Electroplating processing equipment

A technology of processing equipment and cleaning cloth, which is applied in the electrolysis process, electrolysis components, cells, etc., can solve the problem of rough coating on the surface of the workpiece, achieve fast drying speed, reduce the risk of material hole shrinkage, and improve the effect of rough coating on the surface of the workpiece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

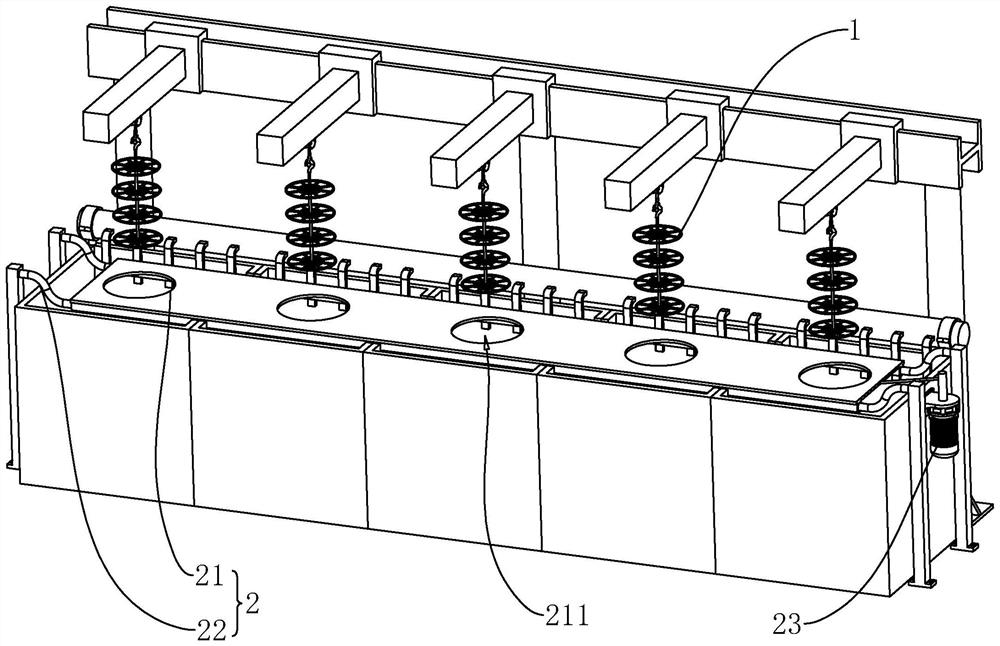

[0041] refer to figure 1A kind of electroplating processing equipment includes a hanger 1 for hanging workpieces to be electroplated and a cleaning device 2 for cleaning the surface particles of the electroplating solution. The hanger 1 is suspended on lifting mechanisms such as driving and cranes. When the electroplating operation is required, the cleaning device 2 skims off the particles on the surface of the electroplating solution, and then immerses the hanger 1 in the electroplating solution, and then the electroplating operation can be performed, and the problem of rough coating on the surface of the workpiece caused by particles floating on the surface of the electroplating solution can be improved .

[0042] refer to figure 1 Specifically, the cleaning device 2 includes a cleaning cloth 21, a guide rail 22 and a driving mechanism 23, wherein the cleaning cloth 21 is made of a corrosion-resistant material, which may be polyester cloth or Oxford cloth. The cloth surfac...

Embodiment 2

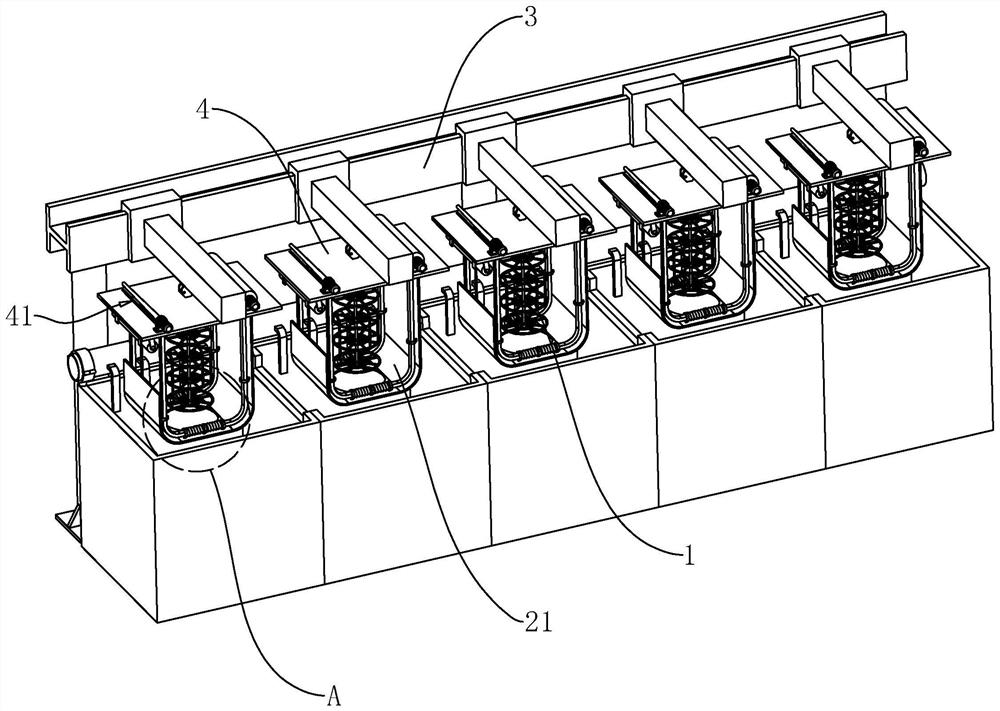

[0047] refer to figure 2 , The difference between this embodiment and Embodiment 1 is that an electroplating processing equipment further includes a crane body 3 for driving the hanger 1 into the electroplating solution, and the hanger 1 is suspended from the crane body 3 . When the electroplating operation is required, the cleaning cloth 21 skims off the particles on the surface of the electroplating solution, and then the crane body 3 immerses the hanger 1 in the electroplating solution, and then the electroplating operation can be performed.

[0048] refer to figure 2 , specifically, the carriage body 3 is welded with a bearing plate 4 for suspension by the hanger 1, the bearing plate 4 is made of a non-conductive material, the surface of the bearing plate 4 facing the electroplating solution is defined as the lower side of the bearing plate 4, and the bearing plate 4 is The surface facing away from the plating solution is defined as the upper side of the carrier plate 4...

Embodiment 3

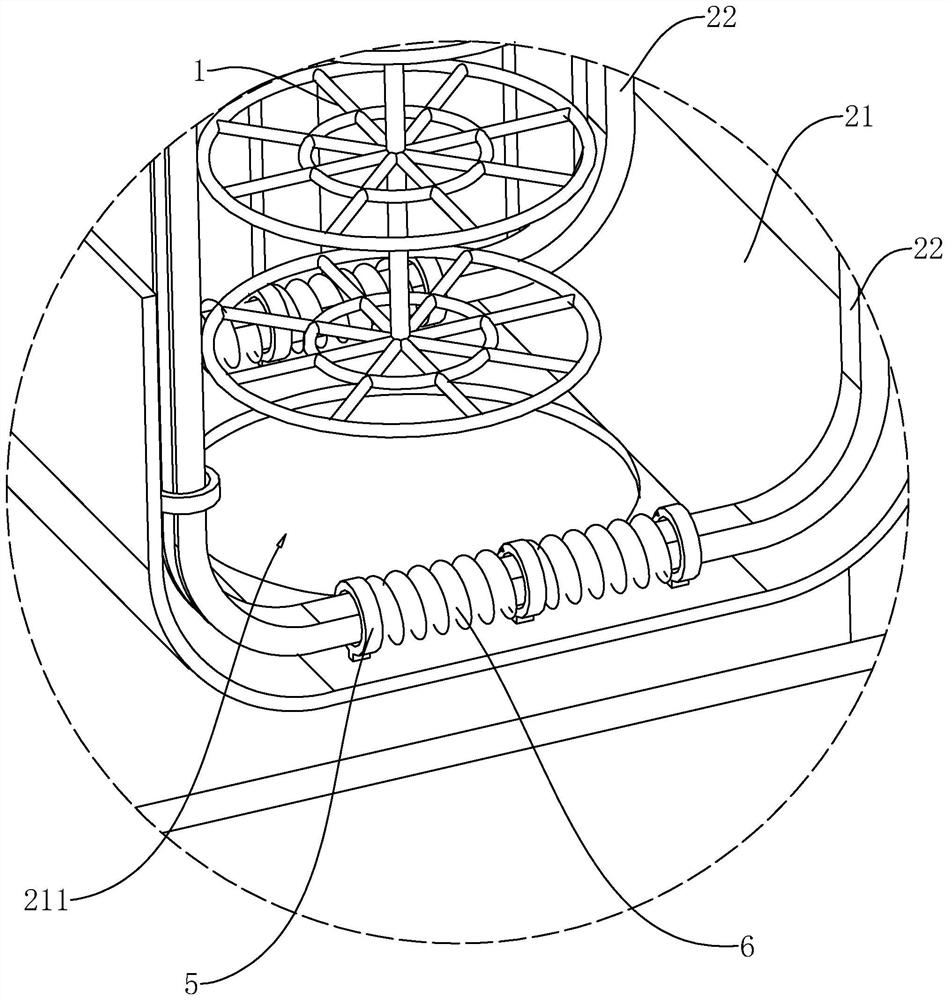

[0059] refer to image 3 , Figure 5 The difference between this embodiment and Embodiment 2 is that it provides a solution to replace the compression spring 6 to limit the deformation of the material hole 211. Specifically, the surface of the cleaning cloth 21 is bonded and fixed with a flexible bone strip 10, and the flexible bone strip 10 Used to force the cleaning cloth 21 to stretch on the surface of the electroplating solution. The flexible bone strip 10 can be a corrosion-resistant rubber strip or a corrosion-resistant plastic strip. The flexible bone strip 10 extends along the length direction of the guide rail 22 , and the elasticity and ductility of the flexible bone strip 10 can reduce the risk of wrinkling of the cleaning cloth 21 , thereby reducing the risk of deformation of the material hole 211 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com