Collet chuck type clamping device

A technology of clamping device and collet, which is applied in the direction of positioning device, clamping, support, etc., can solve the problems of cumbersome operation, low precision, high price, etc., achieve convenient installation and disassembly, improve installation efficiency, and reduce stress damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

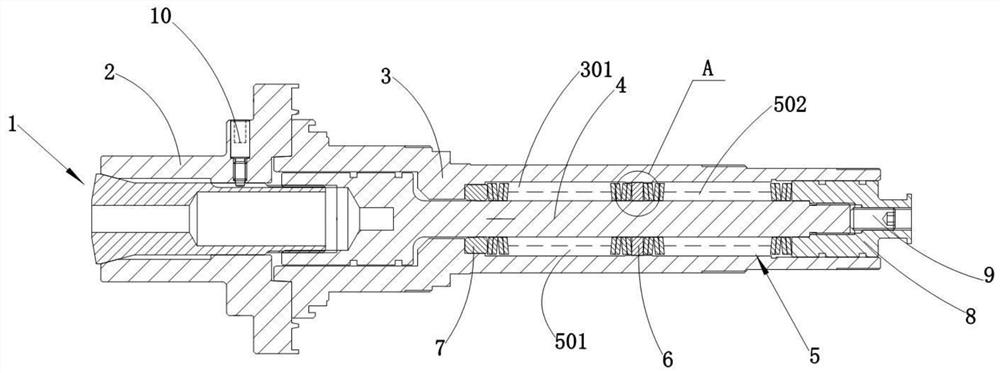

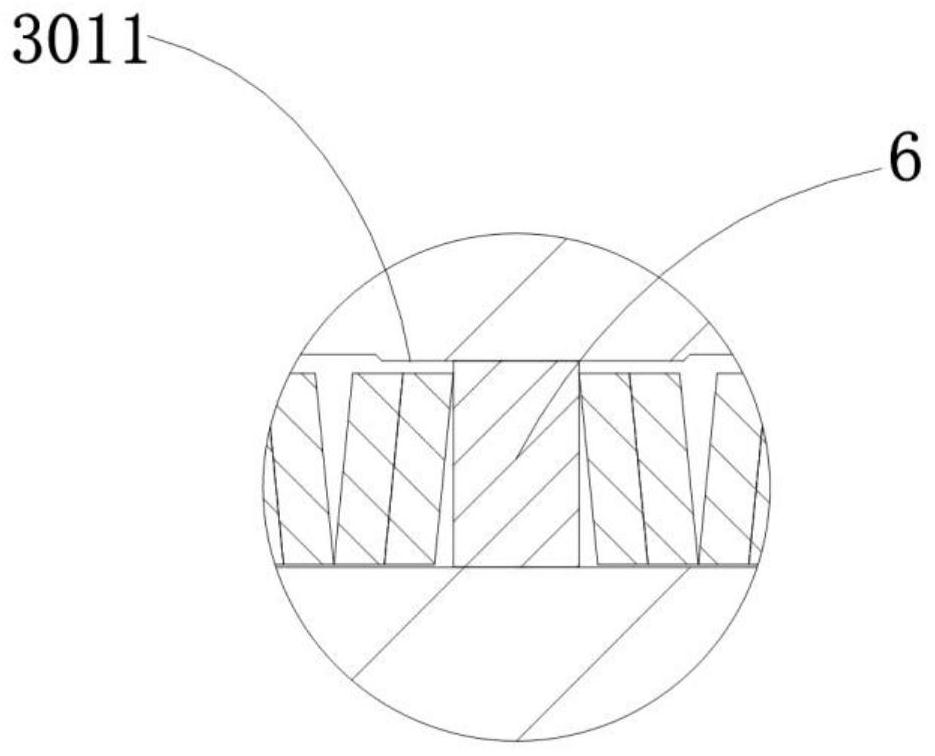

[0032]A collet-type clamping device, including a handle 2, a collet 1, and a broach device, the broach device includes a shaft core 3, at least one positioning spacer 6, a first disc spring assembly 501, The second disc spring assembly 502, a positioning washer 7, pull rod 4, pressure sleeve 8 and top wire 9, the head end of the collet 1 is inserted in the tail end of the knife handle 2 with interference, and the knife handle 2 is There are positioning pins in the radial direction, the tail end of the shaft core 3 is inserted in the head end of the handle 2 with interference, the shaft core 3 is provided with an axially penetrating cavity 301, and the pull rod 4 is movable through Set in the cavity 301, the tail end of the pull rod 4 is threadedly connected with the head end of the collet 1, and the head end of the pull rod 4 is threadedly connected with the tail end of the pressure sleeve 8, and the pressure sleeve 8 is arranged on the shaft core In the cavity 301 of 3, the f...

Embodiment 2

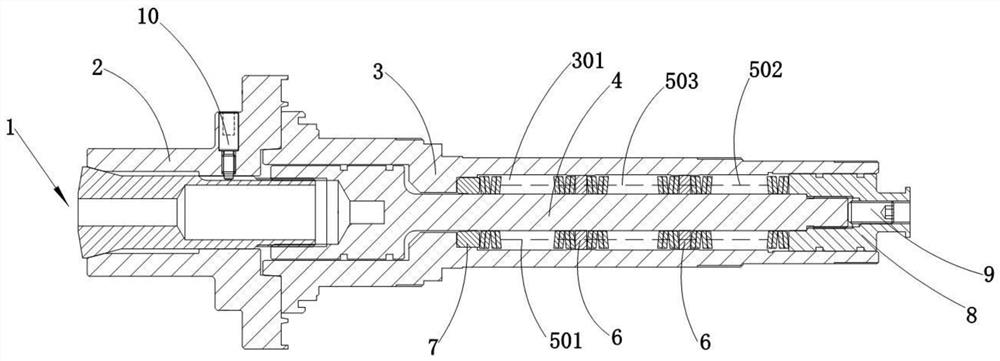

[0037] A collet-type clamping device, including a handle 2, a collet 1, and a broach device, the broach device includes a shaft core 3, two positioning spacers 6, a first disc spring assembly 501, a second Two disc spring assemblies 502, a third disc spring assembly 503, a positioning washer 7, a pull rod 4, a pressure sleeve 8 and a top screw 9, the head end of the collet 1 is inserted in the tail end of the handle 2 with interference, The knife handle 2 is provided with positioning pins in the radial direction, the tail end of the shaft core 3 is inserted in the head end of the knife handle 2 with interference, and the shaft core 3 is provided with a cavity 301 axially penetrating, The pull rod 4 is movably installed in the cavity 301, the tail end of the pull rod 4 is threadedly connected to the head end of the collet 1, the head end of the pull rod 4 is threaded to the tail end of the pressure sleeve 8, and the pressure sleeve 8 is threadedly connected. The sleeve 8 is set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com