Head switching device for 3D printing

A 3D printing and print head technology, applied in coating devices, additive processing, etc., can solve the problem of difficulty in expanding the number of split print heads, and achieve the effect of solving the problem of print head expansion and improving flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

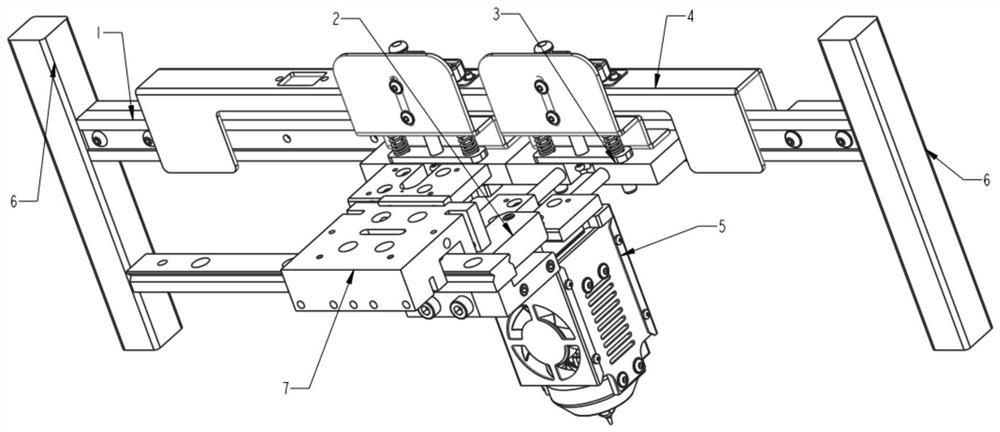

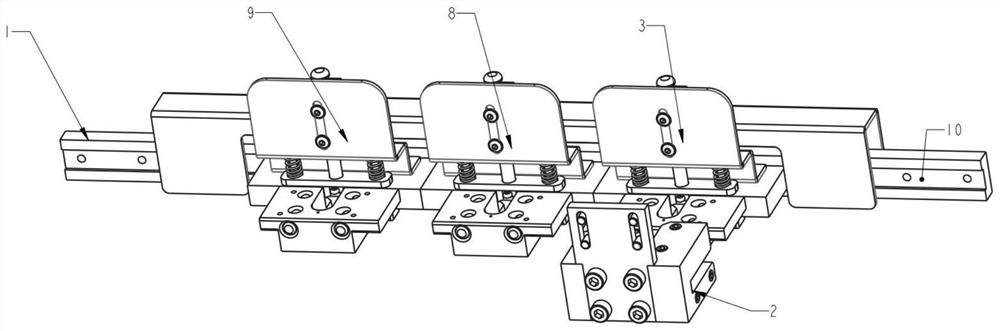

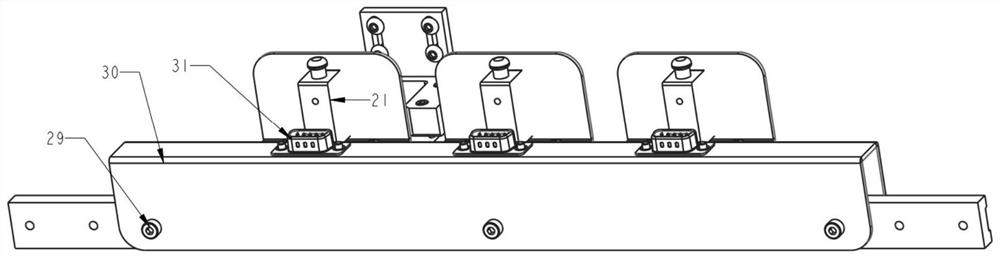

[0022] The invention belongs to a multi-print head replacement device for a 3D printer. The multiple print heads of the printer are designed in columns, and they are respectively placed in the corresponding print head storage modules. The printer grasps and returns according to the control of the program. Print head, to achieve print head switching. The device is fixed on the frame 6 of the 3D printer and consists of a general support 1 , a print head grabber 2 , a print head storage module 3 , a print head connector 4 and a printer moving mechanism 7 . The basic idea is to design a print head storage module 3 to store the print head 5, one print head storage module 3 can store one print head 5; The device 2 calls the print head that needs to be used or returned. The print head storage module 3 is installed in the positioning groove 10 of the total s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com