High-speed punching machine cutting mechanism and cutting method thereof

A technology of high-speed punching machine and power transmission mechanism, which is applied in the direction of punching machine, press machine, metal processing equipment, etc. It can solve the problems that the cutting head cannot be replaced, the transmission parts of the device are worn out, and the service life is not long, so as to achieve post-maintenance Low cost, stable force, energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

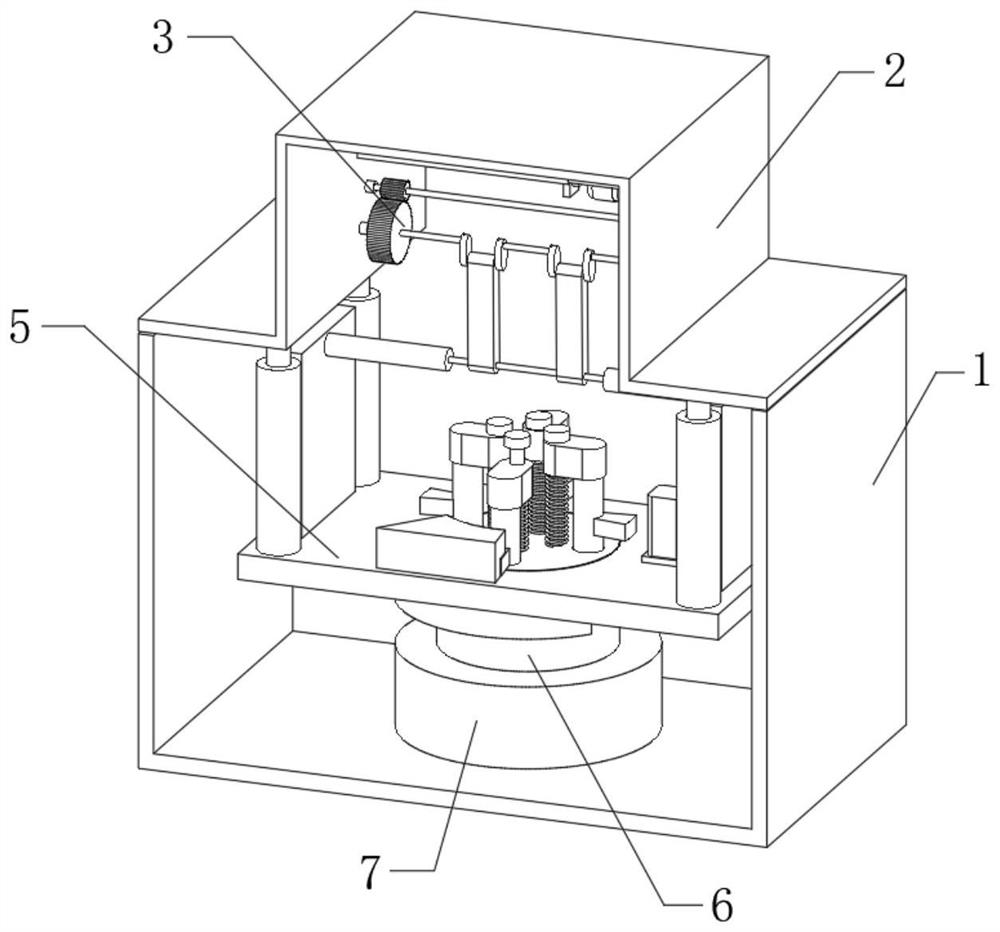

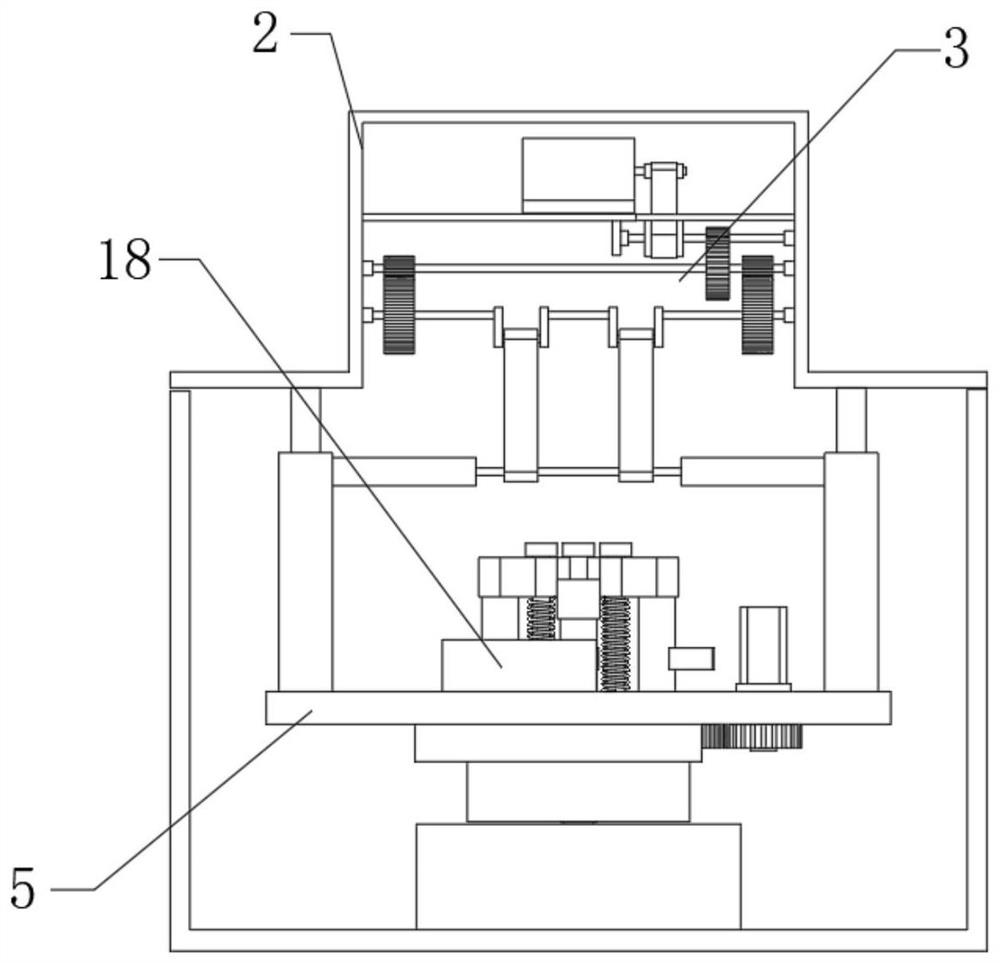

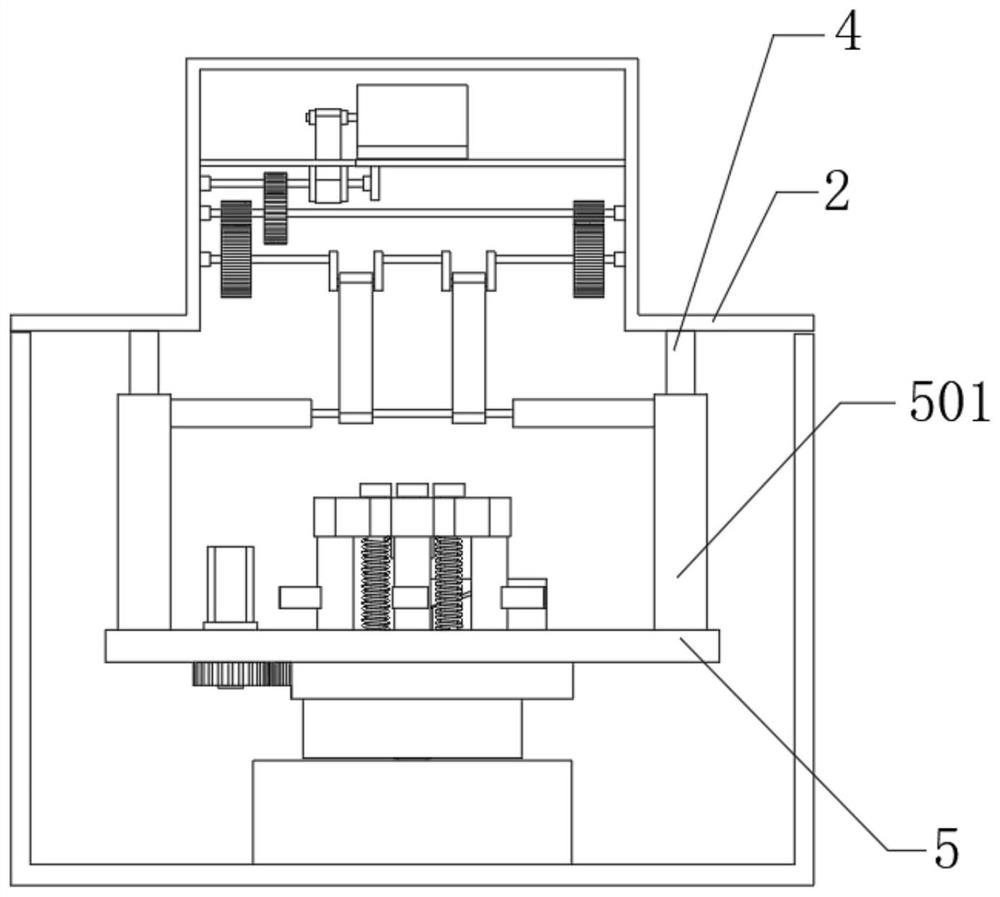

[0041] The embodiment of the present invention discloses a high-speed punch cutting mechanism, such as Figure 1-10 shown, including:

[0042] The bottom frame 1 of the high-speed punch press, the top frame 1 of the high-speed punch press bottom is fixedly connected with the top frame 2 of the high-speed punch press, the bottom of the top frame 2 of the high-speed punch press is provided with a power transmission mechanism 3, and the bottom of the power transmission mechanism 3 is connected with a lifting platform 5, the lifting platform 5 is rotatably connected with a cutting cylindrical base 6, the bottom of the cutting cylindrical base 6 is provided with a cutting head main body 14, and the bottom frame 1 of the high-speed punch press is provided with a lower support base 7;

[0043] The automatic replacement mechanism of the cutting head, the automatic replacement mechanism of the cutting head includes an outer toothed disc 8, the outer toothed disc 8 is fixedly connected ...

Embodiment 2

[0059] The embodiment of the present invention discloses a high-speed punch cutting mechanism, such as Figure 1-10 shown, including:

[0060] The bottom frame 1 of the high-speed punch press, the top frame 1 of the high-speed punch press bottom is fixedly connected with the top frame 2 of the high-speed punch press, the bottom of the top frame 2 of the high-speed punch press is provided with a power transmission mechanism 3, and the bottom of the power transmission mechanism 3 is connected with a lifting platform 5, the lifting platform 5 is rotatably connected with a cutting cylindrical base 6, the bottom of the cutting cylindrical base 6 is provided with a cutting head main body 14, and the bottom frame 1 of the high-speed punch press is provided with a lower support base 7;

[0061] The automatic replacement mechanism of the cutting head, the automatic replacement mechanism of the cutting head includes an outer toothed disc 8, the outer toothed disc 8 is fixedly connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com