Garbage classifying equipment with intelligent remote control function

A remote control and garbage sorting technology, which is applied in the direction of garbage cans, garbage collection, lighting and heating equipment, etc., can solve the problems of blockage of filter blocks, lack of adjustment function of filter blocks, and insufficient flexibility in use, etc. Weight and adhesion, easy sorting and transportation, even effect of laying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

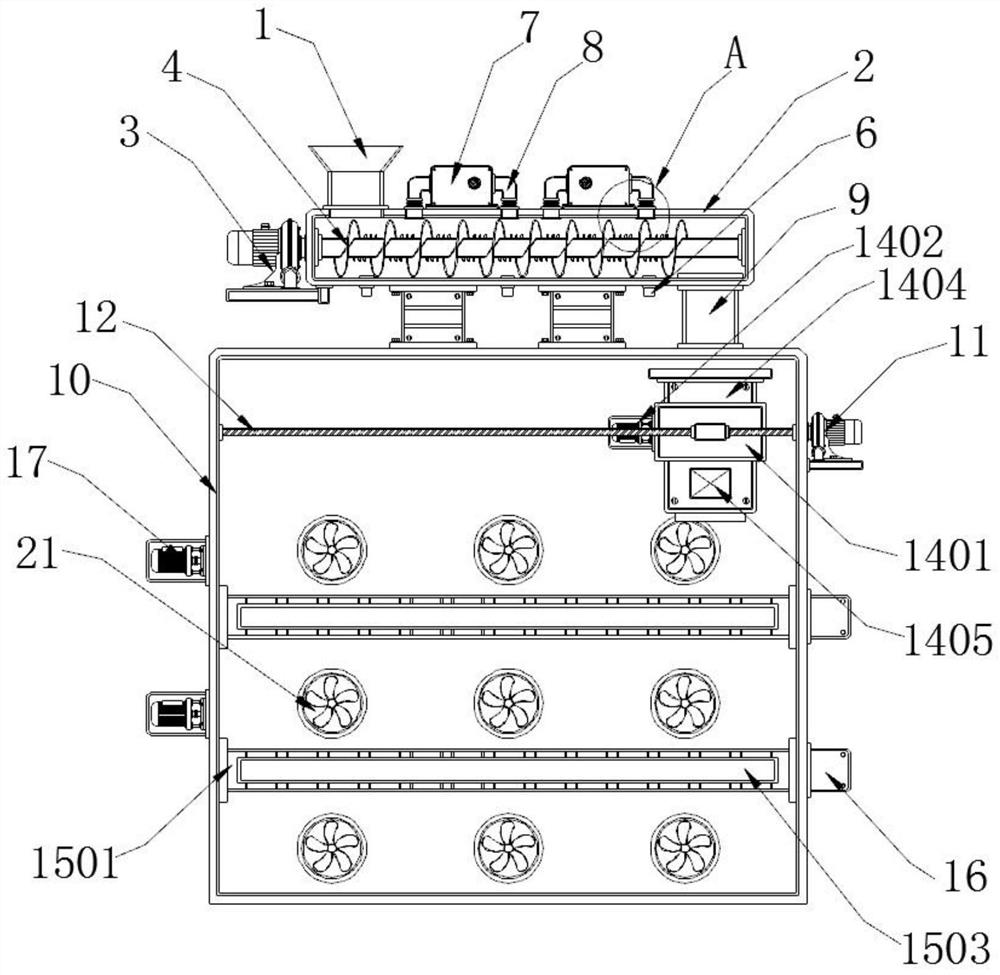

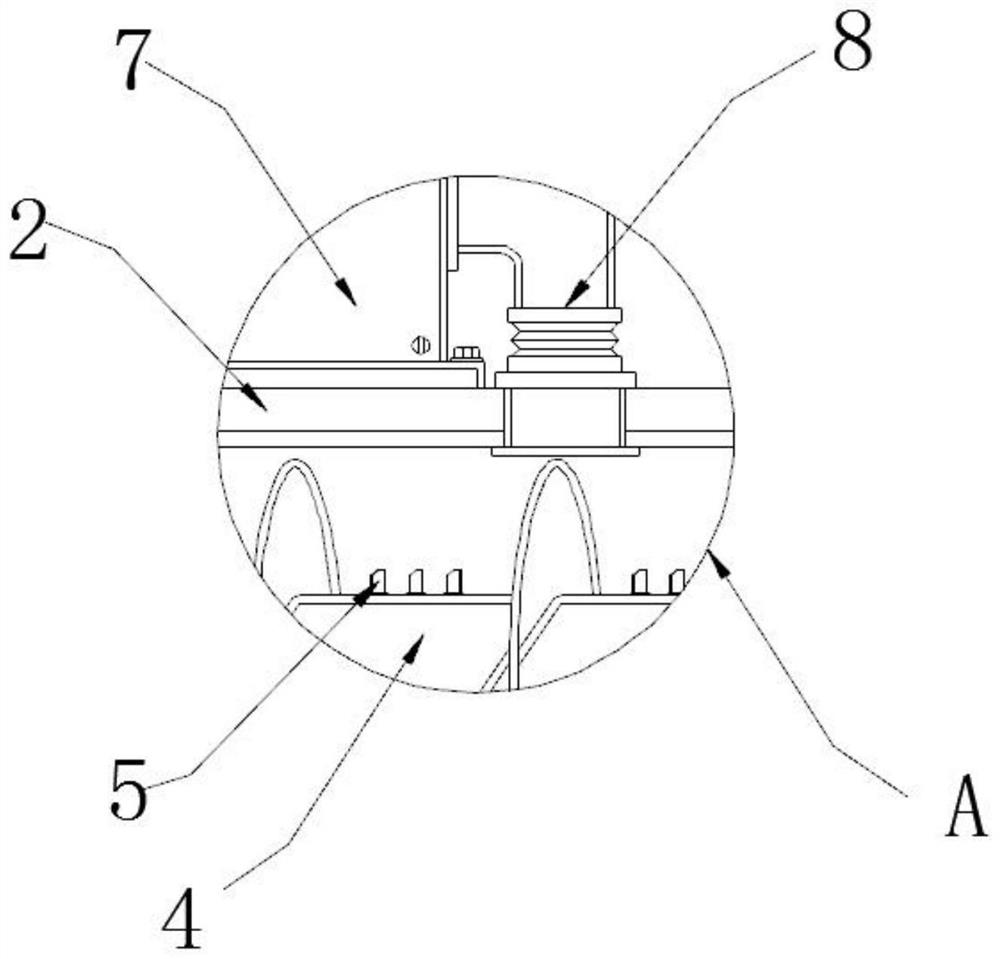

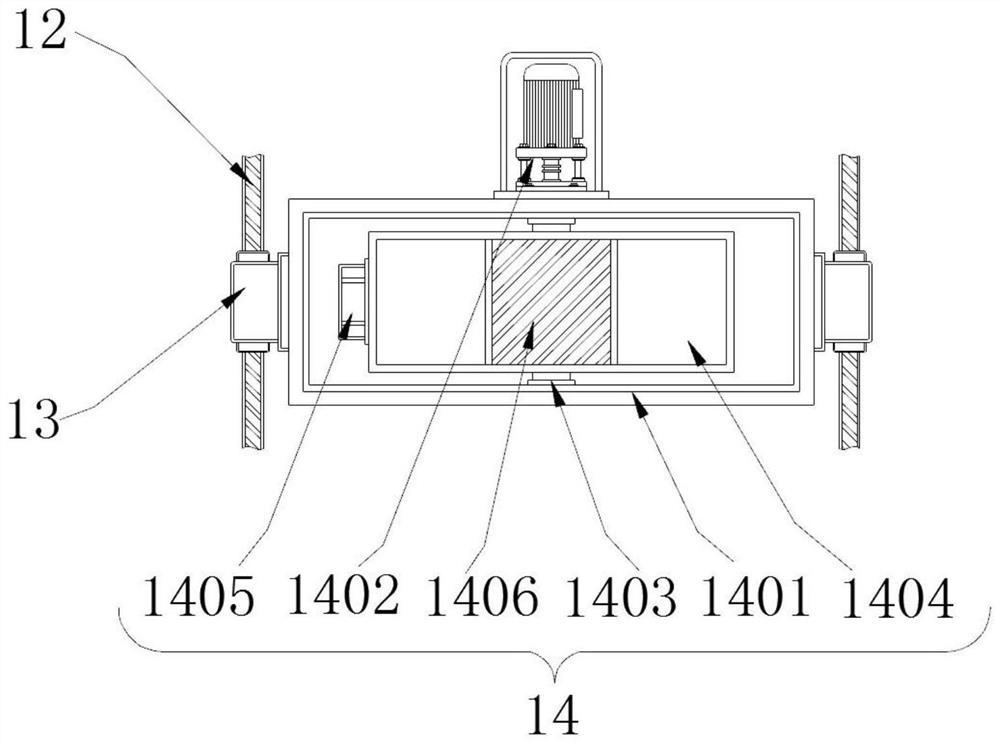

[0028] see Figure 1-6 , the present invention provides a technical solution: a garbage sorting device with an intelligent remote control function, comprising a material inlet 1, a feeding roller 4 and a sorting assembly 15, and a material feeding box 2 is arranged outside the bottom of the material inlet 1, And the first motor 3 is arranged on the outside of the left part of the feeding box 2, the feeding roller 4 is arranged at the inner middle end of the feeding box 2, and the outer surface of the feeding roller 4 is connected with a cutting knife 5, and the outer surface of the feeding box 2 The outside of the bottom is connected with a water outlet pipe 6, and the top outside of the feeding box 2 is provided with a heating box 7, and heat transfer pipes 8 are arranged on both sides of the heating box 7, and the right bottom of the feeding box 2 is connected with a feeding pipe 9. And the end of feeding pipe 9 is provided with sorting box 10, and the right side top of sort...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com