A kind of al-b4c-b neutron absorbing material and preparation method thereof

An absorbing material, al-b4c-b technology, applied in radiation protection neutron absorbing materials, nuclear radiation protection, can solve the inability to ensure neutron shielding performance, increase the difficulty of composite plate preparation, poor processing performance and plasticity, etc. problems, achieve excellent neutron absorption performance, reduce preparation difficulty, and achieve high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

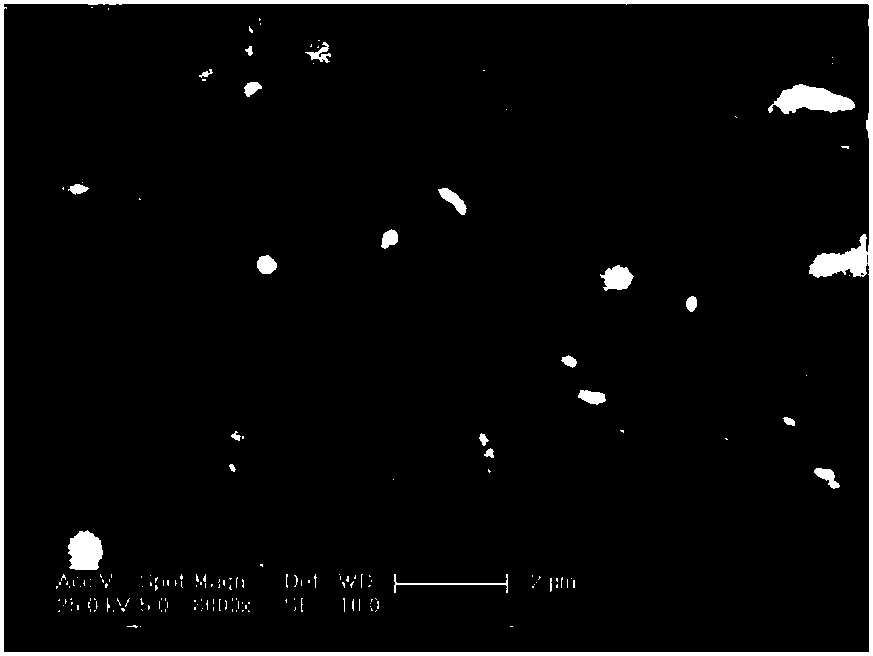

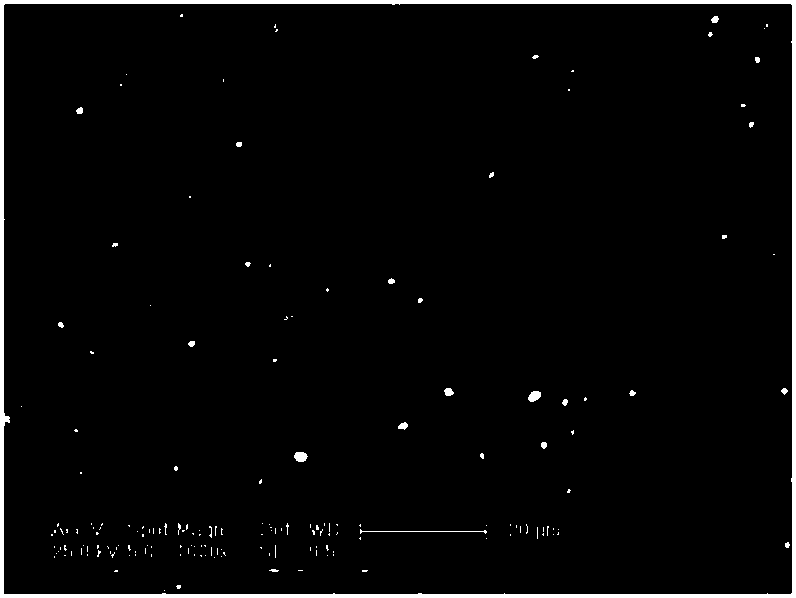

Image

Examples

Embodiment 1

[0054] Step 1 Weighing: Weigh 20% of B by mass fraction 4 C powder, 0.5% B powder, 79.5% 5083 aluminum alloy powder.

[0055] Step 2 Ball milling and mixing: Mix the powders obtained in Step 1 together, use a planetary ball mill for mixing, add analytical pure alcohol until the surface of the mixed powder is submerged, the speed is 180r / min, and the ball milling time is 6 hours to obtain a mixed powder body; put the mixed powder into a constant temperature drying oven at 70°C to keep warm and dry for 30 hours to obtain a dry mixed powder.

[0056] Step 3 Cold isostatic pressing: put the dry powder obtained in step 2 into the mold, vacuumize to maintain the vacuum degree at about 8Pa, and then carry out cold isostatic pressing under the condition of 180MPa and holding pressure for 10 minutes to form a billet Body, green body density is 83%.

[0057] Step 4 Packing and high-temperature degassing: remove the mold from the body obtained in step 3, and weld it with an iron plate ...

Embodiment 2

[0060] The present embodiment is different from Example 1 in that: take 20% B by mass fraction 4 C powder, 1.0% B powder, 79.0% 5083 aluminum alloy powder. Others are the same as in Example 1.

Embodiment 3

[0062] The present embodiment is different from Example 1 in that: take 20% B by mass fraction 4 C powder, 1.5% B powder, 78.5% 5083 aluminum alloy powder. Others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com