Modular PCB connecting structure and charging base thereof

A PCB board and connection structure technology, applied in the direction of connection, support structure installation, and parts of connection devices, etc., can solve the problems of complex assembly process of employees, unfavorable batch automatic production, and influence on the use of electric vehicles, etc., to achieve convenient component structure design , Guarantee the effect of trouble-free use time and stable assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

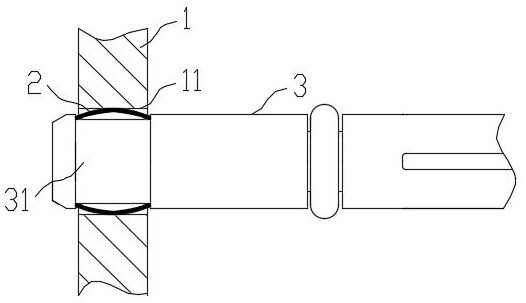

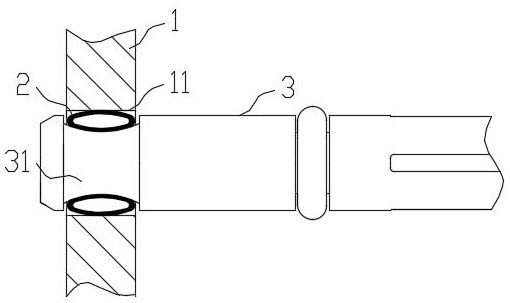

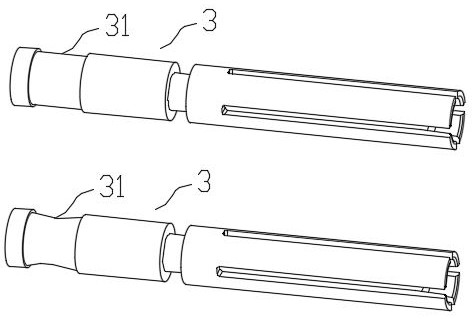

[0028] like Figure 1-3 It is a schematic diagram of the structure of the present invention, a modular PCB board connection structure, including a PCB board 1, an elastic ring 2 and a terminal 3, the PCB board 1 is provided with a number of conductive through holes 11, and the end of the terminal 3 is provided. There is an installation groove 31 in the part, and the elastic ring 2 is sleeved in the installation groove 31. The maximum outer diameter of the elastic ring 2 is larger than the diameter of the current hole 11 and is elastic. The maximum outer diameter of the elastic ring 2 The surface abuts the electrification hole 11 .

[0029] The thickness of the PCB board 1 can be more than 3mm, and the side wall is plated with gold.

[0030] like Figure 4-5 As shown, the charging stand including the modular PCB board connection structure includes a rear cover 6 and a socket body 5. The socket body 5 is provided with a PCB board mounting surface 51, and the right side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com