Construction method for perforating and pipe penetrating of basement concrete wall

A technology of concrete wall and construction method, applied in the direction of pipes, artificial islands, water conservancy projects, etc., can solve problems such as water seepage, and achieve the effects of reliable use, simple and convenient construction, and improved anti-seepage effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

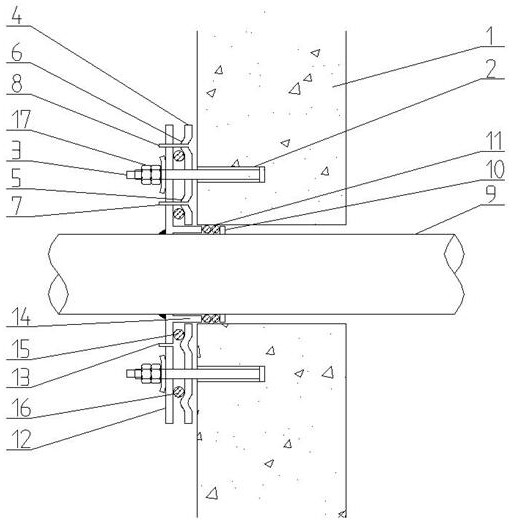

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0018] like figure 1 As shown, the construction method of the basement concrete wall perforation and pipe penetration in this specific embodiment includes the following steps:

[0019] (1) Carry out the pipeline perforation construction on the concrete wall 1. On the inner wall of the concrete wall 1, a plurality of screw mounting holes 2 are evenly spaced around the direction of the pipeline perforation centerline. The centerline direction of the screw mounting holes 2 and the pipeline The direction of the center line of the perforation is parallel, and the inner wall of the concrete wall 1 and the position around the pipe perforation are ground and rough, and the rough wall after grinding and the screw mounting hole 2 are cleaned. A mounting screw 3 arranged on the same centerline as the screw mounting hole 2 is implanted in the middle;

[0020] (2) Obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com