Vertical take-off and landing and fixed wing hovercars

A flying car and vertical take-off and landing technology, applied to vertical take-off and landing aircraft, aircraft, vehicles that can be converted into airplanes, etc., can solve problems such as blade tip shock wave vibration, easy yaw when wind blows, flight instability, etc. , to achieve the effect of maintaining flight stability, taking into account vertical take-off and landing, and reducing the workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

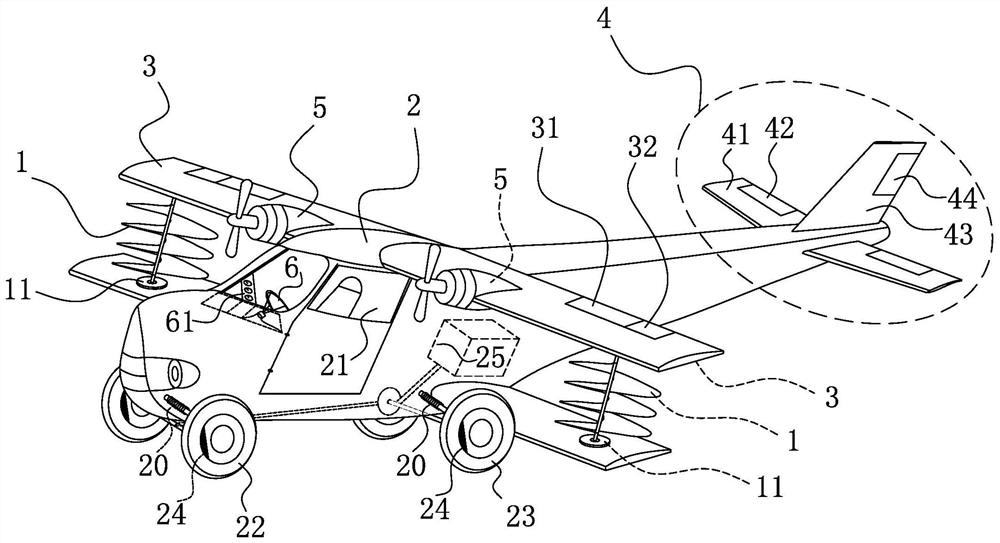

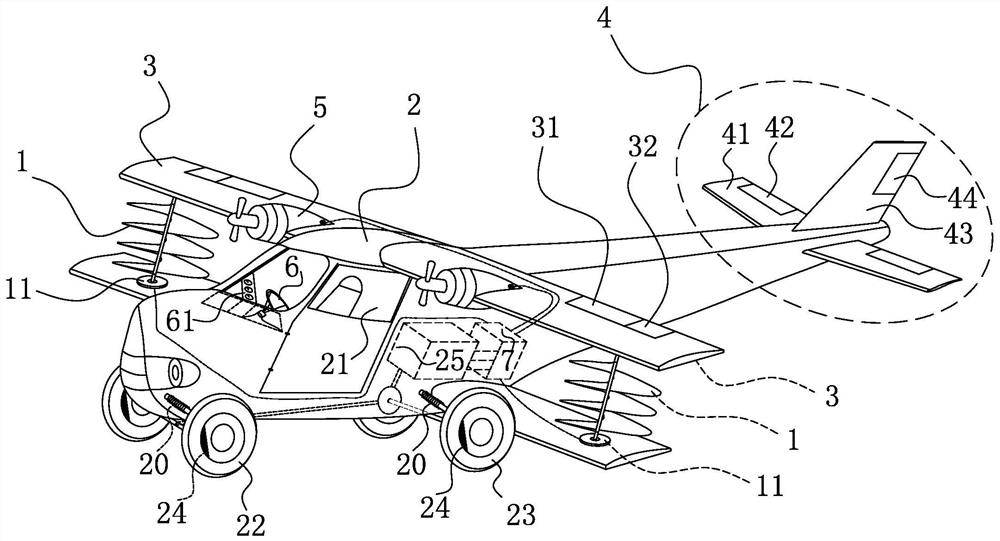

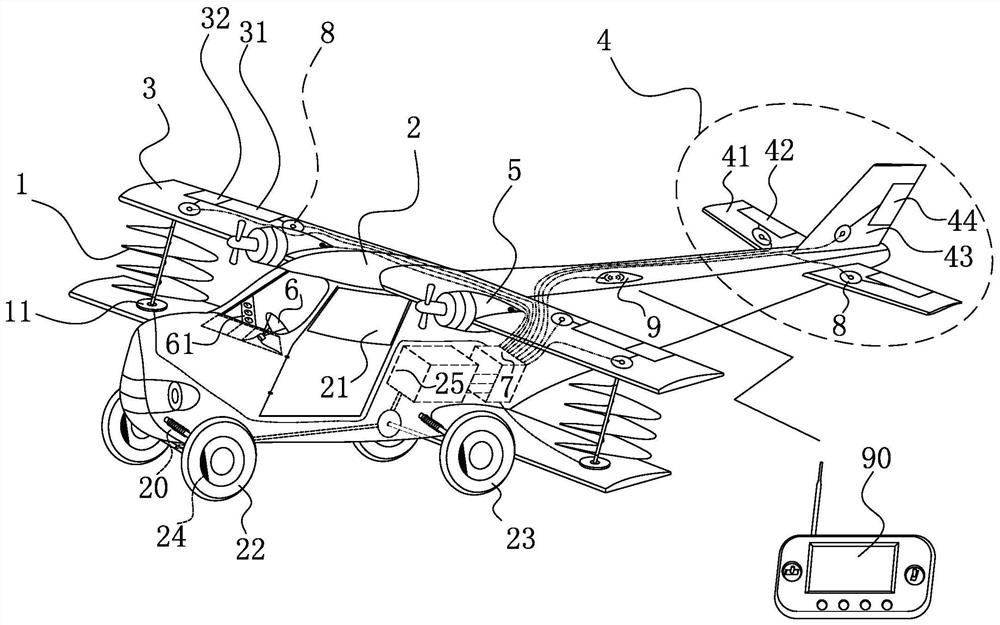

[0064] figure 1 It is embodiment 1 of vertical take-off and landing and fixed-wing flying vehicle of the present invention. It is adapted to use the engine to provide all driving power. As shown in the figure, the flap 31 is arranged on the rear edge of the main wing 3 near the position of the vehicle body 2, and the aileron 32 is arranged on the rear edge of the main wing 3 away from the position of the vehicle body 2; the elevator 42 is arranged on the rear edge of the horizontal tail 41, The rudder 44 is arranged on the rear edge of the vertical tail 43; the multi-layer continuous airfoil propeller 1 is a multi-layer continuous spiral airfoil structure, which is connected and driven to rotate by the power unit 11; the root of the main wing 3 is fixed on both sides of the vehicle body 2; The empennage 4 is fixed on the tail of the vehicle body 2;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com