Application method of wheat flour gelatinized juice in cigar fermentation

A technology of wheat flour and application method, applied in application, tobacco, tobacco treatment and other directions, can solve the problems of reducing irritation, poor flavor enhancement effect, and low number of microbial colonies on the surface of tobacco leaves, and achieves the effect of increasing the number and enhancing the flavor and aroma.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

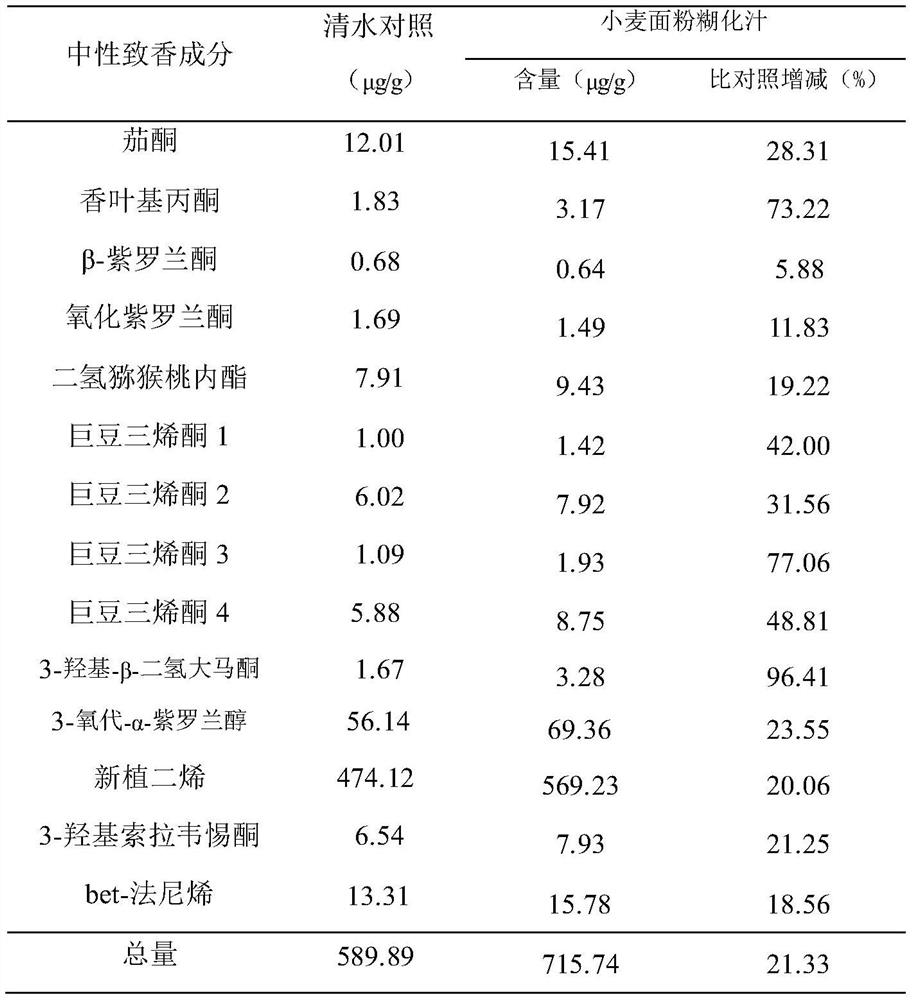

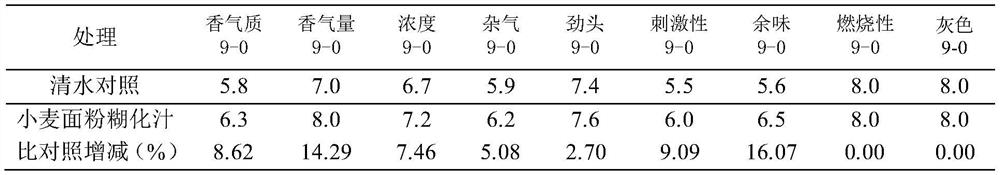

Examples

Embodiment 1

[0028] An application method of wheat flour gelatinized juice in cigar tobacco fermentation, comprising the following steps:

[0029] S1. Frying the wheat flour for the first time until the color of the wheat flour is yellow. Specifically, put the wheat flour into an iron pan and fry it for 2 to 3 minutes at a temperature of 100°C to 120°C in the pot. During the frying process, stir fry the wheat flour continuously so that the wheat flour is heated evenly , fry until the color of wheat flour is yellow.

[0030] S2, frying the yellow wheat flour in step S1 for the second time until the color of the wheat flour is brown. Specifically, continue to stir-fry for 1-2 minutes with a temperature of 180°C-200°C in the pot. During the frying process, stir-fry the wheat flour continuously so that the wheat flour is heated evenly, and stir-fry until the color of the wheat flour is brown.

[0031] S3, frying the brown wheat flour in step S2 for the third time until the wheat flour is in...

Embodiment 2

[0036] An application method of wheat flour gelatinized juice in cigar tobacco fermentation, comprising the following steps:

[0037] Step S1. Select 2kg of Dexue No. 1 middle grade two tobacco leaves provided by Deyang Tobacco Company in Sichuan Province, 0.2kg of wheat flour, put 0.2kg of wheat flour into an iron pot, and use a small fire with a temperature of 100°C to 105°C in the pot Stir-fry for 3 minutes, keep stirring so that the wheat flour is heated evenly, and the color of the wheat flour turns yellow.

[0038]Step S2, stir-fry for 2 minutes at medium heat with an inner temperature of 180° C. to 185° C., stirring continuously so that the wheat flour is heated evenly, and the color of the wheat flour turns brown.

[0039] Step S3, stir-fry for 3 minutes at a low heat with a temperature of 100°C to 105°C in the pot, and stir fry continuously so that the wheat flour is heated evenly, and the wheat flour turns brown and coagulates into small noodle pieces.

[0040] Step...

Embodiment 3

[0044] An application method of wheat flour gelatinized juice in cigar tobacco fermentation, comprising the following steps:

[0045] Step S1. Select 2.4kg of Dexue No. 3 middle secondary tobacco leaves provided by Deyang Tobacco Company in Sichuan Province and 0.2kg of wheat flour. Stir-fry on high heat for 2.5 minutes, keep stirring so that the wheat flour is heated evenly, and the color of the wheat flour turns yellow.

[0046] Step S2, stir-fry for 1.5 minutes at medium heat with an inner temperature of 185° C. to 190° C., stirring continuously so that the wheat flour is heated evenly, and the wheat flour turns brown in color.

[0047] Step S3, then stir-fry for 2.5 minutes at a low heat with an internal temperature of 105° C. to 110° C., stirring continuously so that the wheat flour is heated evenly, and the wheat flour turns brown and coagulates into small noodle pieces.

[0048] Step S4, transfer the small brown noodles to the prepared hot water pot at 45°C-50°C; boil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com