Hole repairing device for measuring pavement compactness through sand filling method

A technology of compaction and sand filling method, which is applied in the direction of road repair, road, road, etc., and can solve the problems of increasing measurement error, weight reduction, and damage to the blade of the first knife edge, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

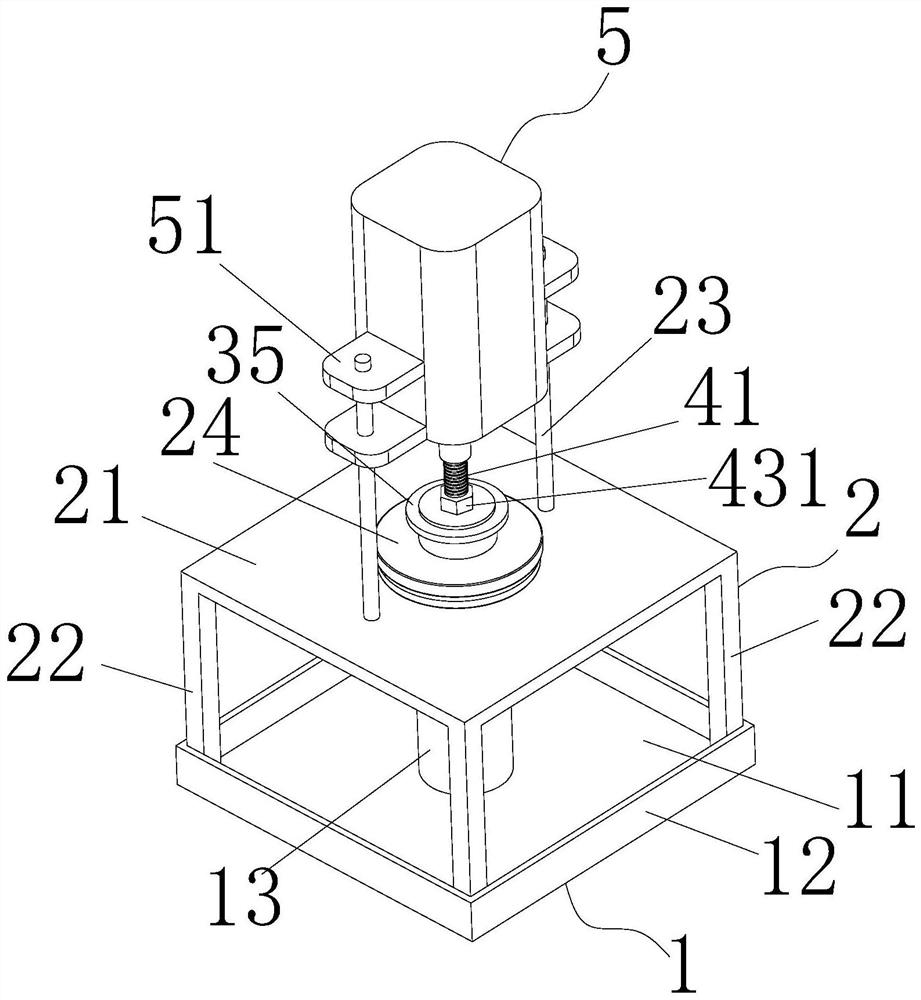

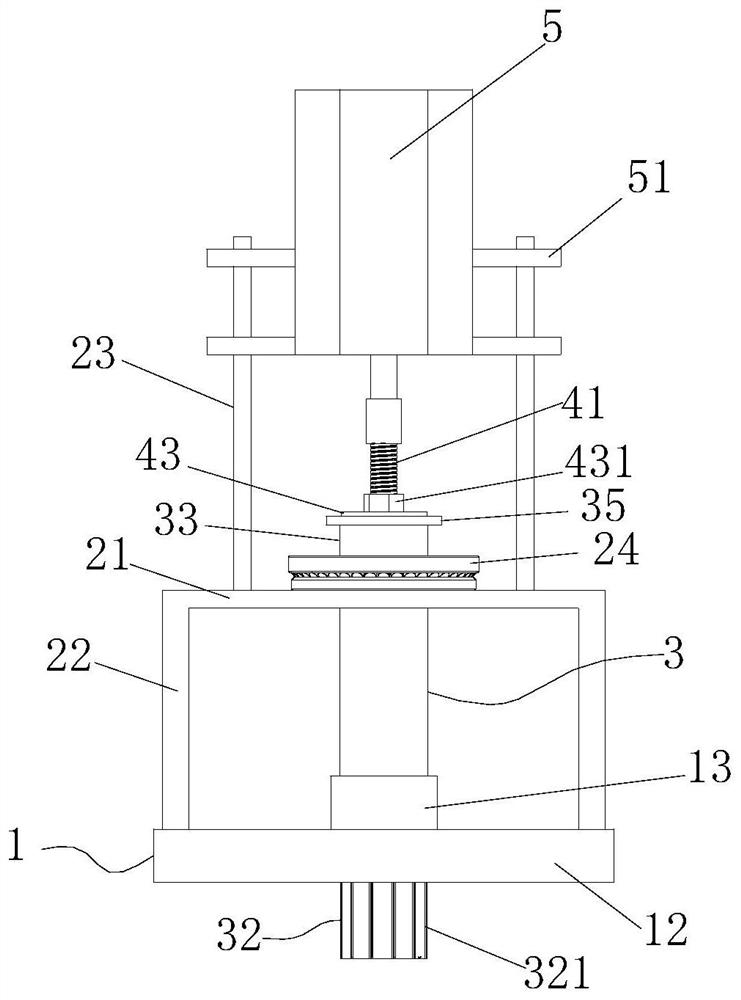

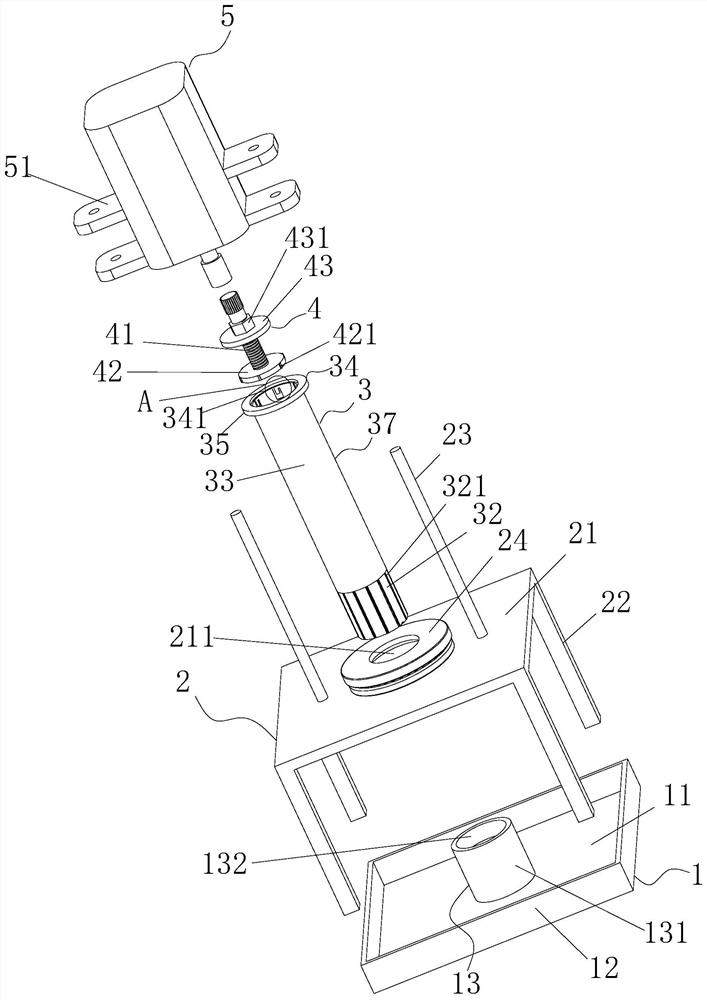

[0075] Please refer to Figure 1 to Figure 10 , the present invention proposes a hole repairing device for measuring the compactness of road surface by sand filling method, which includes a base 1 , a bracket 2 and a repairing cylinder 3 .

[0076] The base 1 is used to provide support for the entire hole repairing device. On the other hand, the base 1 is also used as a reference for digging and repairing holes. When the base 1 is used as a reference for digging a hole, the base 1 is pressed against the road surface to be dug, and then the hole is dug from the first circular hole 111 .

[0077] The bracket 2 is used to support the repairing cylinder 3 and the driving motor 5, and the repairing cylinder 3 is used to repair the formed soil hole.

[0078] Specifically, please refer to figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com