Fine particle cross-flow characteristic research method based on ore rock particle system structural characteristics

A technology of fine particles and system structure, applied in particle and settlement analysis, solid dispersion analysis, instruments, etc., can solve the problems of invisible and lack of quantitative analysis in the flow process of fine particles of caving ore rocks, and achieve simple operation and accurate experimental process. visible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

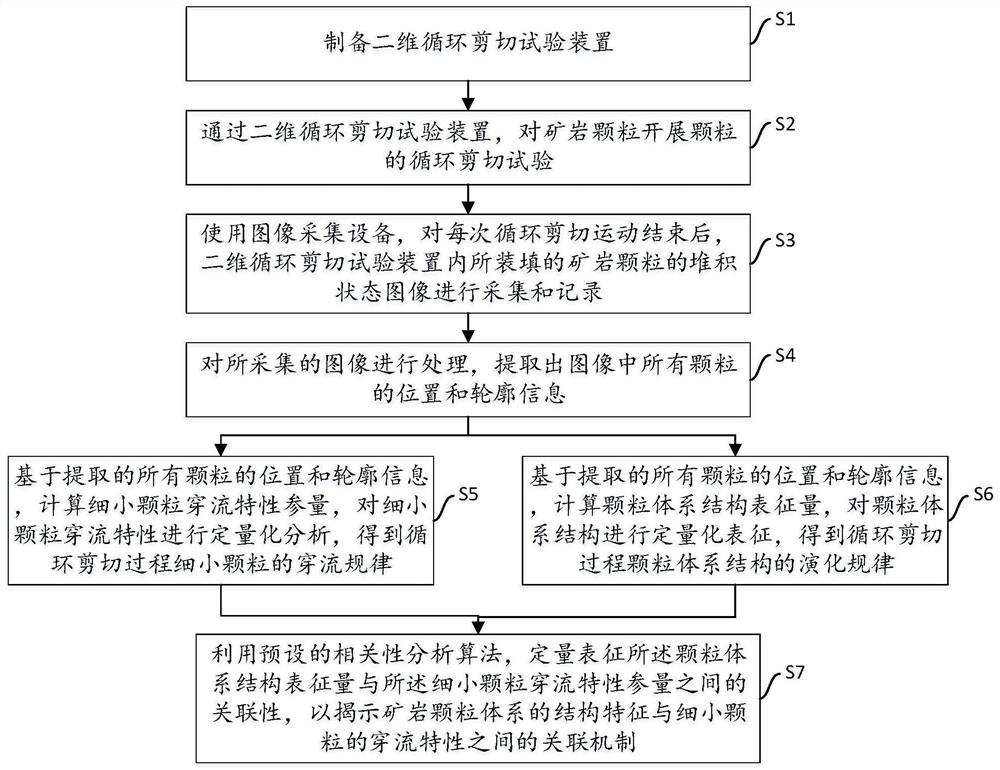

[0061] This embodiment provides a method for researching the through-flow characteristics of fine particles based on the structural characteristics of ore-rock particles. The execution flow of the research method for the through-flow characteristics of fine particles is as follows figure 1 shown, including the following steps:

[0062] S1, preparing a two-dimensional cyclic shear test device;

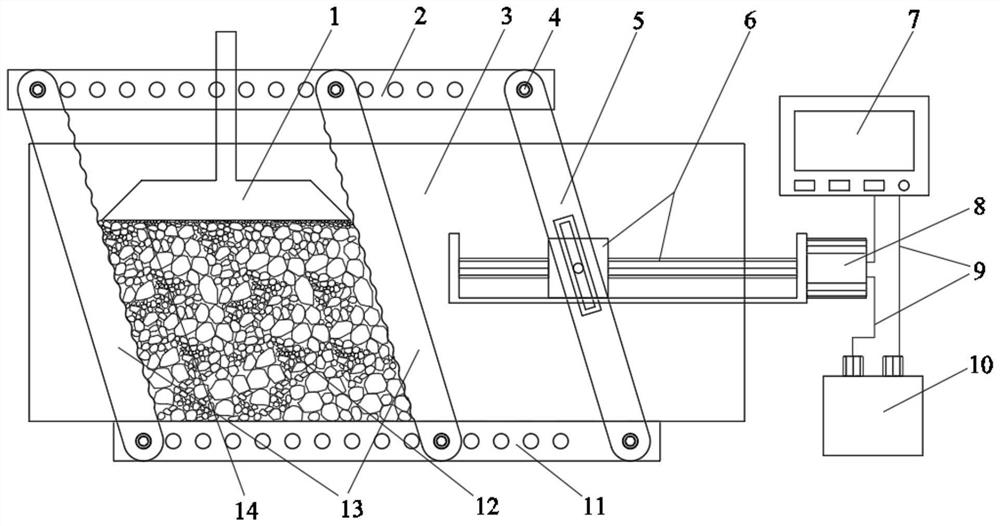

[0063] Specifically, in this example, the prepared two-dimensional cyclic shear test device is as figure 2 As shown, it consists of three parts, namely: shearing mechanism, driving mechanism and control mechanism 7; wherein,

[0064] The shearing mechanism includes an upper parallel plate 2, a lower parallel plate 11, two shearing side plates...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com