Concrete gap repairing and anti-seepage treatment method

A treatment method and anti-leakage technology, which is applied in the direction of building maintenance, construction, building construction, etc., can solve the problems of reduced life, easy leakage, corrosion damage, etc., and achieve the effect of improving the construction effect and improving the anti-leakage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

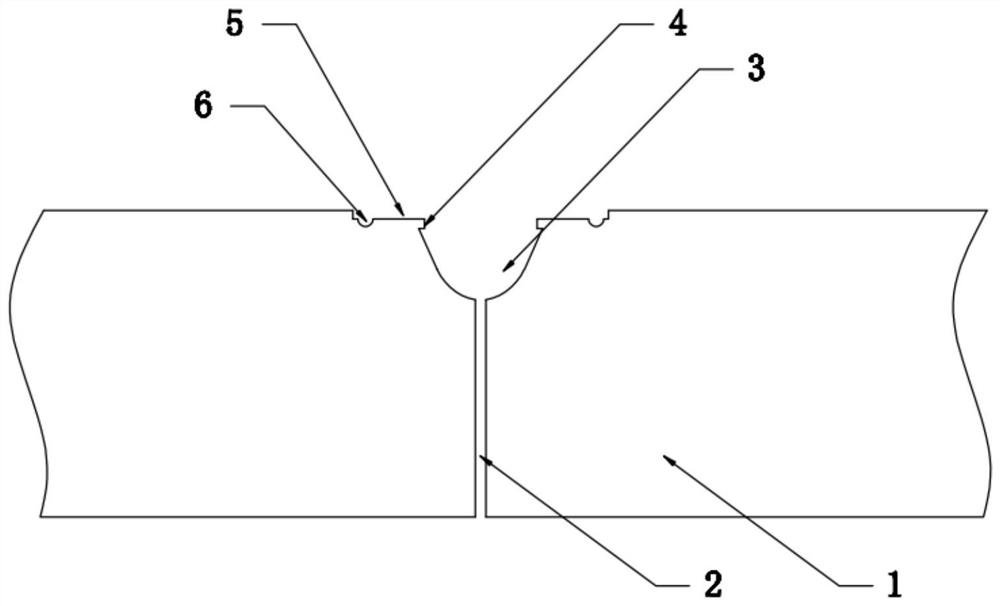

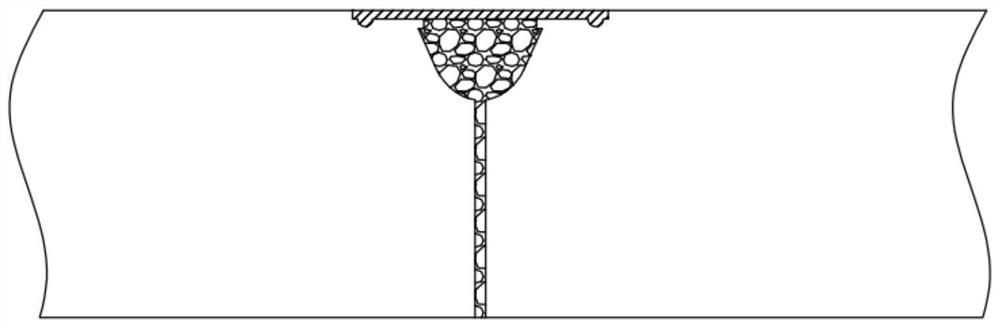

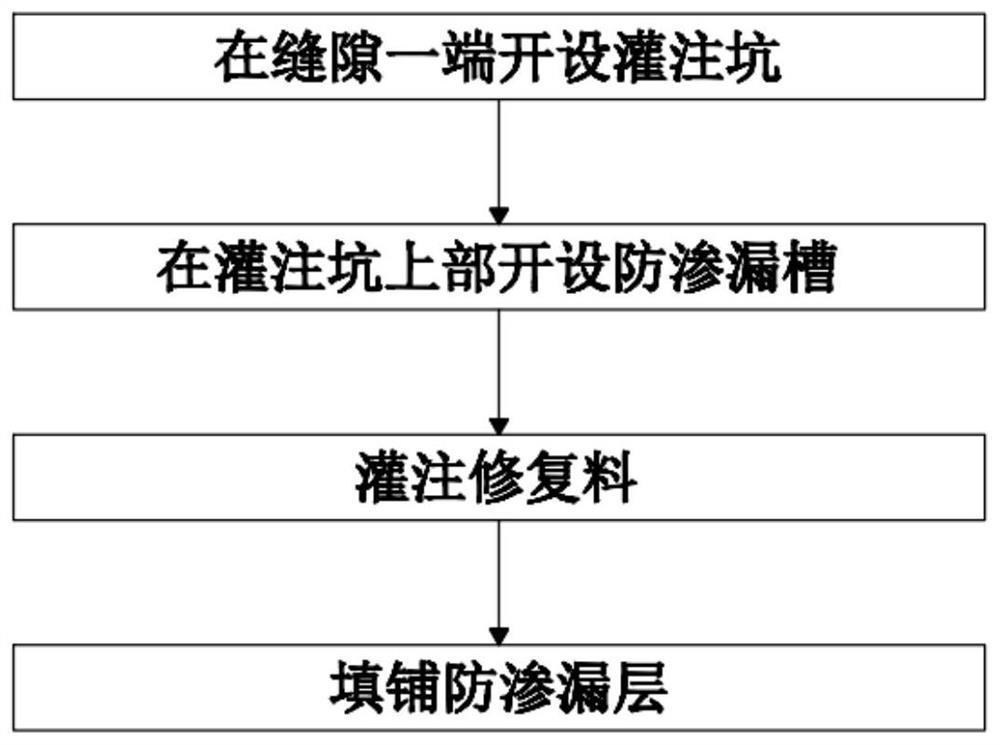

[0029] see Figure 1-3 , the present invention provides a technical solution: a concrete gap repair and anti-leakage treatment method, the concrete steps of the concrete gap repair and anti-leakage treatment method are as follows:

[0030] S1 Set up a pouring pit 3 at one end of the gap 2: set up a pouring pit 3 between the retarded concrete structures 1 on both sides, the pouring pit 3 is located at the upper end of the gap 2 between the retarded concrete structures 1 on both sides, and the pouring pit 3 is a symmetrical arc Shape, a sealing flange 4 is left on the upper inner wall of the filling pit 3, the sealing flange 4 is a block protruding to the inside of the filling pit 3, and the sealing flange 4 intersects with one end of the side line of the filling pit 3;

[0031] S2 Set up an anti-seepage groove 5 on the upper part of the pouring pit 3: set up an anti-seepage groove 5 on the outer surface of the retarded concrete structure 1, the anti-seepage groove 5 is located ...

Embodiment 2

[0040] The specific steps of the concrete gap repair and anti-seepage treatment method are as follows:

[0041] S1 Set up a pouring pit 3 at one end of the gap 2: set up a pouring pit 3 between the retarded concrete structures 1 on both sides, the pouring pit 3 is located at the upper end of the gap 2 between the retarded concrete structures 1 on both sides, and the pouring pit 3 is a symmetrical arc Shape, a sealing flange 4 is left on the upper inner wall of the filling pit 3, the sealing flange 4 is a block protruding to the inside of the filling pit 3, and the sealing flange 4 intersects with one end of the side line of the filling pit 3;

[0042] S2 Set up an anti-seepage groove 5 on the upper part of the pouring pit 3: set up an anti-seepage groove 5 on the outer surface of the retarded concrete structure 1, the anti-seepage groove 5 is located on the side of the pouring pit 3 away from the gap 2, and the anti-seepage groove 5. The positions between the pouring pits 3 ar...

Embodiment 3

[0051] The specific steps of the concrete gap repair and anti-seepage treatment method are as follows:

[0052] S1 Set up a pouring pit 3 at one end of the gap 2: set up a pouring pit 3 between the retarded concrete structures 1 on both sides, the pouring pit 3 is located at the upper end of the gap 2 between the retarded concrete structures 1 on both sides, and the pouring pit 3 is a symmetrical arc Shape, a sealing flange 4 is left on the upper inner wall of the filling pit 3, the sealing flange 4 is a block protruding to the inside of the filling pit 3, and the sealing flange 4 intersects with one end of the side line of the filling pit 3;

[0053] S2 Set up an anti-seepage groove 5 on the upper part of the pouring pit 3: set up an anti-seepage groove 5 on the outer surface of the retarded concrete structure 1, the anti-seepage groove 5 is located on the side of the pouring pit 3 away from the gap 2, and the anti-seepage groove 5. The positions between the pouring pits 3 ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The maximum diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com