Automatic box covering machine

A box cover machine, automatic technology, applied in the direction of container manufacturing machinery, box production operations, paper/cardboard containers, etc., can solve the problems of unstable performance of automatic box cover machine, increased workload of operators, unfavorable application and operation, etc. Achieve the effect of compact structure, high failure rate and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

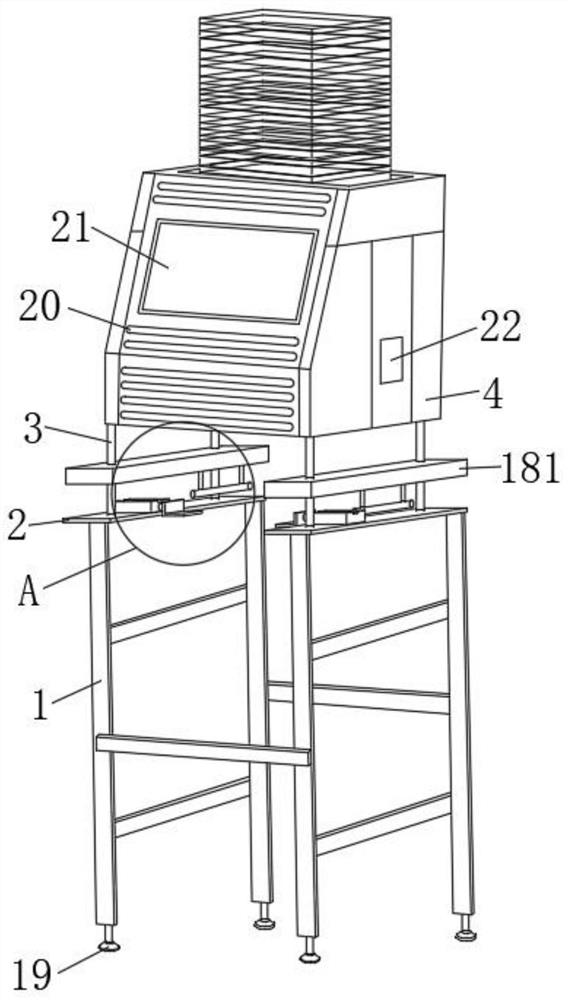

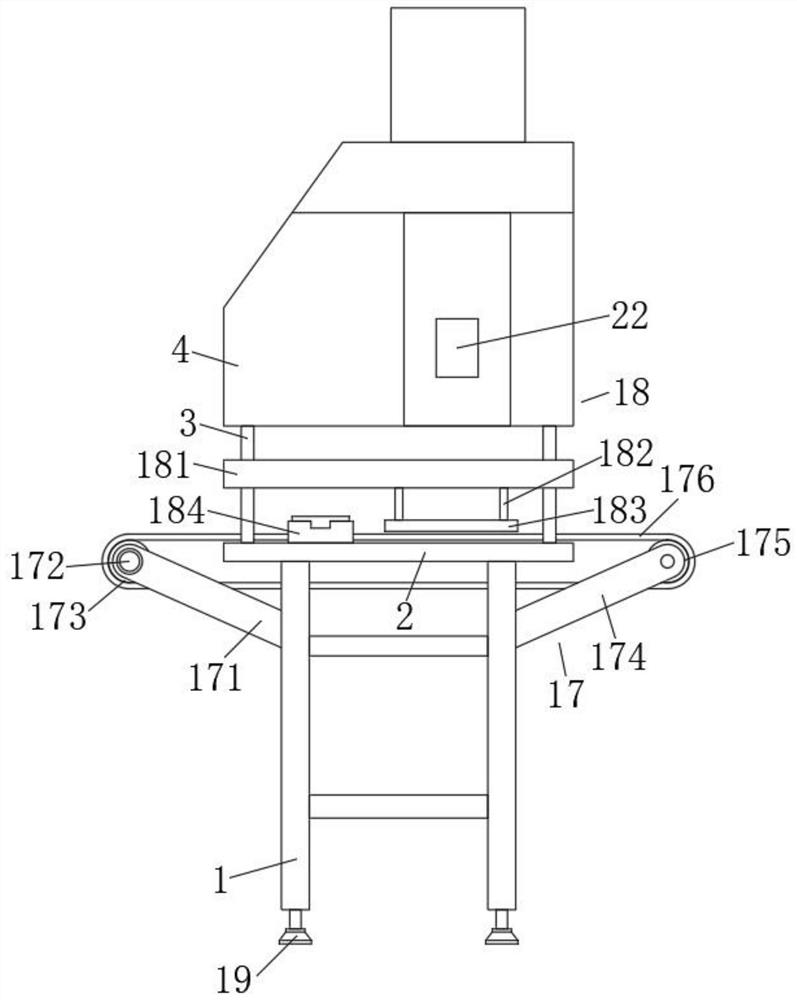

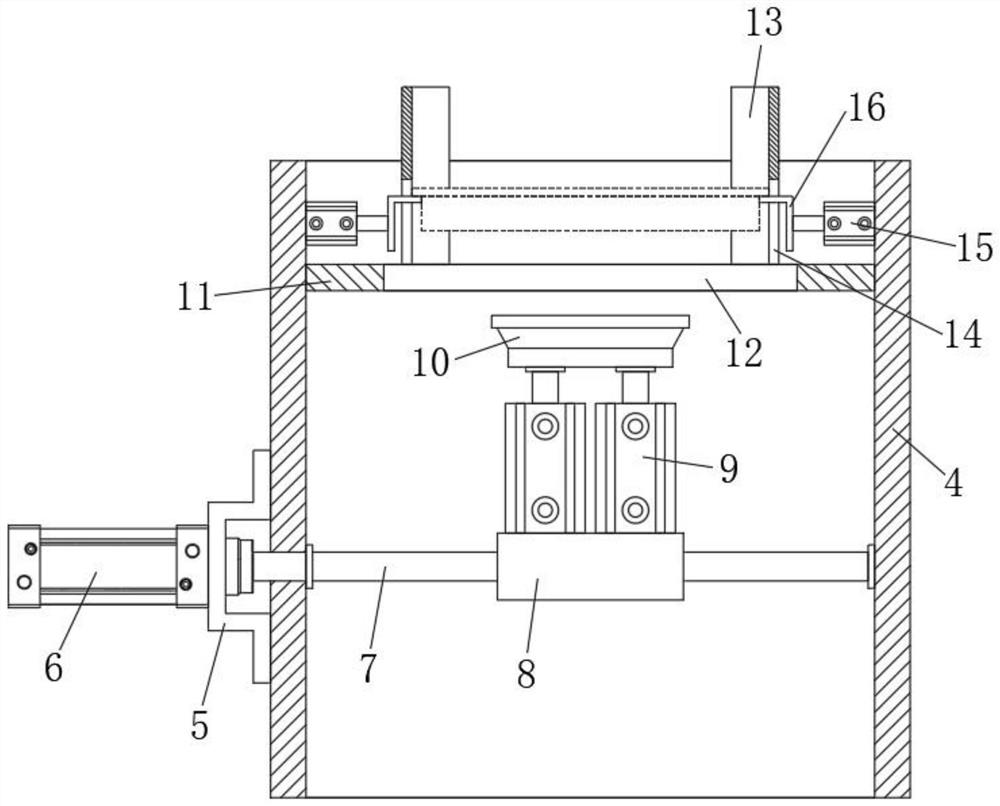

[0025] Such as Figure 1-5 As shown, the present invention provides an automatic box lid machine, comprising a frame 1, both ends of the top of the frame 1 are fixedly connected with a horizontal plate 2, and both ends of the top of the horizontal plate 2 are fixedly connected with a fixed rod 3. The tops of the four fixed rods 3 are fixedly connected to the organic body 4, through the cooperation between the fixed rods 3 and the horizontal plate 2, it is convenient to better install and fix the body 4 on the top of the frame 1; the body The outer side of 4 is fixedly connected with a mounting plate 5, and the outer side of the mounting plate 5 is fixedly installed with a servo motor 6, through the mounting plate 5, it is convenient to better install and fix the servo motor 6; the output shaft of the servo motor 6 is installed through the The plate 5 extends to the inside of the body 4 and is fixedly connected with a rotating rod 7. The end of the rotating rod 7 away from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com