Blade hardness detection auxiliary clamp

A technology for auxiliary fixtures and blades, which is applied in the direction of measuring devices, strength characteristics, instruments, etc., can solve the problems of complex shape of precision forging blades, increase the difficulty of hardness detection, scrap parts, etc., achieve shortened detection time, compact structure, and low manufacturing cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in further detail below in conjunction with accompanying drawing:

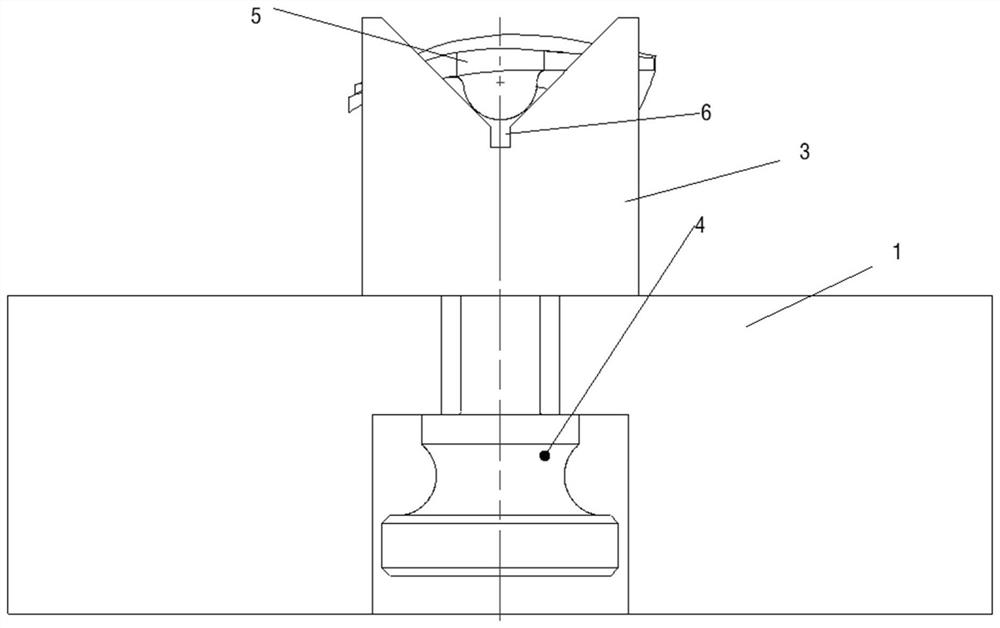

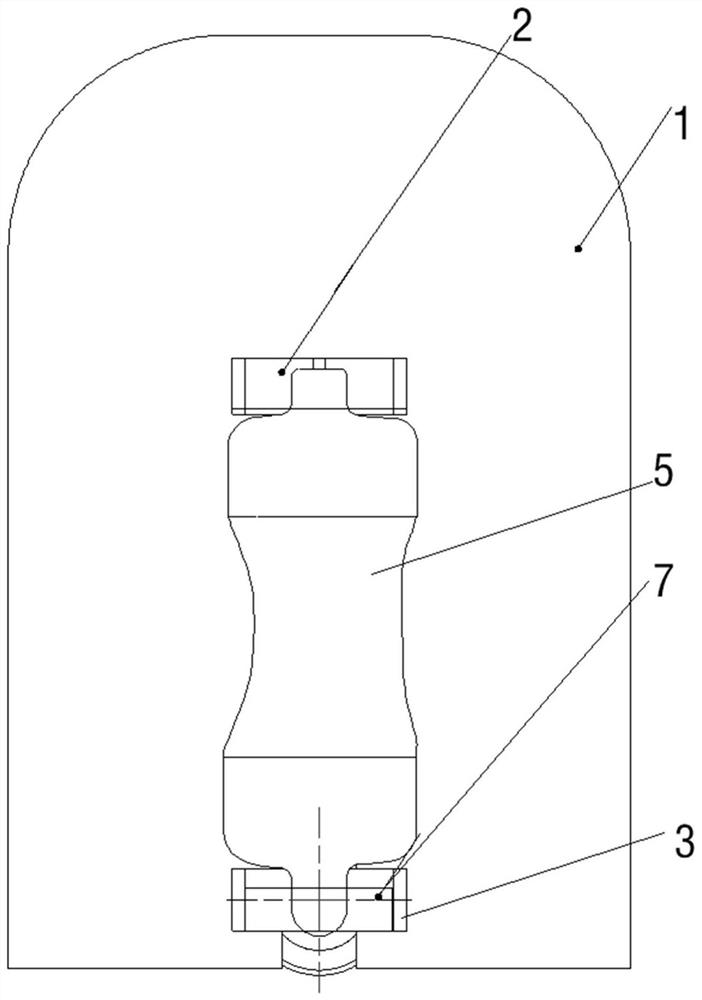

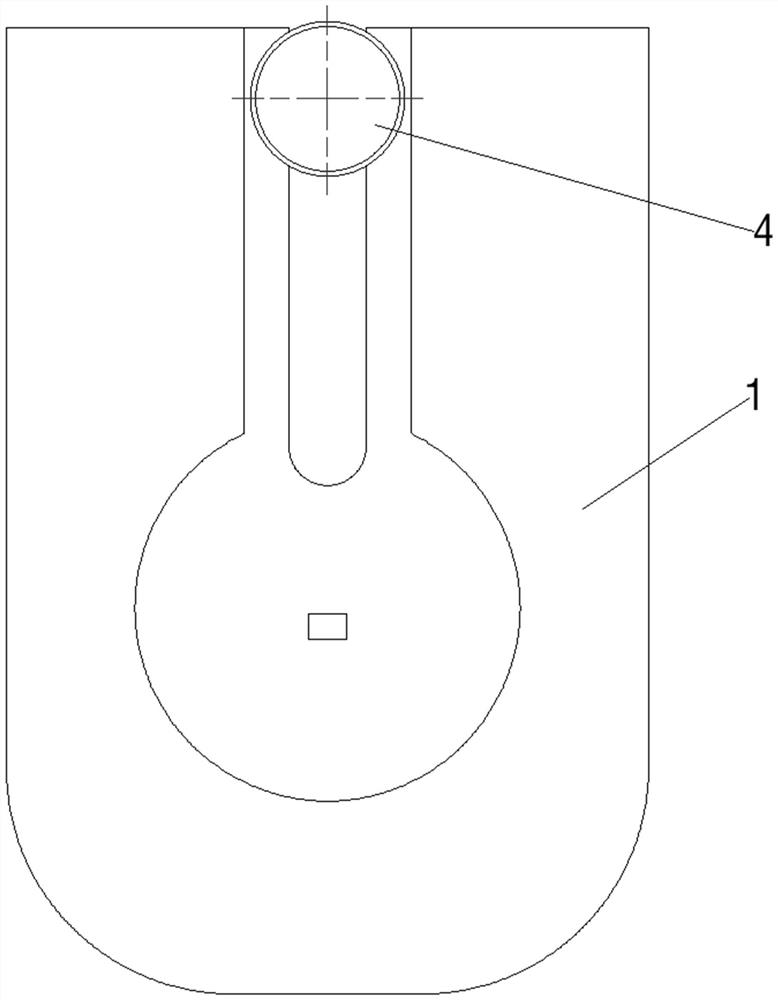

[0026] Such as Figure 1 to Figure 3 As shown, an auxiliary jig for blade hardness testing includes a support plate 1, a fixed block 2 and a sliding block 3, the support plate 1 is fixed on the turntable of the hardness machine, the fixed block 2 is fixed on the upper end of the support plate 1, and the support plate 1 is provided with chute, the sliding block 3 is set in the chute of the support plate 1, the fixed block 2 and the sliding block 3 are provided with positioning grooves, the center line of the positioning groove on the fixed block 2 and the sliding block 3 is aligned with the chute of the support plate 1 The centerlines lie on the same straight line. During use, fix the support plate 1 on the turntable of the hardness machine, and then select the fixed block 2 and the sliding block 3 of the appropriate positioning slot according to the specifications of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com