Gd-containing duplex stainless steel with excellent neutron absorption performance and preparation method of Gd-containing duplex stainless steel

A technology of duplex stainless steel and absorption performance, which is applied in the direction of furnace type, process efficiency improvement, furnace, etc., can solve the problems of material processing performance and mechanical performance damage, natural B neutron absorption limited ability, manufacturing cost increase, etc., to achieve High economy, low cost, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

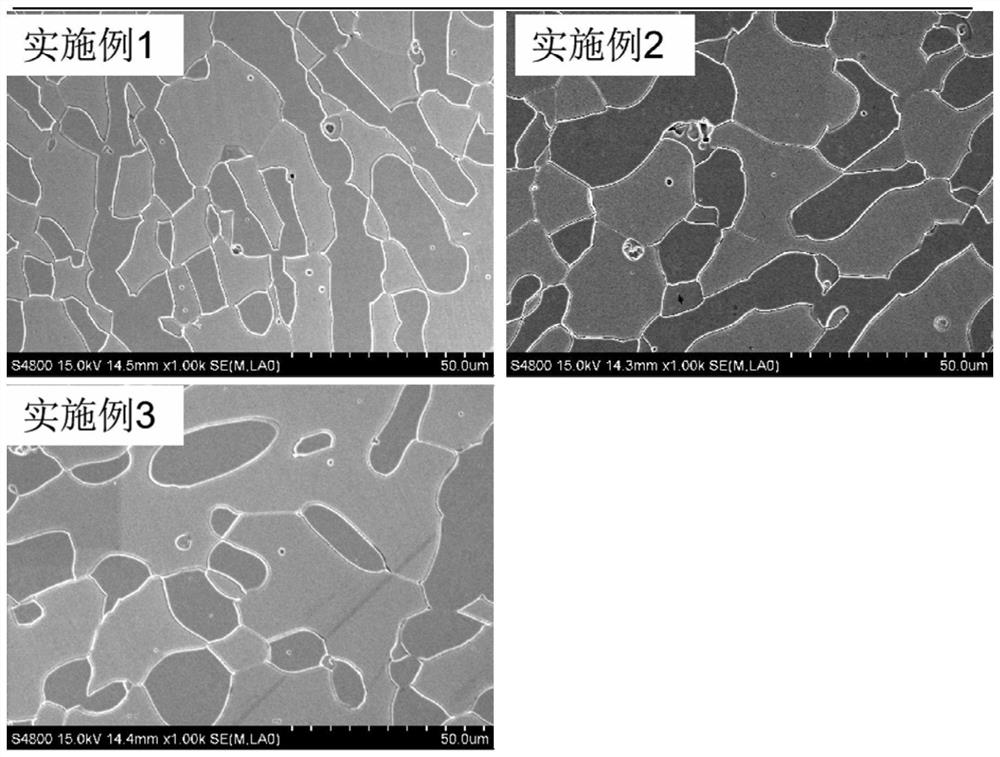

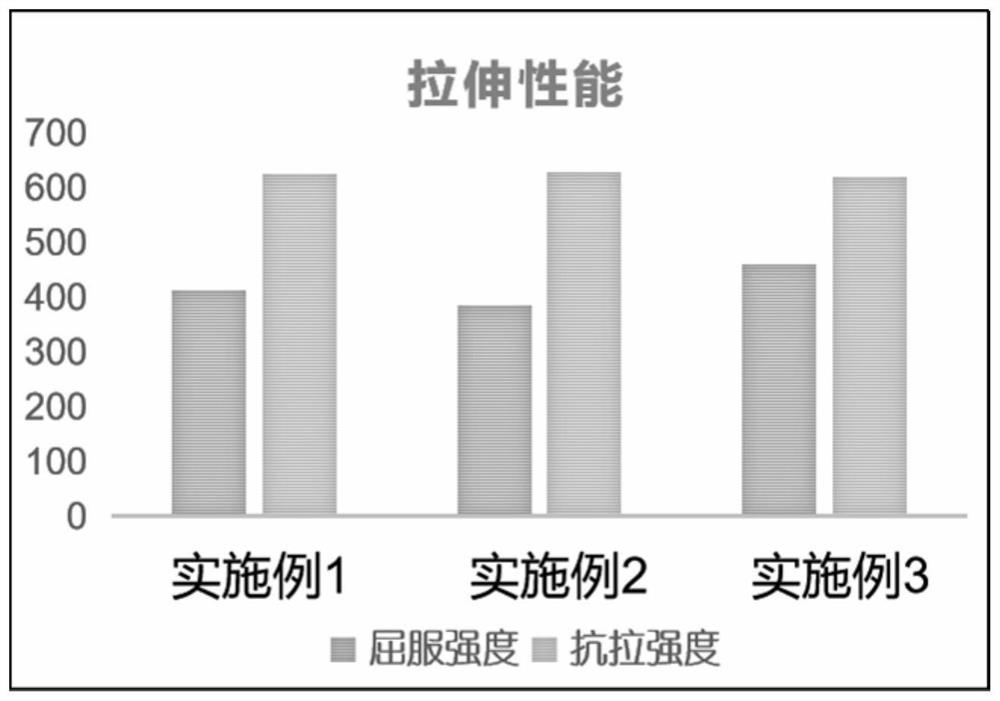

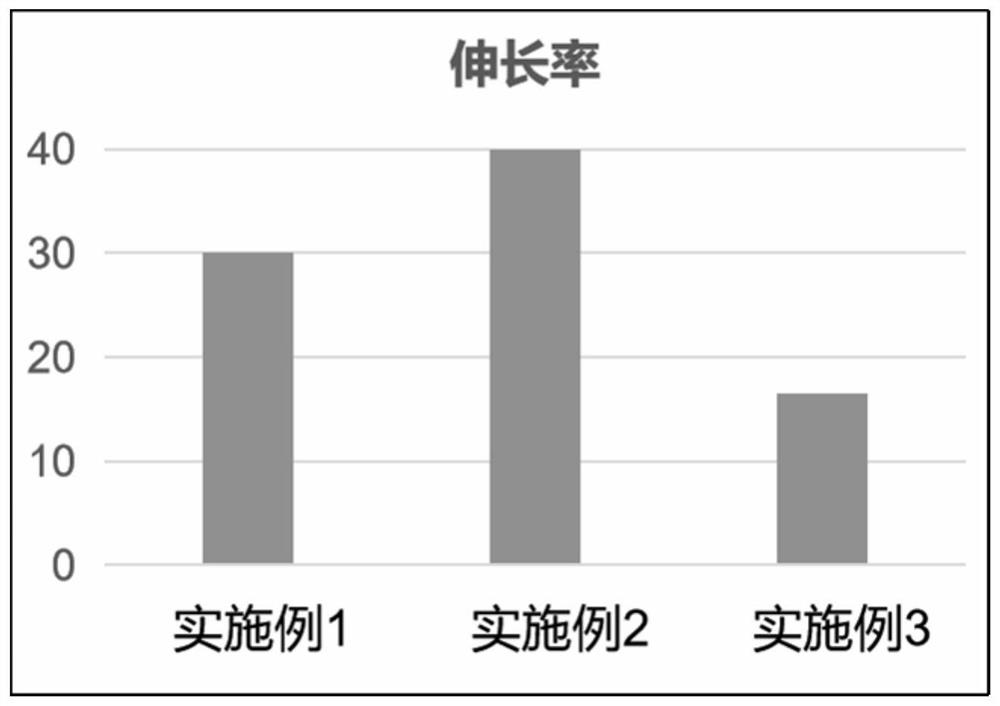

[0037] The present invention is described in detail below in conjunction with accompanying drawing and embodiment.

[0038] The chemical composition of stainless steel in Examples 1-3 and Comparative Examples 1-3 is shown in Table 1.

[0039] The composition of the Gd-containing duplex stainless steel alloy of table 1 embodiment and comparative example

[0040]

[0041] Stainless steel is prepared according to the following process in embodiment 1-3 and comparative example 1-3:

[0042] Pure metal raw materials Fe, Cr, Ni, Mo, Mn, and some C are mixed in a vacuum induction furnace and placed in a crucible to evacuate and smelt. During the smelting period, the efficiency of carbon deoxidation and nitrogen is enhanced by relying on a high vacuum environment and low melting rate. After the steel is liquefied and cleared, the balance of C and Al is added after the steel is fully melted and then refined. The refining temperature is 1500°C and the holding time is 30 minutes. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com