A kind of bio-based antibacterial ultraviolet fluorescent coating and preparation method thereof

A fluorescent coating, bio-based technology, applied in luminescent coatings, antifouling/underwater coatings, coatings, etc., can solve problems such as harm to human health, and achieve the effects of low cost, short process flow and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of bio-based antibacterial ultraviolet fluorescent coating, the preparation method is carried out according to the following steps:

[0041] S1. Dissolve 5',5-diallyl-2,2'-biphenol and 1,6-hexanedithiol in an organic solvent at a stirring speed of 200-400r / min at room temperature to obtain mixture.

[0042] Wherein, the mass fraction ratio of 5',5-diallyl-2,2'-biphenol and 1,6-hexanedithiol is 65-80: 20-35, and the mass fraction of solute and solvent The ratio is 10-20:80-90.

[0043]The organic solvent is one of toluene or acetone or DMSO or DMF.

[0044] S2. Add catalyst b to the mixed solution obtained in step S1, and the mass ratio of catalyst b to solute in S1 is 1-5:100; and the temperature is raised to 60-100 ° C, stirring at 600-800 r / min The reaction rate is 4-6h.

[0045] S3. The obtained product solution after the reaction of step S2 is added to the cyclohexane solution, stirred for 20min at a speed of 500~1000r / min, and then left s...

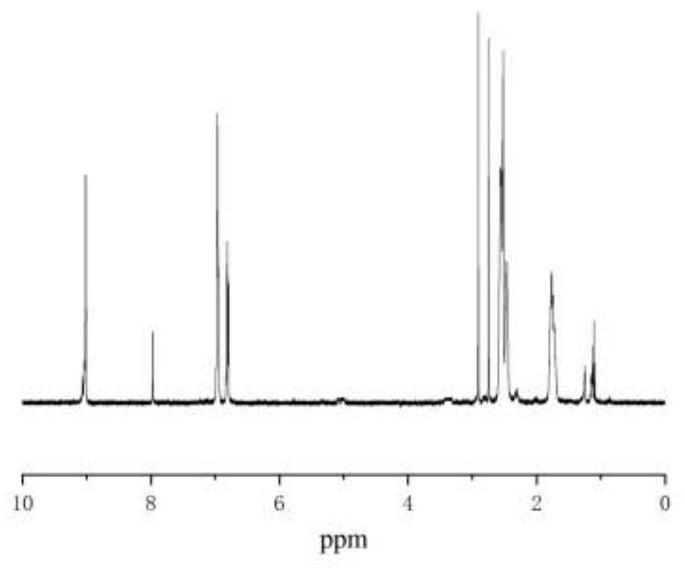

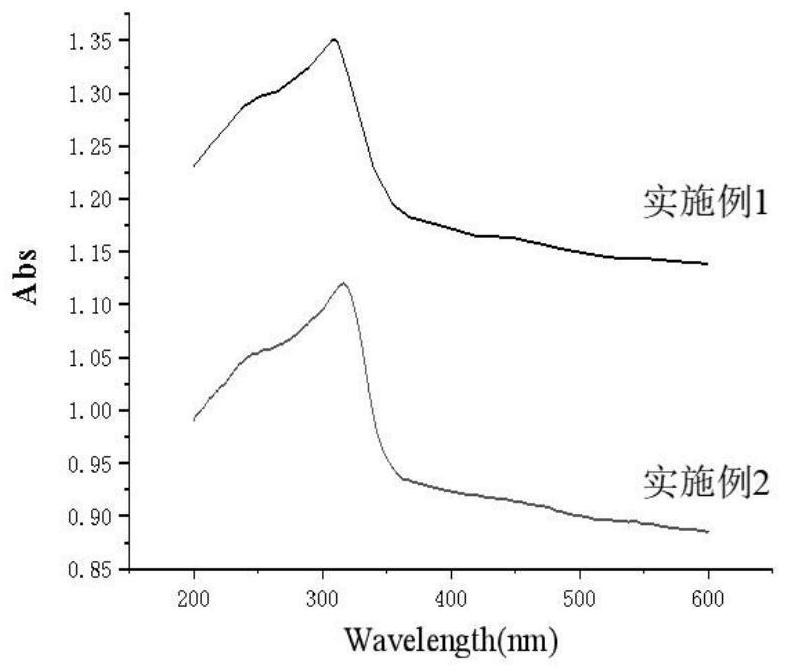

Embodiment 1

[0054] Preparation method of bio-based antibacterial ultraviolet fluorescent paint.

[0055] Prepare as above:

[0056] S1. Dissolve 6.5g 5',5-diallyl-2,2'-biphenol and 3.5g 1,6-hexanedithiol in 90g toluene at room temperature at a stirring speed of 200r / min , to obtain a mixed solution.

[0057] S2. Add 100 mg of azobisisobutyronitrile to the mixed solvent obtained in step S1, raise the temperature to 60 °C, and react at a stirring speed of 600 r / min for 6 h.

[0058] S3. The product solution obtained in step S2 was added to 900 g of cyclohexane solution, stirred at a speed of 500 r / min for 20 min, and then allowed to stand.

[0059] S4. Remove the supernatant of the solution obtained in step S3, collect the gelatinous precipitate in the lower layer, and dry at 30° C. and 0.09 Mpa for 30 min to obtain a prepolymer.

[0060] S5. The prepolymer obtained in step S4 and 1.1 g of trimethylolpropane tris(3-mercaptopropionic acid) ester are stirred uniformly at 80° C. to be fully...

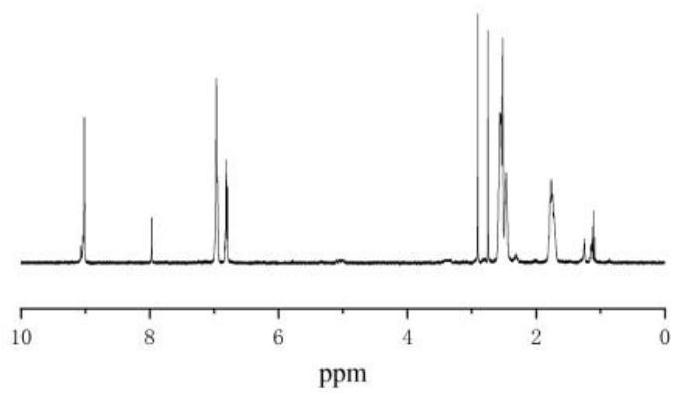

Embodiment 2

[0068] Preparation method of bio-based antibacterial ultraviolet fluorescent paint.

[0069] Prepare as above:

[0070] S1. Dissolve 8.0g 5',5-diallyl-2,2'-biphenol and 2.0g 1,6-hexanedithiol in 100g toluene at a stirring speed of 200r / min at room temperature , to obtain a mixed solution.

[0071] S2. Add 500 mg of azobisisobutyronitrile to the mixed solvent obtained in step S1, raise the temperature to 100 °C, and react at a stirring speed of 600 r / min for 4 h.

[0072] S3. The product solution obtained in step S2 was added to 1900 g of cyclohexane solution, stirred at a speed of 500 r / min for 20 min, and then allowed to stand.

[0073] S4. Remove the supernatant of the solution obtained in step S3, collect the gelatinous precipitate in the lower layer, and dry at 30° C. and 0.09 Mpa for 30 min to obtain a prepolymer.

[0074] S5. The prepolymer obtained in step S4 and 2.5 g of trimethylolpropane tris(3-mercaptopropionic acid) ester are stirred uniformly at 80° C. to be fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| UV absorbance | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com