Automatic arranging, conveying and auxiliary adjusting system for bottle bodies

A technology for adjusting the system and bottles, which is applied in the direction of conveyors, mechanical conveyors, conveyor objects, etc., can solve the problem of low level of automatic bottle collection, low efficiency of bottle collection, and troublesome collection operations and other problems, to achieve the effects of easy collection and processing, good bottle adjustment effect, and good finishing and conveying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

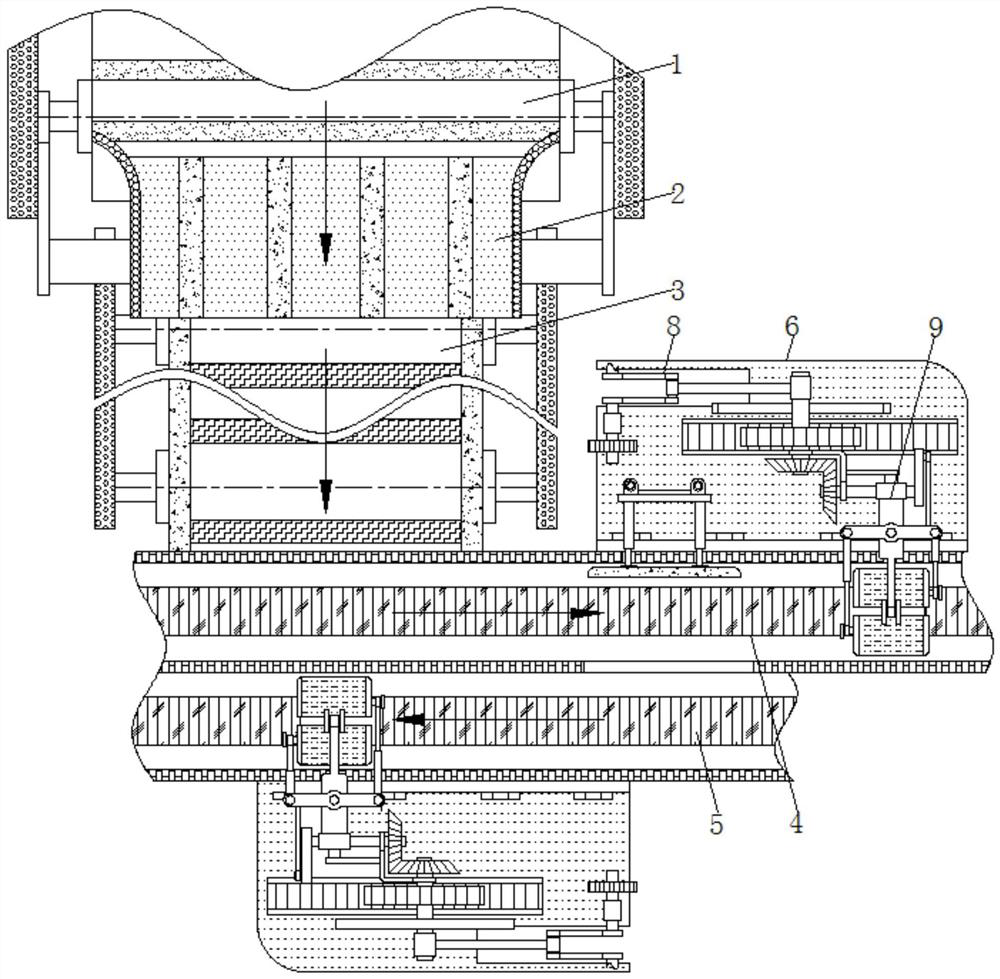

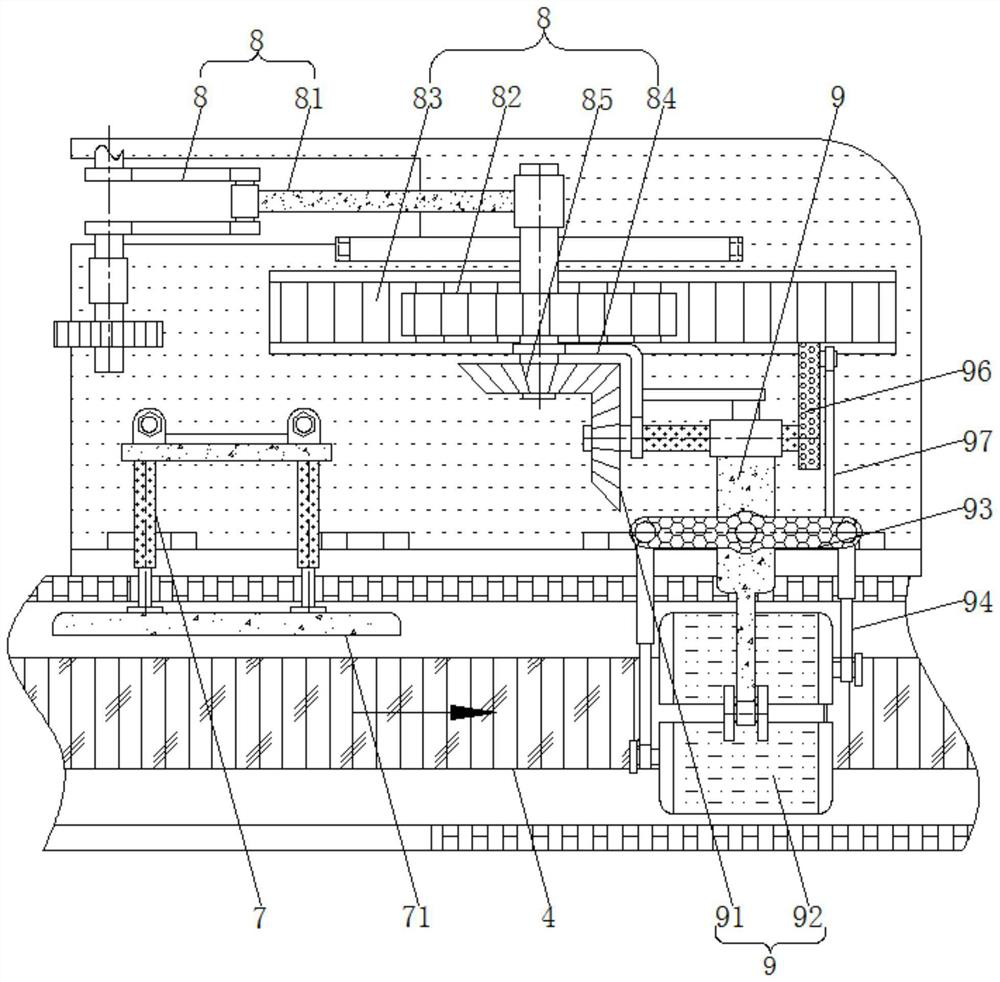

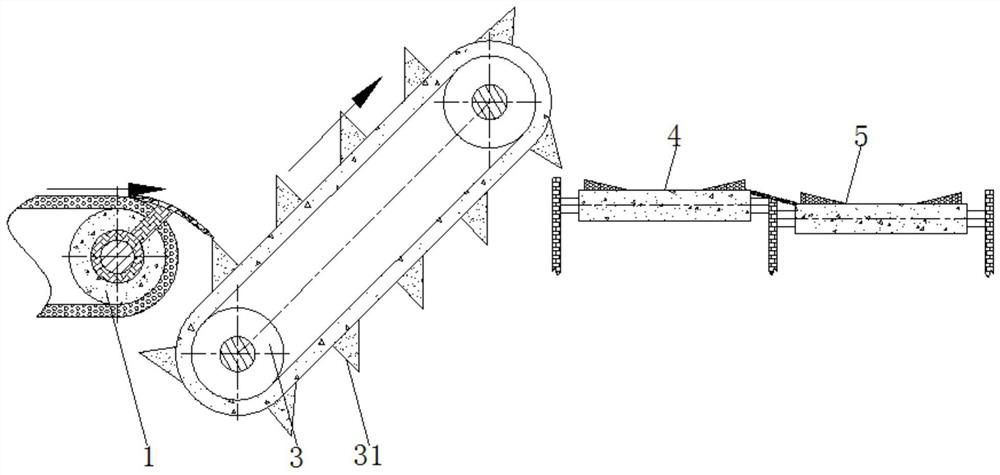

[0028] see Figure 1-4 , an automatic sorting, conveying and auxiliary adjustment system for bottles, comprising a conveyor belt 1 for conveying bottles, a guide plate 2 is provided on the surface of the conveyor belt 1, and the guide plate 2 is designed as an arc-shaped plate, and the end far away from the conveyor belt 1 is connected to the conveyor belt The surface of 3 corresponds to the surface of the conveyor belt 3, which is used to arrange and guide the bottles to the conveyor belt 3. The conveyor belt 3 is provided on the side of the conveyor belt 1 close to the guide plate 2. The conveyor belt 3 adopts an upward slope design and is used to transport the bottles to the In device one 4, push plates 31 are provided on the surface of the conveyor belt 3, and the push plates 31 are evenly distributed on the surface of the conveyor belt 3 for conveying the bottles.

[0029] The side of the conveyor belt 3 away from the guide plate 2 is provided with a conveying device one ...

Embodiment 2

[0033] see Figure 1-4 , an automatic sorting, conveying and auxiliary adjustment system for bottles, comprising a conveyor belt 1 for conveying bottles, a guide plate 2 is provided on the surface of the conveyor belt 1, and the guide plate 2 is designed as an arc-shaped plate, and the end far away from the conveyor belt 1 is connected to the conveyor belt The surface of 3 corresponds to the surface of the conveyor belt 3, which is used to arrange and guide the bottles to the conveyor belt 3. The conveyor belt 3 is provided on the side of the conveyor belt 1 close to the guide plate 2. The conveyor belt 3 adopts an upward slope design and is used to transport the bottles to the In device one 4, push plates 31 are provided on the surface of the conveyor belt 3, and the push plates 31 are evenly distributed on the surface of the conveyor belt 3 for conveying the bottles.

[0034] The side of the conveyor belt 3 away from the guide plate 2 is provided with a conveying device one ...

Embodiment 3

[0039] see Figure 1-4 , an automatic sorting, conveying and auxiliary adjustment system for bottles, comprising a conveyor belt 1 for conveying bottles, a guide plate 2 is provided on the surface of the conveyor belt 1, and the guide plate 2 is designed as an arc-shaped plate, and the end far away from the conveyor belt 1 is connected to the conveyor belt The surface of 3 corresponds to the surface of the conveyor belt 3, which is used to arrange and guide the bottles to the conveyor belt 3. The conveyor belt 3 is provided on the side of the conveyor belt 1 close to the guide plate 2. The conveyor belt 3 adopts an upward slope design and is used to transport the bottles to the In device one 4, push plates 31 are provided on the surface of the conveyor belt 3, and the push plates 31 are evenly distributed on the surface of the conveyor belt 3 for conveying the bottles.

[0040] The side of the conveyor belt 3 away from the guide plate 2 is provided with a conveying device one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com