Monorail crane rail mounting vehicle

A monorail crane and installation vehicle technology, applied to vehicles with cranes, hoisting devices, transportation and packaging, etc., can solve problems such as hidden safety hazards, low installation efficiency, and no transportation function, so as to improve work efficiency and improve safety. , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

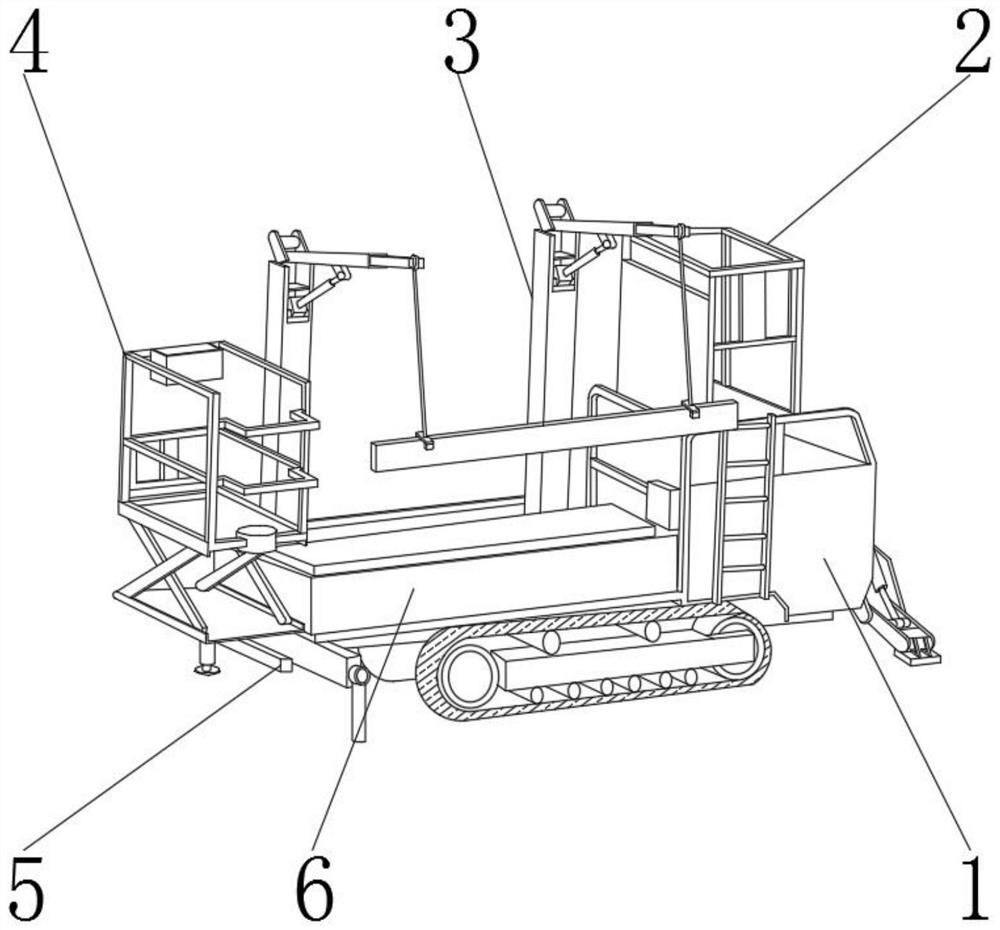

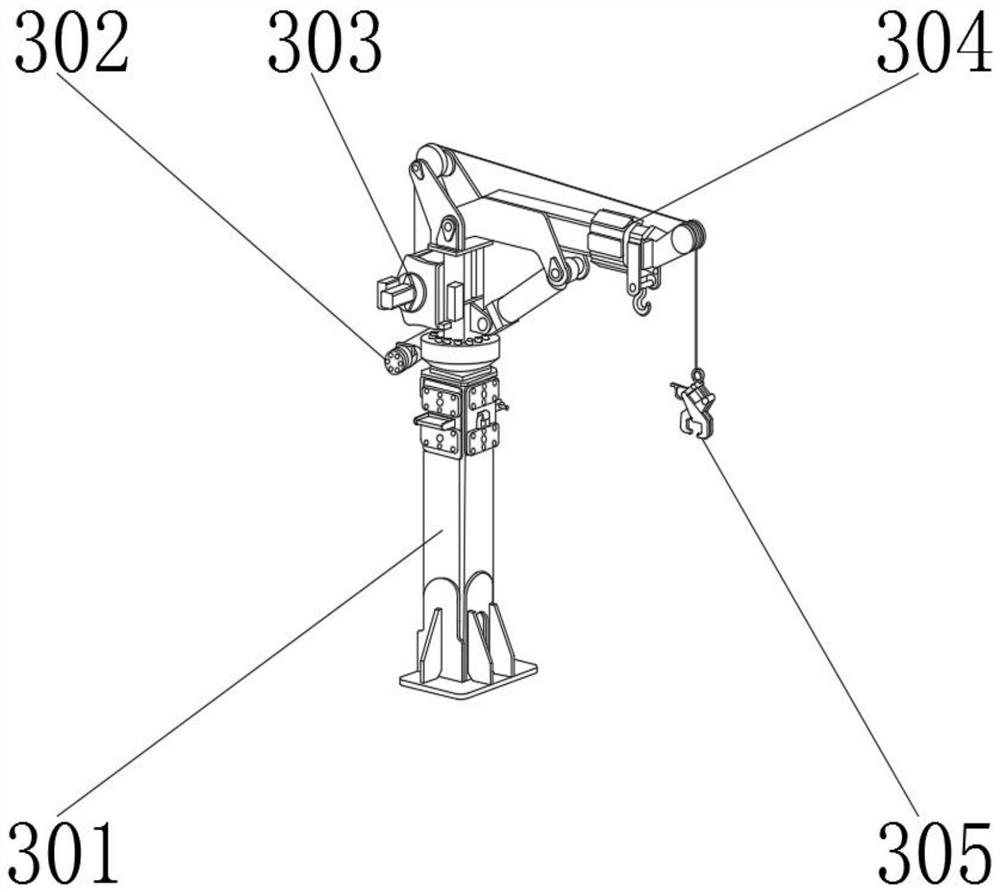

[0017] like Figure 1-2 As shown, the monorail crane track installation vehicle includes a nose 1, a transport mechanism 6 is arranged on the outer surface of one end of the nose 1, a front platform 2 is arranged on one side outer surface of the transport mechanism 6, and a front platform 2 is arranged on the other side outer surface of the transport mechanism 6. A rear platform 4 is provided, a vehicle stabilizing mechanism 5 is provided on the outer surface of the lower end of the transport mechanism 6, and a lifting arm 3 is provided on the outer surface of the upper end of the transport mechanism 6. The lifting arm 3 includes a boom 301, an angle adjustment device 302, a lifting device 303, The forearm 304, the snatch device 305, the angle adj...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap