Automatic forging and knocking device for manufacturing iron pictures

An iron painting and magnet technology, which is applied in the field of automatic forging and knocking devices, can solve the problems of time-consuming and laborious forging work and lack of consistency, and achieve the effects of improving work efficiency, improving forging effect and ensuring product consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with examples, which are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

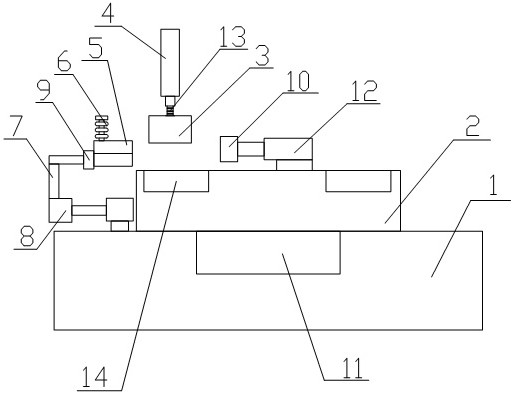

[0013] Such as figure 1 As shown, this embodiment provides an automatic forging device for making iron paintings, including a base 1, on which a forging anvil 2 is arranged, and the forging anvil 2 is arranged on the upper end of the base 1, and the forging A forging head 3 is arranged on the top of the cutting board 2, and a forging motor 4 is arranged on the upper end of the forging head 3, and the power is provided for the forging head 3 through the forging motor 4, and a fixed clip 5 is arranged beside the forging cutting board 2 , the fixed clip 5 is driven and clamped by the fixed spring 6 provided at the rear end, the rear end of the fixed clip 5 is provided with a displacement rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com