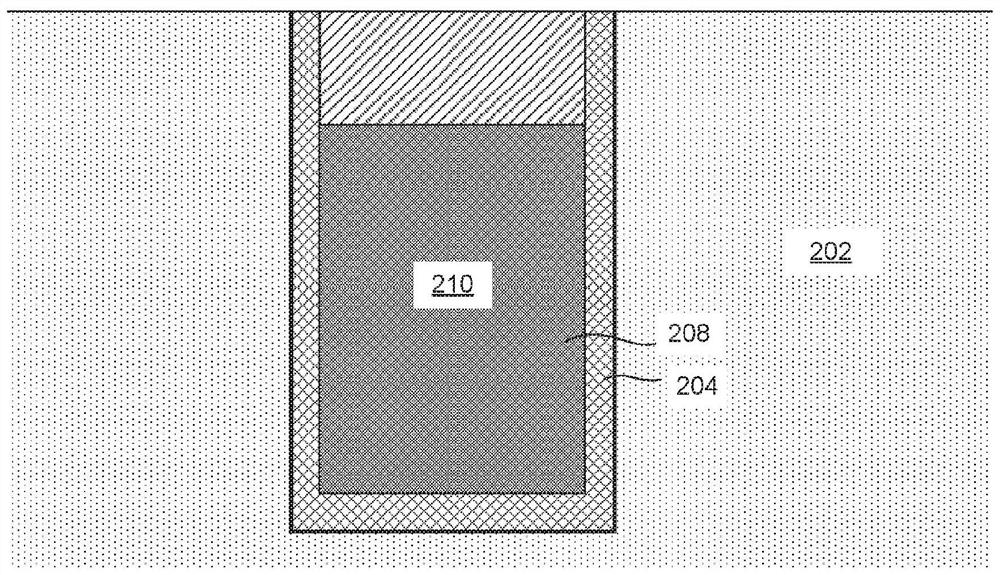

[0028] Provided herein are methods and apparatus for forming metal films, such as tungsten (W) films, on semiconductor substrates. The method includes forming a silicon (Si) and / or boron (B) sacrificial layer prior to depositing a bulk metal layer on the substrate. The sacrificial layer reacts with the metal precursor to form part of the bulk layer. In this way, tungsten can be deposited directly on surfaces such as diffusion barriers or dielectric surfaces without depositing a nucleation layer. Apparatus for performing the methods are also provided.

[0029] Forming electrical contacts or lines in semiconductor device fabrication may include filling features with tungsten or other conductive materials. A nucleation layer may first be deposited into the vias or contacts. A nucleation layer is a thin conformal layer used to facilitate the subsequent formation of host material thereon. A tungsten nucleation layer may be deposited to conformally coat the sidewalls and bottom ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile stress | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com