Downward folding type carton pasting machine paper separator

A paper separation and box gluing technology, applied in paper/cardboard containers, containers, papermaking, etc., can solve the problems of not being able to automatically complete the stacking of multiple cartons, low degree of automation, and low work efficiency, so as to reduce the phenomenon of scattering , high degree of automation, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

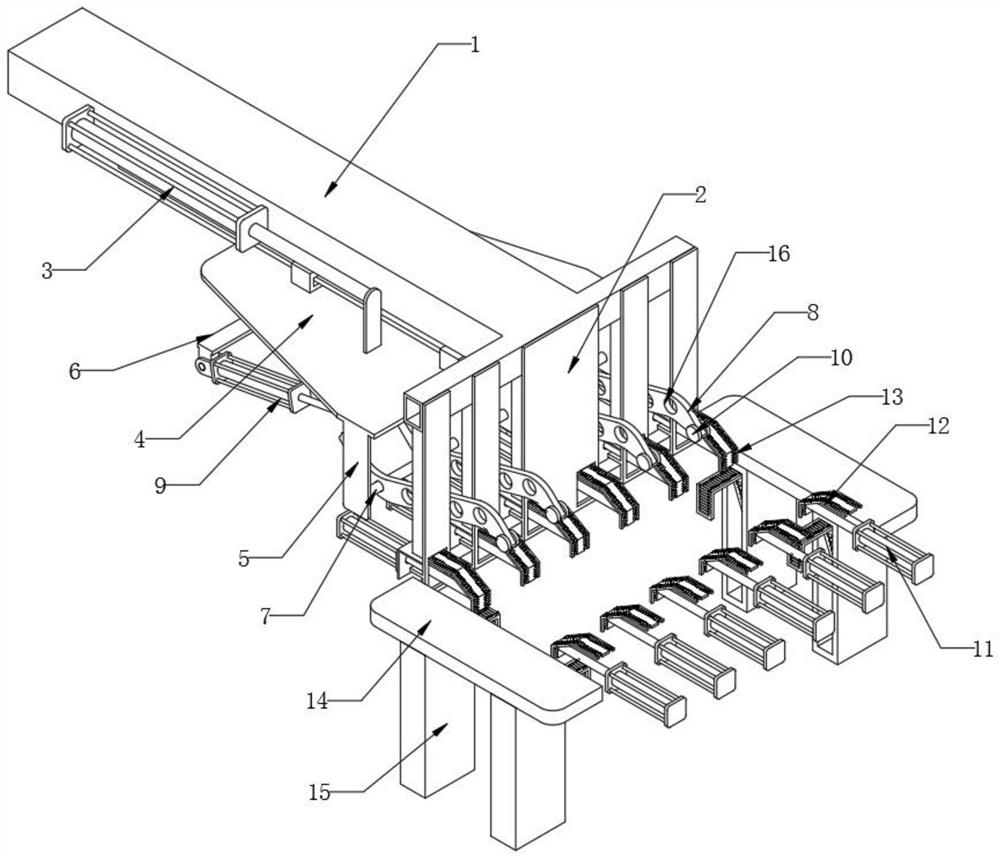

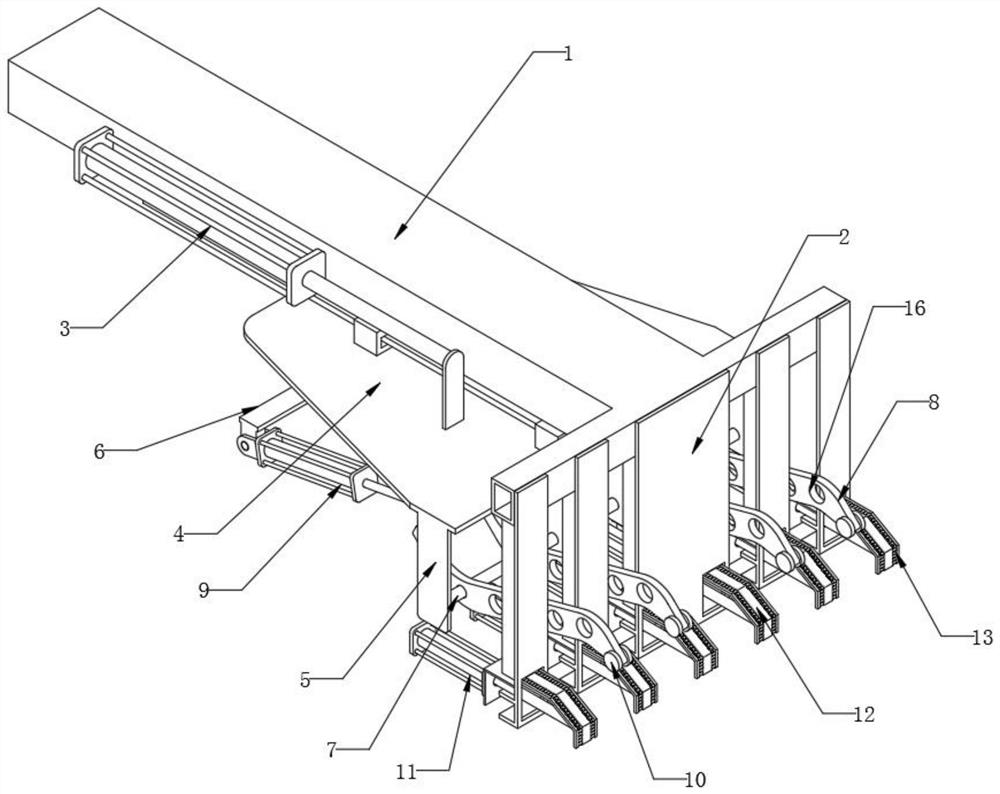

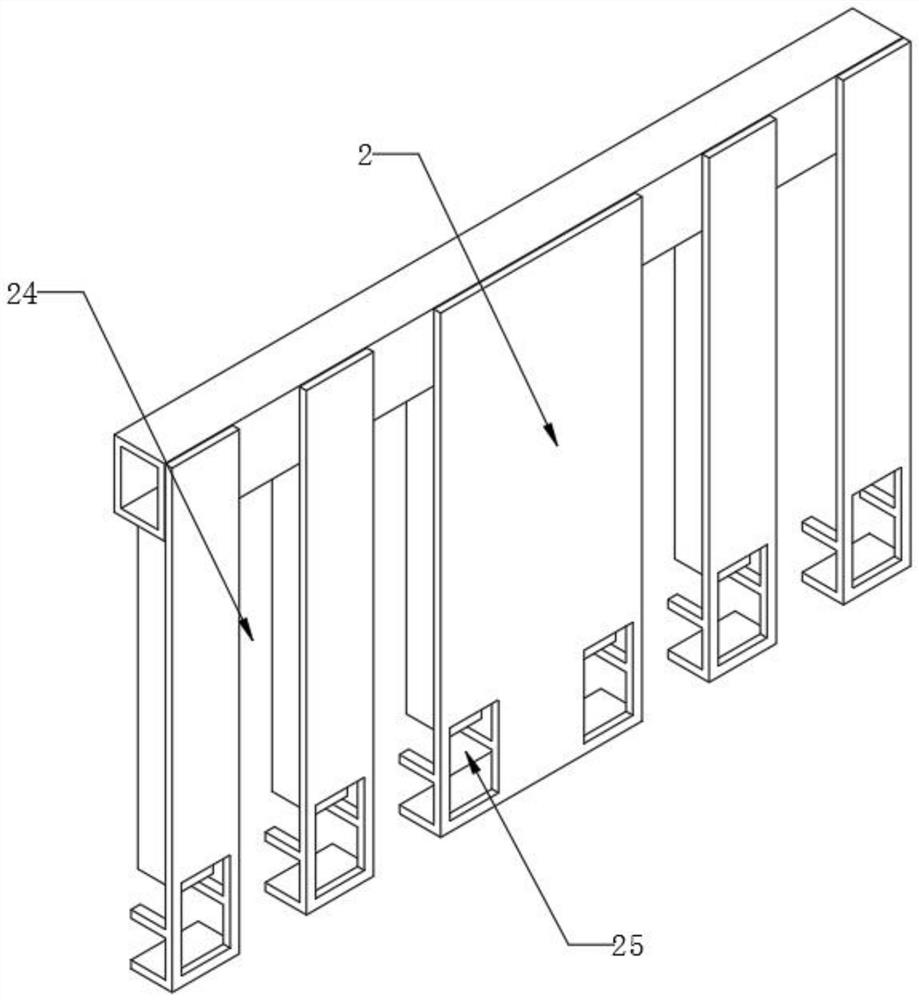

[0039] see Figure 1-6 As shown, a fold-down folder gluer paper separator includes a load-bearing beam 1 and two sets of telescopic load-bearing mechanisms. The front end of the load-bearing beam 1 is fixed with a cardboard 2, and the cardboard 2 is located at one end of the carton feeding conveyor belt, and Located at the upper end of the carton discharge conveyor belt;

[0040] One group of telescopic load-bearing mechanisms is fixedly connected to the rear end of the cardboard 2, another group of telescopic load-bearing mechanisms is arranged opposite to it, and another group of telescopic load-bearing mechanisms can be fixed on the carton feeding conveyor belt;

[0041] When the carton fed by the carton feeding conveyor belt is separated from the carton feeding conveyor belt, it will continue to move in the direction close to the cardboard stopper 2 due to the influence of inertia, until one end of the carton contacts the cardboard stopper 2 and is restricted by the cardbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com