A multifunctional wood processing system and method

A processing system and multi-functional technology, applied in the field of wood processing, can solve the problems of material confusion, waste of manpower and material resources, low processing efficiency, etc., and achieve the effect of avoiding material confusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

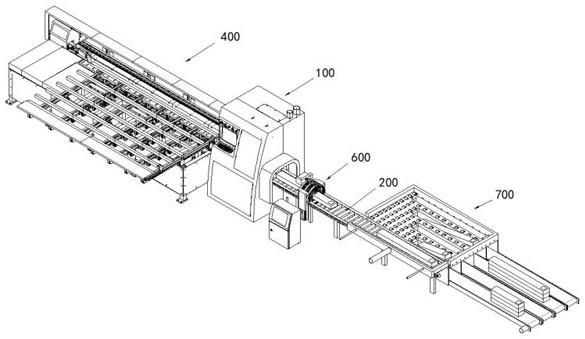

[0060] like figure 2 As shown, the multifunctional wood processing system of this embodiment includes a cutting mechanism 100, a material discharge conveying line 200, a coding mechanism 300, a feeding mechanism 400, a turning mechanism 600, and a material selection mechanism 700;

[0061] The feeding mechanism 400 is connected to the feeding end of the cutting mechanism 100, the discharging conveying line 200 is connected to the discharging end of the cutting mechanism 100, and the discharging conveying line 200 is a roller conveying line;

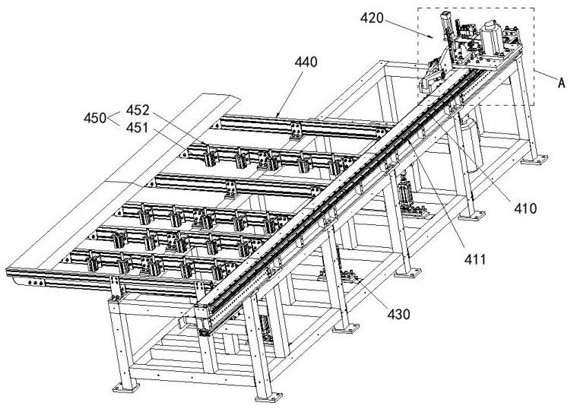

[0062] like image 3 and Figure 4 As shown, the feeding mechanism 400 includes a pushing rail 410, a feeder 420, a jacking mechanism 430, a conveying body 440 and a feeding controller 450, the pushing rail 410 is connected to the feeding end of the cutting mechanism 100, and the pushing The pusher 420 is located on the pusher track 410, the pusher 420 can move back and forth along the pusher track 410, the conveying body 440 is a conv...

Embodiment 2

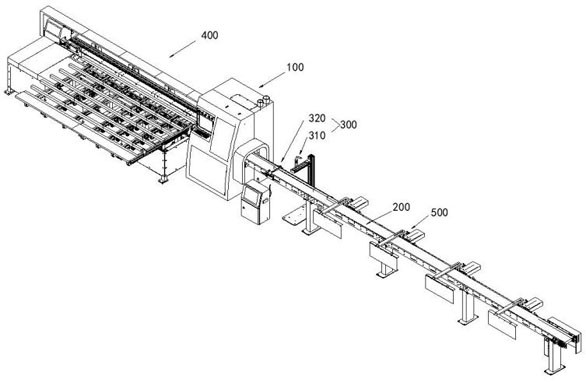

[0089] like figure 1As shown, the multifunctional wood processing system of this embodiment includes a cutting mechanism 100 , a discharging conveying line 200 , a coding mechanism 300 , a feeding mechanism 400 and a sorting mechanism 500

[0090] The feeding mechanism 400 is connected to the feeding end of the cutting mechanism 100, the discharging conveying line 200 is connected to the discharging end of the cutting mechanism 100, and the discharging conveying line 200 is a conveyor belt conveying line; A sensor 320, the printer 310 is located just above the discharge conveying line 200, the first sensor 320 is located on the discharge conveying line 200, the first sensor 320 is mainly used to detect whether there is cut wood arriving or about to arrive at the inkjet Below the device 310, after the first sensor 320 detects the wood on the discharge conveying line 200, it transmits a signal to the processor, and the processor sends an instruction to let the inkjet 310 spray t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com