Beam and slab cast-in-place concrete partition system

A concrete, cast-in-place technology, applied in the direction of formwork/formwork/work frame, on-site preparation of building components, connection of formwork/formwork/work frame, etc. Poor concrete effect, easy to be washed away by concrete and other problems, to achieve the effect of easy disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

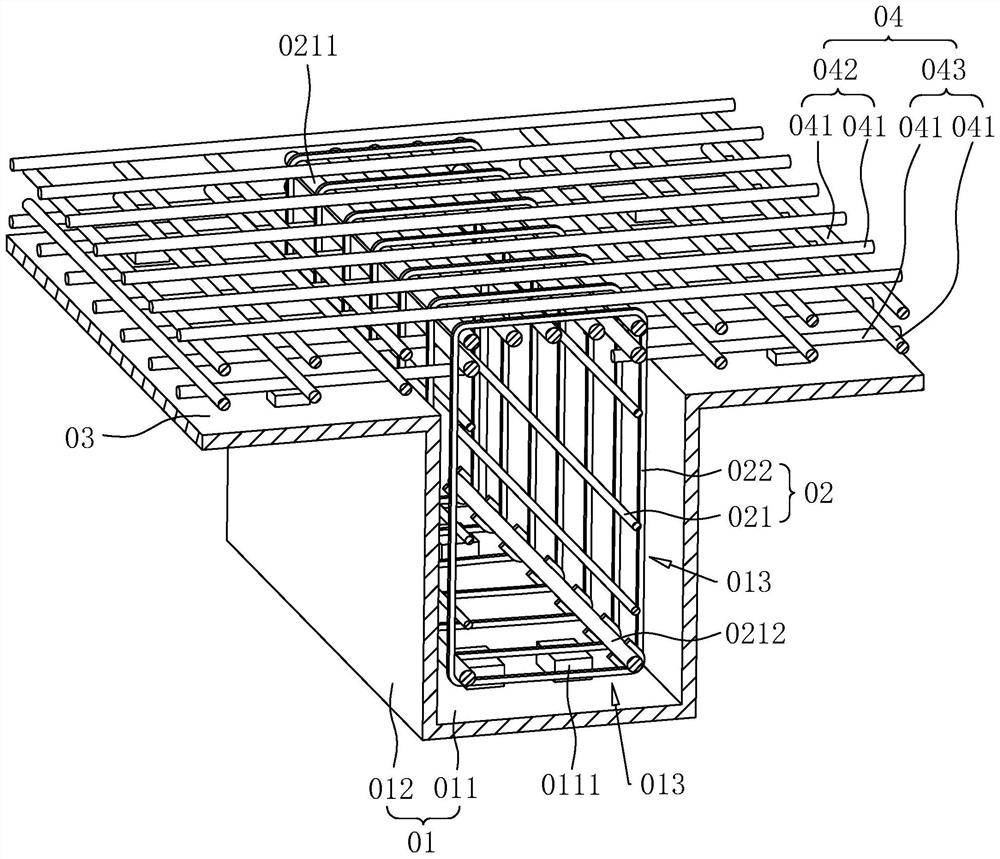

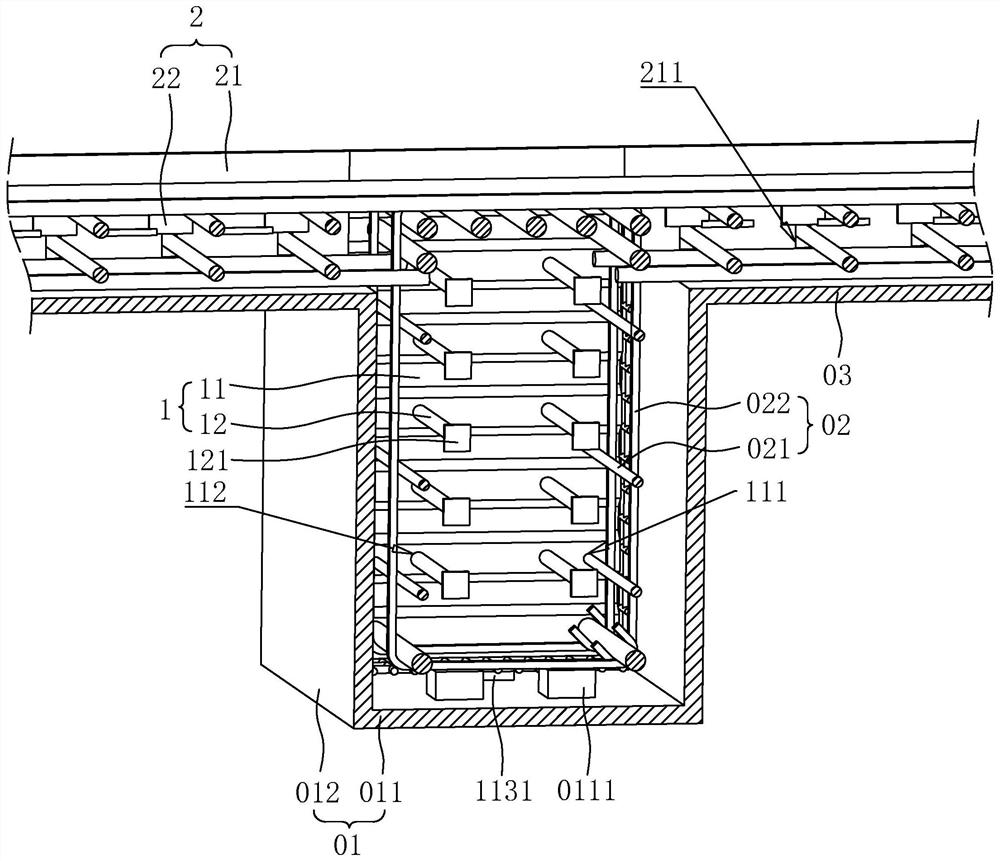

[0061] refer to figure 2 , a beam-slab cast-in-place concrete partition system includes a beam sealing member 1 and a plate sealing member 2 .

[0062] refer to figure 2 , The beam closure member 1 includes a partition plate 11 and a shear bar 12 .

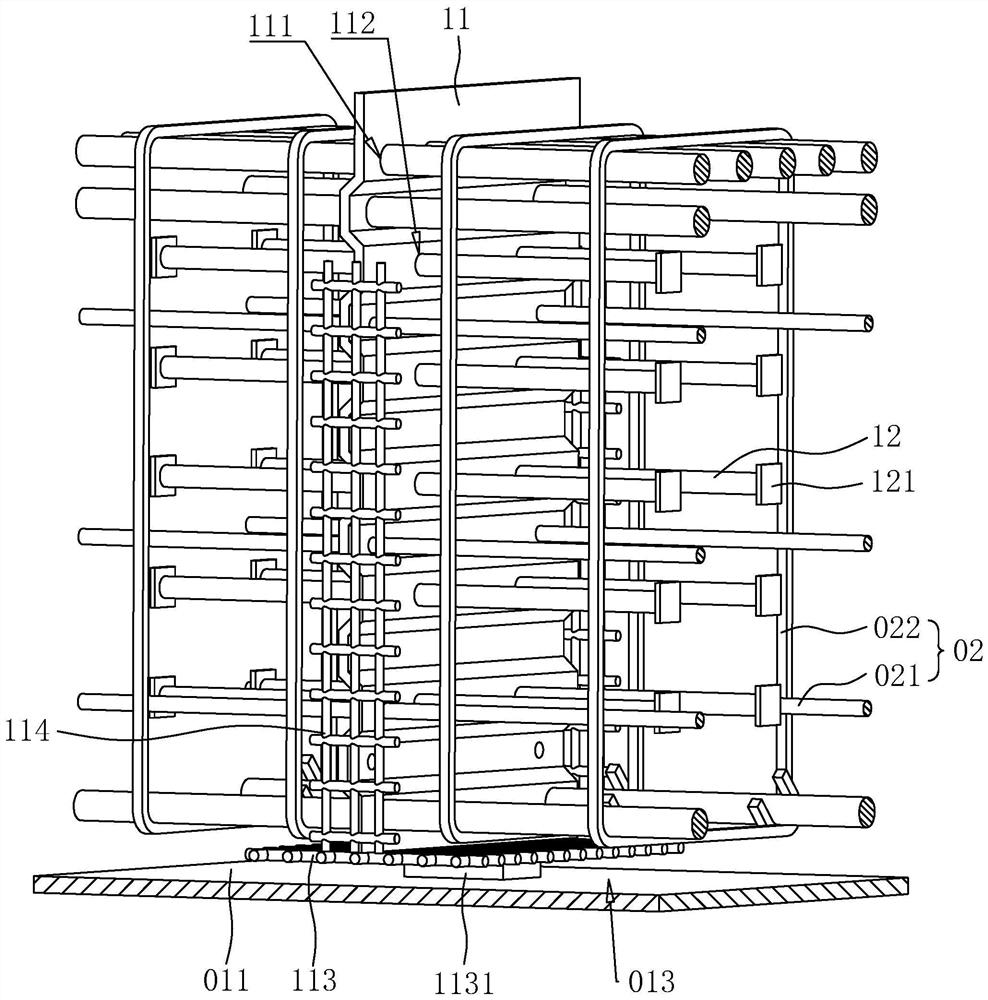

[0063] refer to figure 2 and image 3 , the partition 11 is arranged on the beam reinforcement skeleton 02. In this embodiment, the partition 11 is a concave-convex plate with a rectangular shape, and the length direction of the partition 11 is arranged along the vertical direction. In other embodiments, the partition 11 can be Inclined setting; in this embodiment, the partition 11 is a profiled steel plate, and in other embodiments, the partition 11 can be a hard seamless board such as a corrugated steel plate or a corrugated board; the partition 11 is located between two stirrups 022 , a plurality of first through holes 111 are opened on the partition 11, and the first through holes 111 are used for passing through the lo...

Embodiment 2

[0078] The difference between this embodiment and Embodiment 1 lies in that the anchoring structure 121 is different, the fixing method of the first steel wire mesh 113 is different, the structure of the beam blocking part 1 is different, and the structure and fixing method of the plate blocking part 2 are different.

[0079] refer to Figure 8 , in the present embodiment, the anchoring structure 121 is a nut, and each two ends of each shearing steel bar 12 tendons are threadedly connected with an anchoring structure 121; welding.

[0080] refer to Figure 8 , in this embodiment, the end of the partition 11 away from the bottom template 011 is located on the side of the top row of ribs 0211 close to the bottom template 011, and the end of the partition 11 away from the bottom template 011 is in contact with the top row of ribs 0211, and the partition 11 The end close to the bottom template 011 is located on the side of the bottom row of ribs 0212 away from the bottom templat...

Embodiment 3

[0095] The difference between this embodiment and Embodiment 2 is that the structure of the partition 11 is different, the structure of the blocking plate 5 is different, the connection mode of the blocking plate 5 and the partition 11 is different, the fixing method of the first steel wire mesh 113 is different, and the movable The structure of piece 22 is different.

[0096] refer to Figure 12 , in this embodiment, the partition 11 is a concave-convex plate with several bumps 115 and several grooves 116 on the surface of the partition, the basic plate shape of the partition 11 is a rectangular steel plate, and the two board surfaces of the partition 11 A plurality of rectangular block-shaped bumps 115 are uniformly connected, and a groove 116 with a rectangular port is opened at the position where the partition 11 is provided with the bump 115. The bump 115 and the groove 116 at the same position on the partition 11 are located On the board walls on different sides, a groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com