A kind of preparation method of neutron absorbing material

A technology of absorbing material and neutron absorbing agent, applied in the field of neutron absorbing material and its preparation, to achieve the effects of excellent mechanical properties, easy processing and molding, and excellent neutron absorbing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

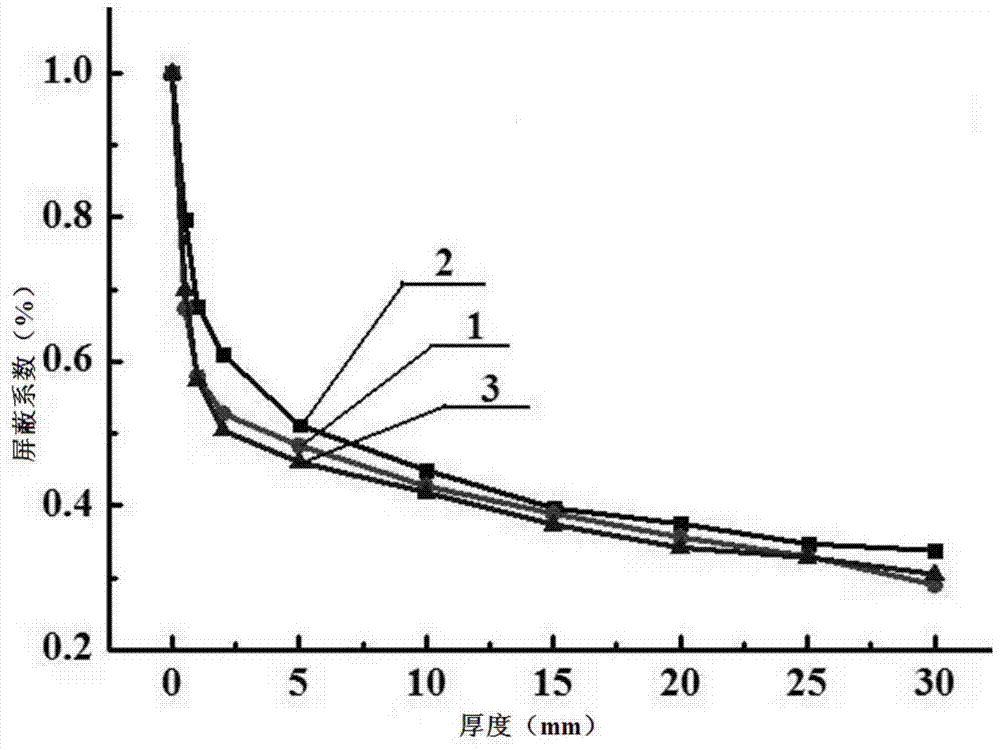

[0020] Specific Embodiment 1: In this embodiment, a neutron absorbing material is made of 10% to 20% boron carbide, 1% to 2% neutron absorber and 78% to 89% aluminum-containing material by volume fraction; Boron is boron carbide particles with a particle size of 17.5 μm or boron carbide particles with a particle size of 5 μm; the aluminum-containing material is aluminum or aluminum alloy.

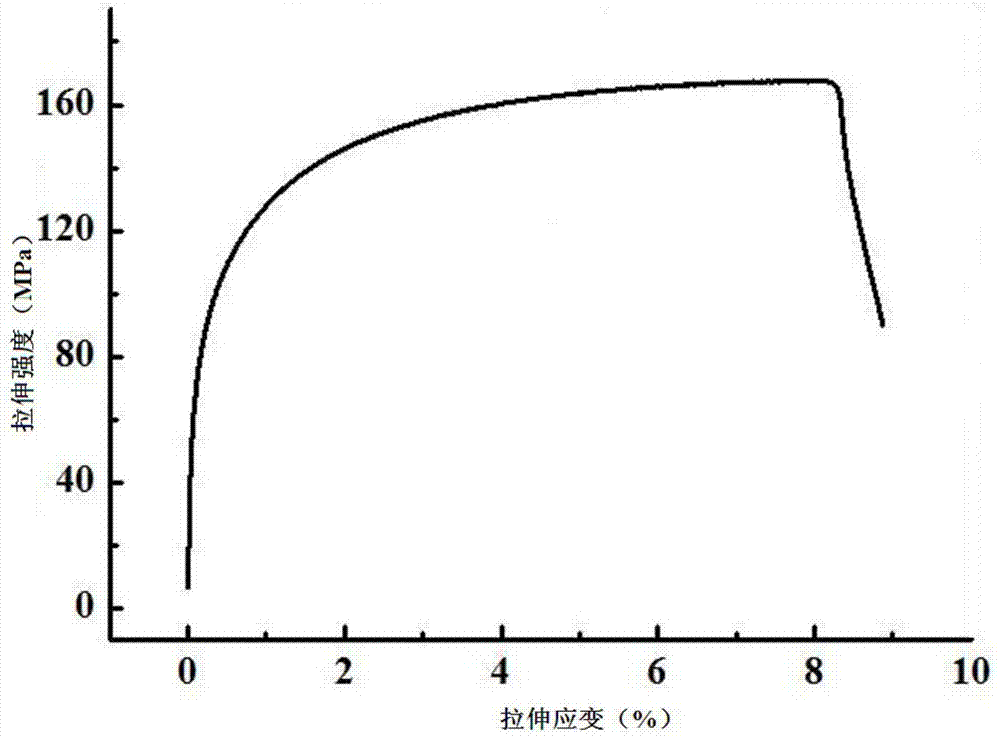

[0021] The neutron absorbing material of this embodiment has a high density, and since the boron carbide content is about 10% to 20%, it not only has a good reinforcing effect, but also can exert the plasticity of the aluminum alloy, and the composite material has good plasticity and is easy to process Forming; at the same time, due to the addition of element particles with a high neutron absorption cross section in the neutron absorbing material, the neutron absorbing ability of the composite material is improved; the prepared neutron absorbing material has excellent mechanical properties, ...

specific Embodiment approach 2

[0022] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the neutron absorbing material is made of 14% to 16% boron carbide, 1% neutron absorber and 83% to 85% aluminum-containing materials by volume fraction . Others are the same as the first embodiment.

specific Embodiment approach 3

[0023] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the neutron absorbing material is made of 15% boron carbide, 1% neutron absorber and 84% aluminum-containing material by volume fraction. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com